Abstract

The frequency equation of carbon-nanotube-based cantilever sensor with an attached mass is derived analytically using nonlocal elasticity theory. According to the equation, the relationship between the frequency shift of the sensor and the attached mass can be obtained. When the nonlocal effect is not taken into account, the variation of frequency shift with the attached mass on the sensor is compared with the previous study. According to this study, the result shows that the frequency shift of the sensor increases with increasing the attached mass. When the attached mass is small compared with that of the sensor, the nonlocal effect is obvious and increasing nonlocal parameter decreases the frequency shift of the sensor. In addition, when the location of the attached mass is closer to the free end, the frequency shift is more significant and that makes the sensor reveal more sensitive. When the attached mass is small, a high sensitivity is obtained.

Keywords: Carbon nanotube, Mass sensor, Nonlocal elasticity theory, Frequency shift

Introduction

Carbon nanotube (CNT) have many potential applications in nanobiological devices and nanomechanical systems because of excellent mechanical properties, chemical and thermal stability, and hollow geometry [1-4]. In addition, the CNT is ultralight and is highly sensitive to its environment changes. Therefore, many researchers have explored the potential of using CNT as nanomechanical resonators in atomic-scale mass sensor [5-7]. For example, Chiu et al. [6] utilized the detection of shifts in the resonance frequency of the nanotubes to measure nanotube resonator vibration characteristics.

The atomic-scale mass sensing with a resonator is based on the fact that the resonant frequency is sensitive to the attached mass. The attached mass causes a shift to the resonant frequency of resonator. In addition, the shift in resonant frequency is associated with the location of attached mass. To analyze the effects of adsorbed mass and its location on the resonant frequency of CNT, the continuum models based on beam as well as shell was used [8]. Recently, Dai et al. [9] studied the nanomechanical mass detection using nonlinear oscillators based on continuum elastic model and obtained that nonlinear oscillation leads to the unique resonant frequency shift due to mass adsorption, quite different from that in harmonic oscillation. The ultimate goal of a resonator sensor is single molecule detection capability. Chowdhury et al. [10] presented an equivalent approximation model to analyze frequency shift of a single-walled carbon nanotube (SWCNT) due to an attached particle fixed at a location.

It is more useful for a mass sensor to simultaneously detect the mass and position of the attached particle. In this Letter, frequency shift of carbon-nanotube-based sensor with an attached mass is studied using nonlocal elasticity theory, which is a modified classical elasticity theory. This theory with long-range interactions is often applied to analyze the vibration behaviour of CNT [11-13]. In addition, the effects of nonlocal parameter, attached mass and its location on the frequency shift of a cantilevered SWCNT are analyzed.

Analysis

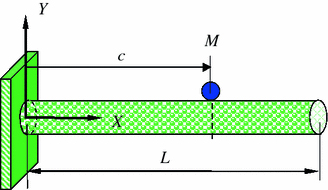

A schematic diagram of a SWCNT with an attached mass M located at c from the fixed end is described as a cantilever beam as depicted in Fig. 1. The SWCNT with length L has an equivalent bending rigidity EI, the volume density ρ, the cross-sectional area A, and transverse displacement Y depend on the spatial coordinate X and time t. Based on nonlocal elasticity theory [14], the governing equation of transverse vibration for the SWCNT can be expressed as

Figure 1.

A cantilevered nanotube-based mass sensor with an attached mass

where e0a is the nonlocal parameter, and it is used to modify the classical elasticity theory and is limited to apply to a device on the nanometer scale.

The harmonic solution of the governing equation can be assumed as

where ω is the angular frequency.

By introducing the dimensionless parameters x = X/L, and substituting Eq. 2 into Eq. 1, one obtain

where

The corresponding boundary conditions are

where m = M/ρAL and ξ = c/L are the dimensionless mass and position of the attached mass, respectively; w1 and w2 are the dimensionless transverse displacements on the left and right sides of the attached mass, respectively.

The boundary conditions given by Eq. 5 correspond to conditions of zero displacement and the zero slope at fixed end (x = 0), Eqs. 6 and 7 are zero moment and the zero shear force at free end (x = 1), respectively. Eqs. 8, 9, 10 and 11 are the compatibility conditions at the location of the attached mass [15].

The general solutions of Eq. 3 for the SWCNT with attached mass are

where

|

and C1, C2, C3,…C8 are constants.

Substituting Eqs. 12 and 13 into Eqs. 5, 6, 7, 8, 9, 10 and 11, we can obtain the following matrix form:

where

|

in which

|

Therefore, the characteristic equation is given by

where  is the determinant of the matrix

is the determinant of the matrix

According to dimensionless variables  given in Eq. 4, the frequency is

given in Eq. 4, the frequency is

|

Meanwhile, the dimensionless sensitivity σm can be obtained from the following equation:

|

While neglecting the nonlocal effect (ɛ = 0), and assuming the attached mass at free end (ξ = 1), the frequency equation for a cantilevered SWCNT with attached mass can be reduced. Then the frequency expressed in dimensionless wave number k can be obtained by solving the following equation:

Furthermore, neglecting the attached mass (m = 0), the dimensionless wave number k can be obtained from

The above frequency equation expressed in dimensionless wave number k for the free vibration of a cantilever beam can also be found in the textbook about vibration [16].

Results and Discussion

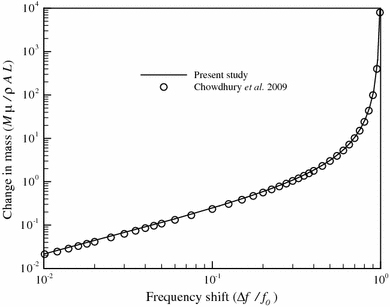

Based on nonlocal elasticity theory, we have derived the frequency equation to analyze the effects of nonlocal parameter, e0a/L, attached mass and its location, c/L, on the frequency shift of carbon-nanotube-based mass sensor. According to the equation, the relationship between the dimensionless frequency shift and dimensionless added mass on the cantilever mass sensor for mode 1 with c/L = 1 and e0a/L = 0 is obtained and shown in Fig. 2. The dimensionless frequency shift is defined as the ratio of the difference between the fundamental frequency of a nanotube with and without attached mass, to that without attached mass, f0. To compare with a previous study, we use the same normalized mass as described in Ref. [10], where the value of parameter μ is 140/33. It can be seen that the comparison of the two results shows good agreement. However, the previous work that assumes a fixed location of attached mass (i.e., c/L = 1); and it is only a special case of this study. In addition, the nonlocal effect was not taken into account in their analysis (i.e., e0a/L = 0).

to that without attached mass, f0. To compare with a previous study, we use the same normalized mass as described in Ref. [10], where the value of parameter μ is 140/33. It can be seen that the comparison of the two results shows good agreement. However, the previous work that assumes a fixed location of attached mass (i.e., c/L = 1); and it is only a special case of this study. In addition, the nonlocal effect was not taken into account in their analysis (i.e., e0a/L = 0).

Figure 2.

The relationship between the dimensionless frequency shift and dimensionless added mass on the mass sensor for mode 1 with c/L = 1 and e0a/L = 0

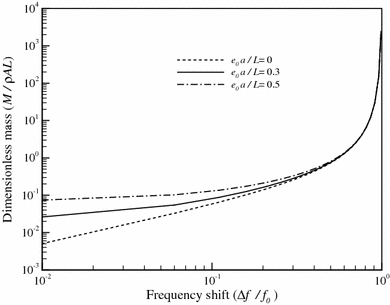

Conventional continuum mechanics theories assume that the stress at a point is a function of strain at that point in local elasticity. Material behaviors predicted by such a local theory are assumed to be scale-independence in the constitutive law. When the continuum elasticity theory is applied to the analysis of the nano-scale structures, it is found to be inadequate because of ignoring the small scale effect. For improving this situation, the nonlocal elasticity theory was presented by Eringen [14]. The theory assumes that the stress at a given point is a function of strain at every point in the body. Accordingly, the small scale effect can be taken into account in the constitutive equation. Figure 3 depicts the effect of nonlocal parameter on the frequency shift of the cantilever sensor with attached mass for c/L = 1. It can be seen that the frequency shift of the sensor increases with increasing the attached mass. Based on the nonlocal elasticity theory, long-range interactions are taken account in the analysis that makes the sensor stiffer. Therefore, it can be found that increasing the nonlocal parameter increases the frequency shift. The trend is obvious when the attached mass is small compared with that of the sensor.

Figure 3.

The effect of nonlocal parameter on the frequency shift of the sensor with attached mass for c/L = 1

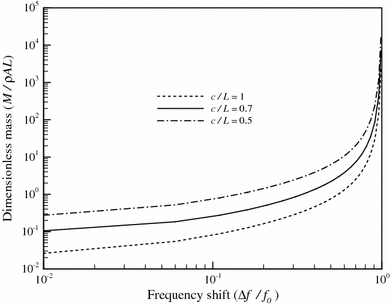

In addition, the location of attached mass can influence on the changes in frequency of the mass sensor. Figure 4 illustrates the effect of location of attached mass, c/L, on the frequency shift of the cantilever mass sensor for e0a/L = 0.3. It can be seen that the effect of the location of attached mass on the frequency shift of the mass sensor is significant. Increasing the value of c/L increases the frequency shift. This is because the frequency of the sensor with the attached mass decreases with increasing the particle mass. Increasing the value of c/L is equivalent to an increase of the particle mass at the same location.

Figure 4.

The effect of location of attached mass on the frequency shift of the sensor for e0a/L = 0.3

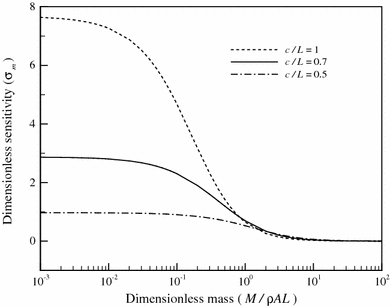

It is important to know the sensitivity of the mass sensor. The sensitivity of the sensor is defined as the ratio of the variation of the frequency shift to the variation of the attached mass. Figure 5 shows the effect of location of attached mass on the sensitivity of the sensor for e0a/L = 0.3. It can be seen from Fig. 4 that the frequency shift is linearly downward with decreasing mass. Therefore, a high sensitivity is revealed when the attached mass is small. In addition, it can be observed that the sensitivity of the sensor is strongly dependent on the location of attached mass, c/L. The sensitivity of the sensor quickly drops as the value of c/L decreased. This is because the frequency shift decreases with decreasing the value of c/L.

Figure 5.

The effect of location of attached mass on the sensitivity of the sensor for e0a/L = 0.3

Conclusions

In this Letter, the frequency shift and sensitivity of carbon-nanotube-based sensor with an attached mass was studied using nonlocal elasticity theory. The relationship equation between the frequency shift of the sensor and the attached mass was derived analytically. When the nonlocal effect was not taken into account, the result was compared with the previous study, which adopted a simplified method and obtained an approximate result. According to this study, the result showed that increasing the nonlocal parameter obviously decreased the frequency shift of the sensor when the attached mass was small compared with that of the sensor. The value of frequency shift was larger when the location of the attached mass was closer to the free end. In addition, a high sensitivity of the sensor was revealed when the attached mass was small. However, the sensitivity quickly dropped as the location of the attached mass was closed to the fixed end.

Acknowledgments

The authors wish to thank the National Science Council of the Republic of China in Taiwan for providing financial support for this study under Projects NSC 99-2221-E-168-019 and NSC 99-2221-E-168-031.

Open Access

This article is distributed under the terms of the Creative Commons Attribution Noncommercial License which permits any noncommercial use, distribution, and reproduction in any medium, provided the original author(s) and source are credited.

References

- Dirote EV (ed.), editor. Trends in Nanotechnology Research. Nova Science Publishers, New York; 2004. [Google Scholar]

- O’Connell MJ (ed.), editor. Carbon Nanotubes: Properties and Applications. CRC Press, Boca Raton; 2006. [Google Scholar]

- Yudasaka M, Iijima S, Crespi VH. Topics Appl. 2008. p. 605. COI number [1:CAS:528:DC%2BD1cXltFGjsLo%3D] [DOI]

- Ottenhouse AP (ed.), editor. Carbon Nanotubes: New Research. Nova Science Publishers, New York; 2009. [Google Scholar]

- Garcia-Sanchez D, San Paulo A, Esplandiu MJ, Perez-Murano F, Forro′ L, Aguasca A, Bachtold A. Phys. 2007. p. 085501. COI number [1:STN:280:DC%2BD2sngslOgsA%3D%3D]; Bibcode number [2007PhRvL..99h5501G] [DOI] [PubMed]

- Chiu HY, Hung P, Ch Postma HW, Bockrath M. Nano. 2008. p. 4342. COI number [1:CAS:528:DC%2BD1cXhtl2ns77O]; Bibcode number [2008NanoL...8.4342C] [DOI] [PubMed]

- Huttel AK, Steele GA, Witkamp B, Poot M, Kouwenhoven LP, van der Zant HSJ. Nano. 2009. p. 2547. COI number [1:CAS:528:DC%2BD1MXmslejurs%3D]; Bibcode number [2009NanoL...9.2547H] [DOI] [PubMed]

- Dohn S, Svendsen W, Boisen A, Hansen O. Rev. 2007. p. 103303. COI number [1:STN:280:DC%2BD2snlsFGltA%3D%3D]; Bibcode number [2007RScI...78j3303D] [DOI] [PubMed]

- Dai MD, Eom K, Kim CW. Appl. 2009. p. 203104. Bibcode number [2009ApPhL..95t3104D] [DOI]

- Chowdhury R, Adhikari S, Mitchell J. Physica E. 2009. p. 104. COI number [1:CAS:528:DC%2BD1MXhsFSgs77F]; Bibcode number [2009PhyE...42..104C] [DOI]

- Lee HL, Chang WJ. J. 2008. p. 024302. Bibcode number [2008JAP...103b4302L] [DOI]

- Lee HL, Chang WJ. J. 2009. p. 115302. Bibcode number [2009JPCM...21k5302L] [DOI] [PubMed]

- Lee HL, Chang WJ. Physica E. 2009. p. 529. COI number [1:CAS:528:DC%2BD1MXitF2ltrY%3D]; Bibcode number [2009PhyE...41..529L] [DOI]

- Eringen AC. J. 1983. p. 4703. Bibcode number [1983JAP....54.4703E] [DOI]

- Low KH. Int. 2001. p. 871. [DOI]

- Weaver W, Jr, Timoshenko SP, Young DH. Vibration Problems in Engineering. Wiley, New York; 1990. [Google Scholar]