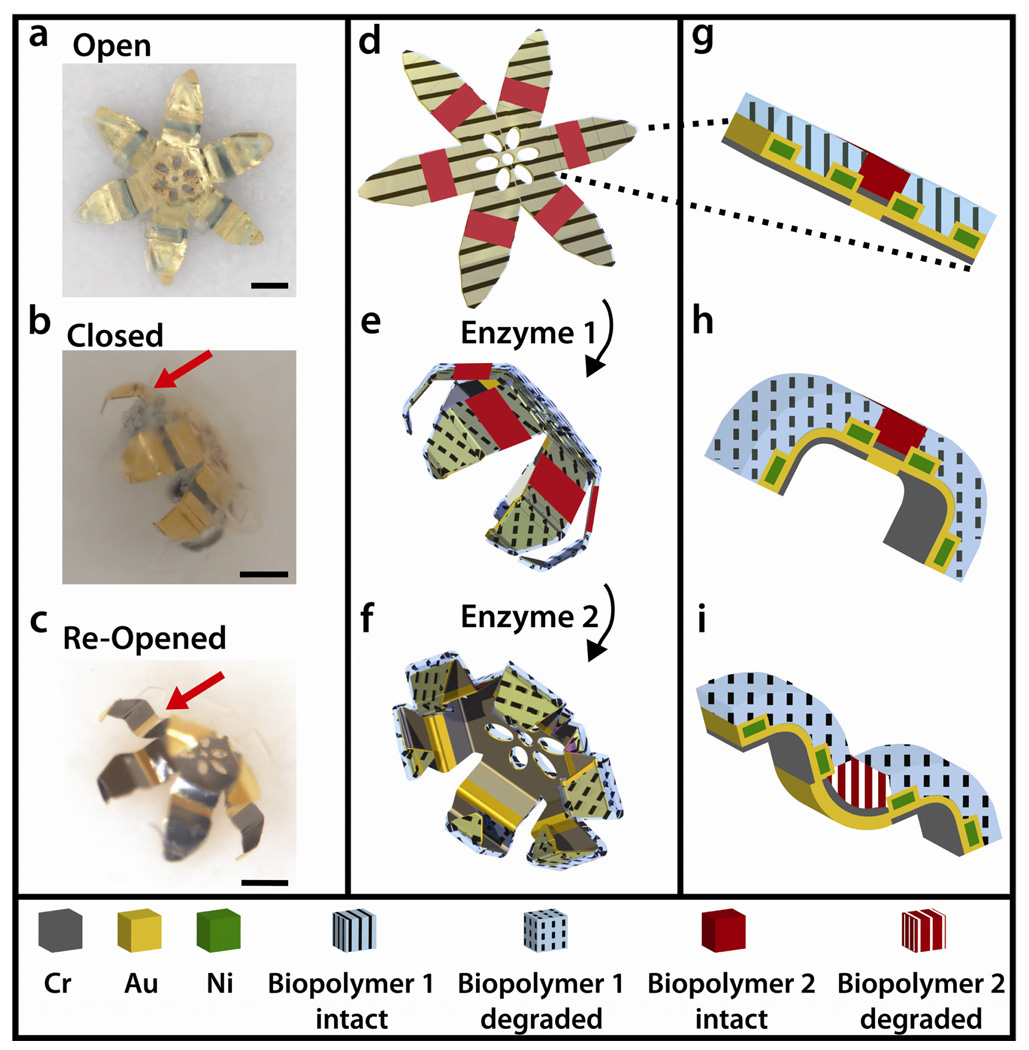

Figure 1.

Schematic of multilayered thin film gripper with integrated biopolymer layers that can close and re-open on exposure to enzymes. (a–c) Optical images of the grippers in the flat, closed, and re-opened states respectively. The red arrow indicates the second set of hinges. Scale bars represent 200 µm (a, b, c). (d–f) Schematic representations of the grippers in the three corresponding states above. (d) The gripper is held flat by the thick, crosslinked biopolymer (hatching). When this biopolymer is selectively degraded by enzyme 1 the modulus decreases and the gripper closes. (f) The second trigger, a rigid biopolymer insensitive to enzyme 1, is preventing a second set of hinges from actuating, keeping the gripper closed. (f) Subsequently this trigger can be actuated by enzyme 2 to re-open the gripper. (g–i) Cross section magnified view of a single hinge illustrating behavior of biopolymer trigger. (g) Both biopolymer layers are stiff, preventing all bending. (h) On degrading the biopolymer with enzyme 1, the second hinge remains flat. (i) The second polymer is degraded by enzyme 2 and this hinge bends in the opposite direction.