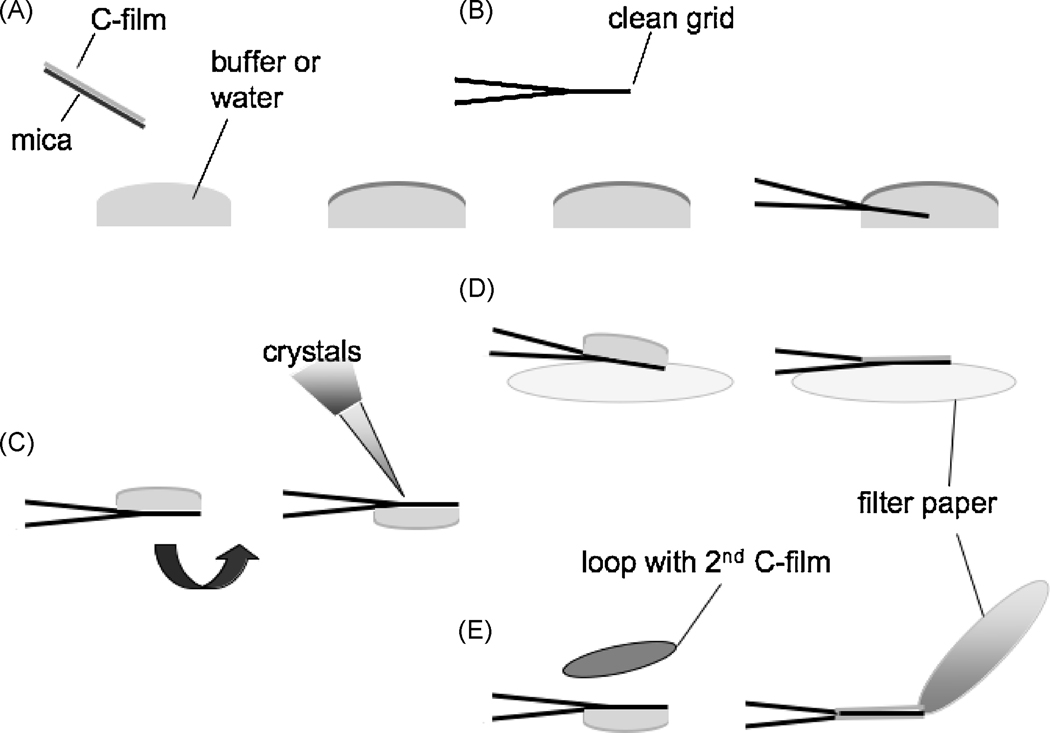

Figure 1.

Back-injection and carbon sandwich grid preparation involve the same initial steps. A, carbon film is floated off of a piece of mica. B, The carbon film is then picked up with a grid held by forceps. C, The grid is inverted by 180 ° so that the carbon film faces down, and the 2D crystal suspension is pipetted onto the grid. D, For the back-injection preparation, the grid is again inverted by 180 °. Thus the carbon faces up, and the grid is placed onto two pieces of filter paper for removal of the bulk of the liquid. After air-drying for 10–15 s to produce a thin layer of 2D crystal suspension, the grid is hand plunged into liquid nitrogen. E, The carbon sandwich preparation method requires a second carbon film to be picked up with a loop and placed over the grid. Excess liquid is removed from the side of the grid. After extensive air-drying, sometimes for minutes, the grid is hand-plunged into liquid nitrogen.