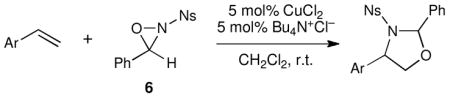

Table 1.

Oxyaminations of styrenes using 6.a

| ||||

|---|---|---|---|---|

| entry | styrene | product | time | yield |

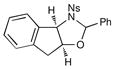

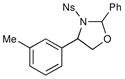

| 1 |  |

3 h | 75% | |

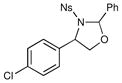

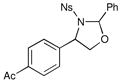

| 2 |  |

45 min | 52% | |

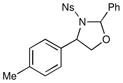

| 3 |  |

3 h | 54% | |

| 4 |  |

1 h | 70% | |

| 5 |  |

3 h | 75% | |

| 6 |  |

2.5 h | 65% | |

| 7 |  |

1 h | 84% | |

| 8 |  |

1.5 h | 59% | |

Conditions: 1 equiv of styrene, 1.5 equiv of 6, 5 mol% CuCl2, 5 mol% Bu4N+Cl−, CH2Cl2 (0.2 M in styrene), ambient temperature.