Abstract

This work investigates the effect of excipient particle size on compaction properties of brittle, plastic and viscoelastic materials with and without added lubricants. Sieve cuts of Microcrystalline cellulose (MCC), Starch and Dibasic calcium phosphate dihydrate were obtained by sieving, then samples were tested without lubrication or with added lubricant (0.5% Mg stearate mixed for either 5 or 30-min). Compacts were left overnight before testing. It was found that in the absence of lubricant, compact tensile strength (TS) was dependent on particle size only for starch. With Mg stearate, lubricant sensitivity shows a strong dependence on excipient particle size for both starch and MCC, where smaller particles are less affected by lubricant. Dibasic calcium phosphate dihydrate was not sensitive to lubricant even after 30 min mixing. This study highlights that in the absence of lubricant, initial particle size of excipients has no impact on compact strength not only for Dibasic calcium phosphate dihydrate (brittle), but also for MCC (plastic). On the other hand, TS is dependent on particle size both with or without added lubricant for starch (viscoelastic).

Key words: brittle, compaction, lubricant sensitivity, particle size, plastic

INTRODUCTION

Lubricants are commonly used in tablet formulations to reduce die wall friction during tablet compression and ejection. Among the different lubricants that are utilized in the pharmaceutical industry, magnesium stearate is the most commonly used (1,2). It is generally accepted that magnesium stearate forms an adsorbed lubricant film around host particles during mixing (2–4). This results in a decrease in solid–solid contact, including contact between tablet and die wall, hence, reduction in die wall friction. However, the aforementioned lubricant film also interferes with the bonding properties of the host particles by acting as a physical barrier (5–7). This causes a decrease in compact strength, especially with excessive lubricant amounts and/or prolonged mixing times (1,8,9). The effect of lubricant on compact strength depends on a number of factors such as its nature (8), concentration, mixing time (3,10), and specific surface area (2).

There are other properties of the excipients themselves that influence their sensitivity to lubricant, the most important of which is the mechanism by which the material undergoes deformation (2,11–14). Van der Watt studied the effect of particle size of microcrystalline cellulose on lubricant sensitivity and found that the effect of mixing time on tablet crushing strength decreased with increasing particle size (15). This effect was attributed to the larger shear forces in a mixer created by the larger particles. The effect of flow of the excipients on lubricant sensitivity was also studied using various types of starches (16). The authors found that less flowable starches were less affected by long mixing with magnesium stearate compared to more flowable starches. This is probably related to the higher shear forces that more flowable particles are able to exert on the lubricant particles, thus leading to more efficient particle coating by lubricants, leading to higher lubricant sensitivity with more flowable materials.

Zuurman et al. studied the effect of magnesium stearate on bonding and porosity expansion of tablets produced from materials with different consolidation properties (17). That work indicates that microcrystalline cellulose undergoes similar densification properties with added lubricant since the porosity under pressure for microcrystalline cellulose was similar with and without added lubricant (0.5% magnesium stearate). On the other hand, lubricated tablets were shown to have larger relaxation than those compressed with no added lubricant, indicating a reduction of inter-particle bonding as a result of the added lubricant.

In the literature, there are some reports that highlight the effect of particle size on lubricant sensitivity (15). However, there has been no systematic study of the effect of particle size on compaction properties in the presence or absence of lubricant. Moreover, no systematic studies are reported that examine more than one type of material (e.g., plastic, brittle and viscoelastic).

The primary goal of this work is to study the impact of lubricant on initial particle size sensitivity and vise versa. The impact of lubricant on initial particle size sensitivity and effect on compact strength was studied. This work also evaluates the impact of initial particle size on the extent to which a compact is affected by lubricant.

MATERIALS AND METHODS

Materials

Materials with different deformation mechanisms were selected for this work. Dibasic calcium phosphate dihydrate (Di-Tab, Rhodia Pharma Solutions, Inc., NJ) was used as an example of a brittle deforming material. Microcrystalline cellulose (MCC) was used as an example of a plastically deforming material. Three grades of MCC were utilized: Avicel PH-102, Avicel PH-302, and Avicel PH-200 (FMC Corp., Newark, DE). Starch 1500 (Colorcon Inc., Indianapolis, IN) was used as a viscoelastic material. The lubricant used in this work was magnesium stearate (vegetable grade, Mallinkcrodt Chemical Co., St. Louis, MO) at a level of 0.5%.

Methods

Different particle sizes of each excipient were obtained by sieving. For each excipient, coarse (180–250 μm) and fine (<74 μm) particles were studied in addition to the as-received excipient (only coarse and fine powders were used in the case of Avicel PH-102 and Avicel PH-302). Mg stearate was pre-sieved through a #25 mesh prior to mixing with powders. Powders (as-received, coarse, or fine) were mixed with Mg stearate using a V-shell blender for either 5 or 30 min (30 rpm). Compacts were prepared using powders (as-received, coarse, or fine) without/with added lubricant (5 or 30 min mixing). Compacts were made using an Instron Universal Testing System (5569) equipped with a 50 kN load cell. Compact weight was 400 ± 2 mg. The maximum compression force used was 7 kN for MCC compacts, and 20 kN for Di-Tab and starch compacts. For all compacts, cross head speed was 50 mm/min. The punches used were 10.3 mm flat faced punches. Punches and die were pre-lubricated using 5% Mg stearate suspension in methanol. Lubricant suspension was applied before each set of triplicates.

Compacts were allowed to relax for 24-h post compression. Compact dimensions (diameter and thickness) were determined using a dial caliper. Crushing strength was determined using the Instron Universal Testing System (5569; 1 kN load cell, 10 mm/min). Compact tensile strength (TS) was calculated using Eq. 1:

|

1 |

where, σ is tensile strength; H is crushing strength; D is the compact diameter; and t is the compact thickness. It is important to note that Eq. 1 can be used for calculating σ only if the compact fails diametrically (in this work, all compacts failed diametrically). “In die Heckel” analysis was conducted using Eq. 2:

|

2 |

where, SF is solid fraction, P is compression pressure; K is the slope of the linear portion of the “in die” Heckel plot; and A is the intercept of the linear portion when P is zero. The reciprocal of K, termed the apparent mean yield pressure, Py, provides a quantitative measure of the plasticity of the material. A lower Py indicates greater plasticity of a powder.

RESULTS AND DISCUSSION

Impact of Lubricant on Powder Particle Size Sensitivity

In this study, it is shown that for some materials the impact of initial powder particle size on compact tensile strength is influenced by whether a lubricant is used or not.

Microcrystalline Cellulose (MCC)

For plastically deforming materials, a decrease in initial particle size results in an increase in specific surface area and available inter-particulate bonding area. Hence, it is expected that a smaller initial particle size would result in an increase in compact strength. Even though Avicel PH-200 is predominantly a plastically deforming material (18), initial particle size of powders used to make the compacts has no impact on compact strength in the absence of lubricant (Table I, TS is 4.59, 4.63 and 4.39 MPa for compacts made using fine, as-received, and coarse powders, respectively). However, it is very clear that in the presence of lubricant (either 5 or 30 min mixing), compact strength is sensitive to initial particle size (Table I). For example, compact TS after 5-min mixing with magnesium stearate is 4.13 and 2.55 MPa for compacts made using fine and coarse powders, respectively. A similar behavior can be seen with two other grades of MCC (Avicel PH-102, and 302, Table I). In the absence of lubricant, compact strength is independent of initial particle size. However, in the presence of lubricant, compact strength is dependent on initial particle size (Table I). This fact is important and should be considered during formulation development since it is generally understood that there are variations in the properties of MCC obtained from different sources (19).

Table I.

Tensile Strength Data for Tablets Compressed with/without Lubricant for Different Mixing Times

| Sieve Fraction of Materials | Lubricant Mixing Time (min) | Tensile Strength (MPa) for Different Materials (Standard Deviation) | ||||

|---|---|---|---|---|---|---|

| Starch 1500 | Avicel PH200 | Avicel PH102 | Avicel PH302 | Di-Tab | ||

| <74 um | 0 (no lubricant) | 1.45 (0.07) | 4.59 (0.05) | 5.14 (0.14) | 4.42 (0.18) | 2.31 (0.52) |

| 5 | 1.21 (0.05) | 4.13 (0.06) | 4.80 (0.18) | 4.35 (0.01) | 2.32 (0.35) | |

| 30 | 0.94 (0.03) | 3.14 (0.08) | 4.01 (0.12) | 3.93 (0.10) | 2.25 (0.07) | |

| As received | 0 (no lubricant) | 0.66 (0.03) | 4.63 (0.09) | 2.17 (0.17) | ||

| 5 | 0.44 (0.02) | 2.85 (0.05) | 2.11 (0.03) | |||

| 30 | 0.18 (0.02) | 1.27 (0.04) | 2.01 (0.16) | |||

| 180–250 μm | 0 (no lubricant) | 0.42 (0.02) | 4.39 (0.05) | 5.26 (0.21) | 4.34 (0.09) | 1.93 (0.11) |

| 5 | Compact too weak to test | 2.55 (0.03) | 3.84 (0.09) | 3.50 (0.05) | 1.98 (0.11) | |

| 30 | Compact too weak to test | 1.30 (0.04) | 2.79 (0.03) | 2.69 (0.06) | 1.86 (0.10) | |

Starch

Unlike MCC, strength of starch compacts (a viscoelastic material) shows strong dependence on initial particle size with or without lubricant (Table I). In the absence of lubricant, strength of starch compacts is strongly dependent on initial particle size. The smaller the initial particle size, the stronger the compact. For example, in the absence of lubricant, tensile strength (TS) is 1.45 MPa and 0.42 MPa for compacts made using fine and coarse powders, respectively (i.e., ∼3.5 fold difference). However, the presence of lubricant increases starch compact tensile strength sensitivity to initial particle size. For the same amount of lubricant and the same mixing time, a larger fraction of the available bonding area is covered with lubricant for larger starch particles. This leads to an exacerbated effect of initial particle size on compact strength with added lubricant than that seen without added lubricant. This is listed in Table II. For example, in the absence of lubricant, compact TS using as-received powders is ∼one half of the compact TS using fine powders. However, compact TS using as-received powders is ∼one third or one fifth of compact TS using fine powders with either 5 or 30-min lubricant mixing, respectively. This observation is clearer for coarse starch particles, where in the presence of lubricant, compacts TS is diminished with coarse particles that are mixed with lubricant for either 5 or 30-min.

Table II.

Ratios of Starch Compact Tensile Strengths using Different Starch Sieve Cuts with/without Added Lubricant

| Sample | Ratio of Compact Tensile Strength for | |

|---|---|---|

| As Received Powder/Fine Powder | Coarse Powder/Fine Powder | |

| No lubricant | 0.46 | 0.29 |

| 5 min mixing | 0.36 | 0 |

| 30 min mixing | 0.19 | 0 |

Dibasic Calcium Phosphate Dihydrate

Dibasic calcium phosphate dihydrate compact TS slightly decreases with an increase in initial particle size (Table I). Tensile strength is 2.31 and 1.93 MPa for compacts made from fine and coarse powders, respectively (no added lubricant). However, this effect of initial particle size is not statistically significant (p > 0.05). A similar behavior is also seen in the presence of lubricant. This behavior is consistent with a material whose main deformation mechanism is brittle fracture. Initial particle size has little influence as particles fracture upon compression and new surfaces are generated (2).

Impact of Powder Particle Size on Lubricant Sensitivity

One approach that can be utilized to study material sensitivity to addition of lubricant is to calculate the Lubricant Sensitivity Ratio (LSR) (2), Eq. 3:

|

3 |

Where, H0 is compact crushing strength without lubricant, and H is compact crushing strength with added lubricant. The larger the LSR, the more sensitive the material is to lubricant addition. Making compacts of the same material from powders of different initial particle sizes makes it possible to study the effect of initial particle size on lubricant sensitivity.

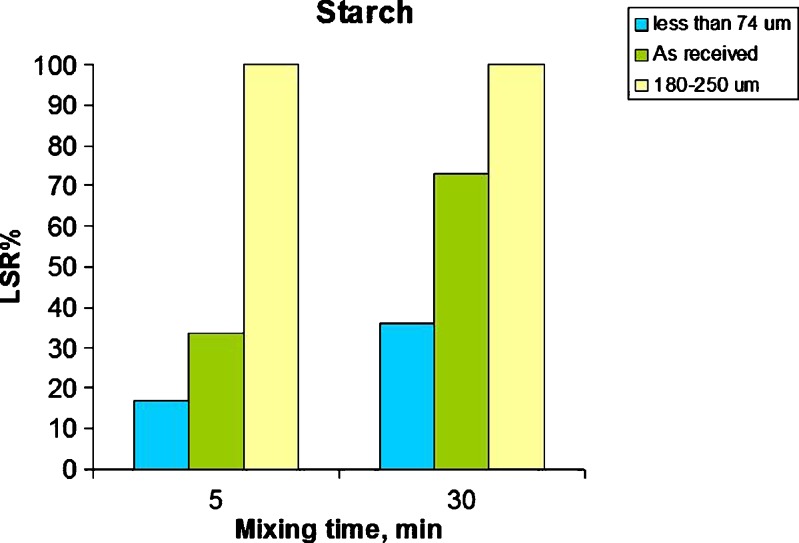

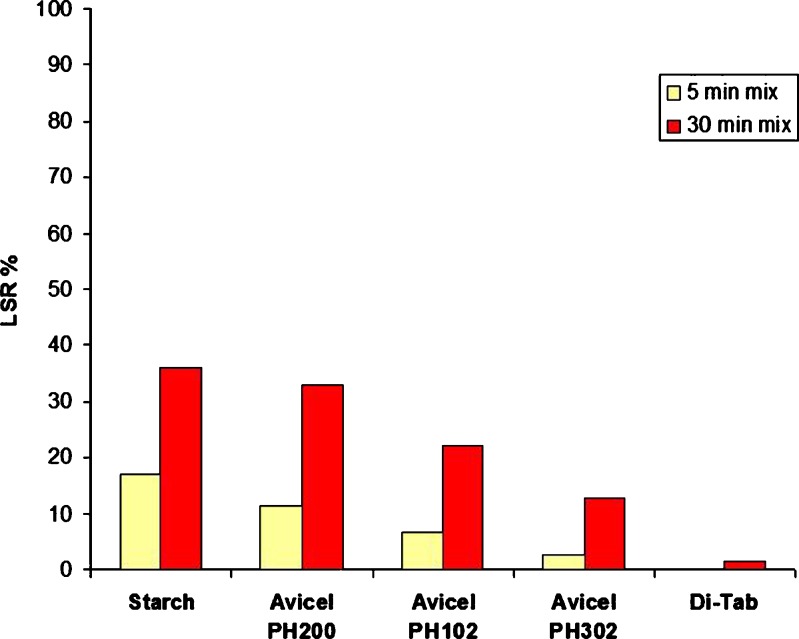

Starch

For any given particle size, TS of starch compacts decreases in the presence of lubricant and this decrease is more apparent with prolonged mixing time as expected (Table I). The decrease in TS with lubricant is greater when initial particle size of starch is larger. This is apparent from the sensitivity of LSR% to initial particle size (Fig. 1). The smaller the initial particle size, the smaller the LSR% (i.e., less sensitive to lubricants). For the same amount of lubricant and the same mixing time; the percent area covered with lubricant is less for a powder of smaller particle size.

Fig. 1.

Lubricant sensitivity ratio (different mixing times) for starch compacts made from powders of different particle sizes

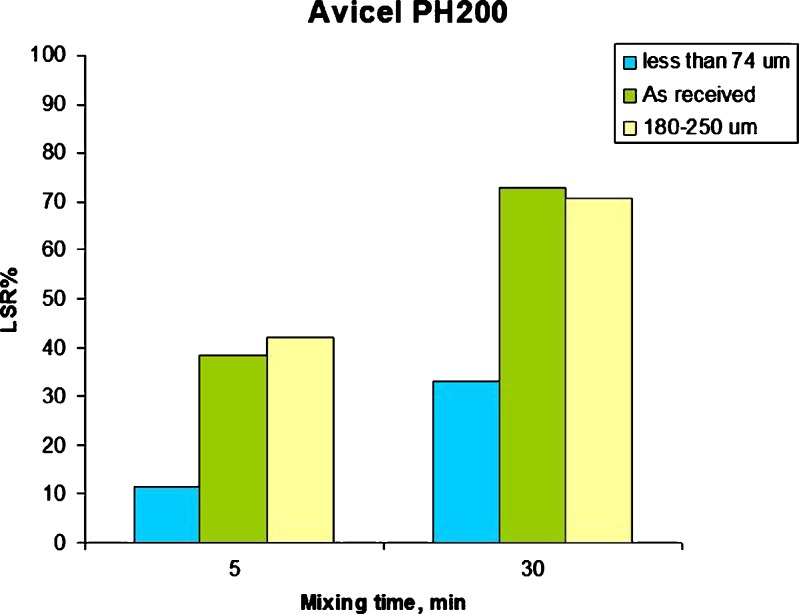

Microcrystalline Cellulose

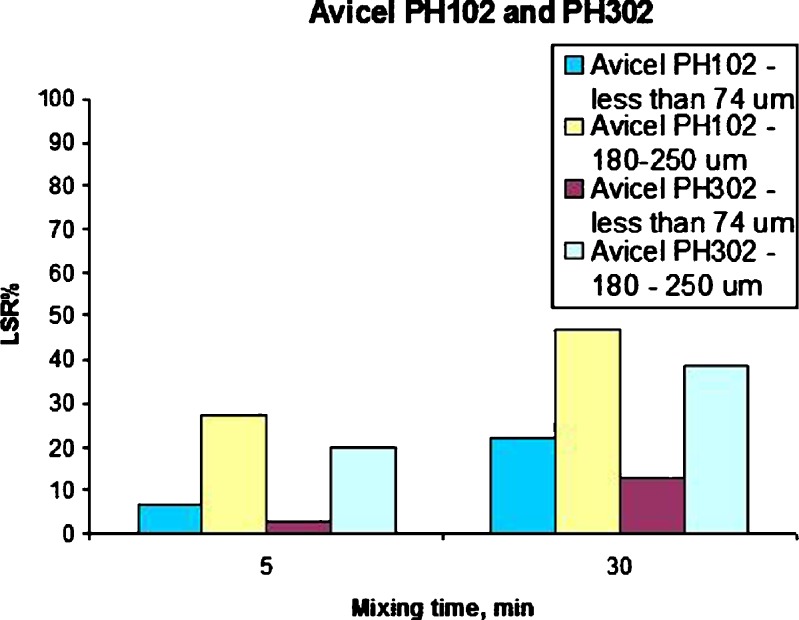

MCC is less sensitive to lubricant addition than starch. However, the effect of lubricant and the impact of initial particle size on lubricant sensitivity are similar to what is seen with starch. Irrespective of MCC grade, for any given particle size; TS decreases in the presence of lubricant and the decrease is more apparent with increased mixing time as expected for a plastically deforming material (Table I). The smaller the initial particle size, the smaller the LSR% (Figs. 2 and 3). This indicates that the smaller the initial particle size, the less sensitive MCC is to lubricant.

Fig. 2.

Lubricant sensitivity ratio (different mixing times) for Avicel PH-200 compacts made from powders of different particle sizes

Fig. 3.

Lubricant sensitivity ratio (different mixing times) for Avicel PH-102 and Avicel PH-302 compacts made from powders of different particle sizes

Dibasic Calcium Phosphate Dihydrate

Tensile strength of dibasic calcium phosphate dihydrate compacts is independent of lubricant addition and lubricant mixing time (Table I), and LSR% is small irrespective of initial particle size (<7%). This is characteristic of a material whose main deformation mechanism is brittle fracture. Upon compression, clean new surfaces are generated and lubricant film, if formed, is disrupted. This leads to decreased sensitivity to lubricant addition.

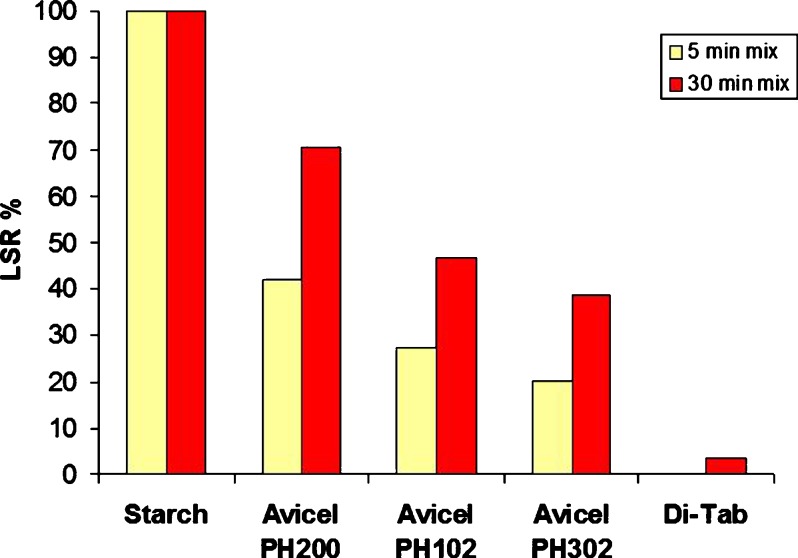

Impact of Deformation Mechanism on Lubricant Sensitivity

Lubricant sensitivity follows the same order irrespective of initial particle size (most to least sensitive): Starch 1500 > Avicel PH200 > Avicel PH102 > Avicel PH302 > Di-Tab. As expected, viscoelastic as well as plastic deforming materials are more sensitive to lubricant addition than brittle materials (Figs. 4 and 5). As seen in Figs. 1, 2 and 3, lubricant sensitivity may be mitigated by particle size reduction. It is interesting to note that the denser grade of MCC (Avicel PH-302) is less sensitive to lubricant addition than the less dense grades, Avicel PH-200; and Avicel PH-102. This could be related to porosity or specific surface area differences. However, this is speculative and needs to be further investigated.

Fig. 4.

Lubricant sensitivity ratio for excipients exhibiting different deformation mechanisms (coarse particles)

Fig. 5.

Lubricant sensitivity ratio for excipients exhibiting different deformation mechanisms (fine particles)

CONCLUSIONS

For a plastically deforming material (MCC), powder particle size impacts compact strength only with added lubricant (coarse MCC particles are more sensitive to lubricant). For a viscoelastic material (starch), powder particle size impacts compact strength with and without added lubricant (fine starch particles lead to stronger compacts and are less sensitive to lubricant). For a brittle material (dibasic calcium phosphate dihydrate), powder particle size has no significant impact on compact strength with and without added lubricant.

References

- 1.Moody G., Rubinstein M. H., FitzSimmons R. A. Tablet lubricants I. Theory and modes of action. Int. J. Pharm. 1981;9:75–80. doi: 10.1016/0378-5173(81)90001-6. [DOI] [Google Scholar]

- 2.Bolhuis G. K., Holzer A. W. Lubricant sensitivity. In: Alderborn G., Nystrom C., editors. Pharmaceutical Powder Compaction Technology. New York, NY, USA: Marcel Dekker; 1996. pp. 517–560. [Google Scholar]

- 3.Bolhuis G. K., Lerk C. F., Zijlstra H. T., De Boer A. H. Film formation by magnesium stearate during mixing and its effect on tabletting. Pharm. Weekbl. 1975;110:317–325. [Google Scholar]

- 4.Swaminathan V., Cobb J., Saracovan I. Measurement of the surface energy of lubricated pharmaceutical powders by inverse gas chromatography. Int. J. Pharm. 2006;312:158–165. doi: 10.1016/j.ijpharm.2006.01.014. [DOI] [PubMed] [Google Scholar]

- 5.De Boer A. H., Bolhuis G. K., Lerk C. F. Bonding characteristics by scanning electron microscopy of powders mixed with magnesium stearate. Powder Tech. 1978;20:75–82. doi: 10.1016/0032-5910(78)80011-4. [DOI] [Google Scholar]

- 6.Roblot-Treupel L., Puisieux F. Distribution of magnesium stearate on the surface of lubricated particles. Int. J. Pharm. 1986;31:131–136. doi: 10.1016/0378-5173(86)90222-X. [DOI] [Google Scholar]

- 7.Hussain M. S., York P., Timmins P., Humphrey P. Secondary ion mass spectrometry (SIMS) evaluation of magnesium stearate distribution and its effects on the physico-technical properties of sodium chloride tablets. Powder Tech. 1990;60:39–45. doi: 10.1016/0032-5910(90)80102-5. [DOI] [Google Scholar]

- 8.Lerk C. F., Bolhuis G. K., Smedema S. S. Interaction of lubricants and colloidal silica during mixing with excipients. Pharm. Acta Helv. 1977;52:33–39. [PubMed] [Google Scholar]

- 9.He X., Secreast P., Amidon G. Mechanistic study of the effect of roller compaction and lubricant on tablet mechanical strength. J. Pharm. Sci. 2007;5:1342–1355. doi: 10.1002/jps.20938. [DOI] [PubMed] [Google Scholar]

- 10.Mehrotra A., Llusa M., Faqih A., Levin M., Muzzio F. Influence of shear intensity and total shear on properties of blends and tablets of lactose and cellulose lubricated with magnesium stearate. Int. J. Pharm. 2007;336:284–291. doi: 10.1016/j.ijpharm.2006.12.013. [DOI] [PubMed] [Google Scholar]

- 11.Vromans H., Lerk C. F. Densification properties and compactibility of mixtures pharmaceutical excipients with and without magnesium stearate. Int. J. Pharm. 1988;46:183–192. doi: 10.1016/0378-5173(88)90076-2. [DOI] [Google Scholar]

- 12.Vromans H., Bolhuis G. K., Lerk C. F. Magnesium stearate susceptibility of directly compressible materials as an indication of fragmentation properties. Powder Tech. 1988;54:39–44. doi: 10.1016/0032-5910(88)80047-0. [DOI] [Google Scholar]

- 13.Eriksson M., Alderborn G. The effect of particle fragmentation and deformation on the interparticulate bond formation process during powder compaction. Pharm. Res. 1995;13:1031–1039. doi: 10.1023/A:1016214616042. [DOI] [PubMed] [Google Scholar]

- 14.Wurster D. E., Likitlersuang S., Chen Y. The influence of magnesium stearate on the Hiestand Tableting Indices and other related mechanical properties of maltodextrins. Pharm. Dev. Technol. 2005;10:461–466. doi: 10.1080/10837450500299693. [DOI] [PubMed] [Google Scholar]

- 15.Van Der Watt J. G. The effect of the particle size of microcrystalline cellulose on tablet properties in mixtures with magnesium stearate. Int. J. Pharm. 1987;36:51–54. doi: 10.1016/0378-5173(87)90235-3. [DOI] [Google Scholar]

- 16.Bos C. E., Bolhuis G. K., van Doorne H., Lerk C. F. Native starch in tablet formulations: properties on compaction. Pharm. Weekbl. Sci. Ed. 1987;9:274–282. doi: 10.1007/BF01953630. [DOI] [PubMed] [Google Scholar]

- 17.Zuurman K., Maarschalk V. V., Bolhuis G. K. Effect of magnesium stearate on bonding and porosity expansion of tablets produced from materials with different consolidation properties. Int. J. Pharm. 1999;179:107–115. doi: 10.1016/S0378-5173(98)00389-5. [DOI] [PubMed] [Google Scholar]

- 18.Aburub A., Buckner I., Mishra D. Utilization of compaction energetics for understanding particle deformation mechanism. Pharm. Dev. Technol. 2007;12:405–414. doi: 10.1080/10837450701366952. [DOI] [PubMed] [Google Scholar]

- 19.Whiteman M., Yarwood R. J. Variations in the properties of microcrystalline cellulose form different sources. Powder Tech. 1988;54:71–74. doi: 10.1016/0032-5910(88)80050-0. [DOI] [Google Scholar]