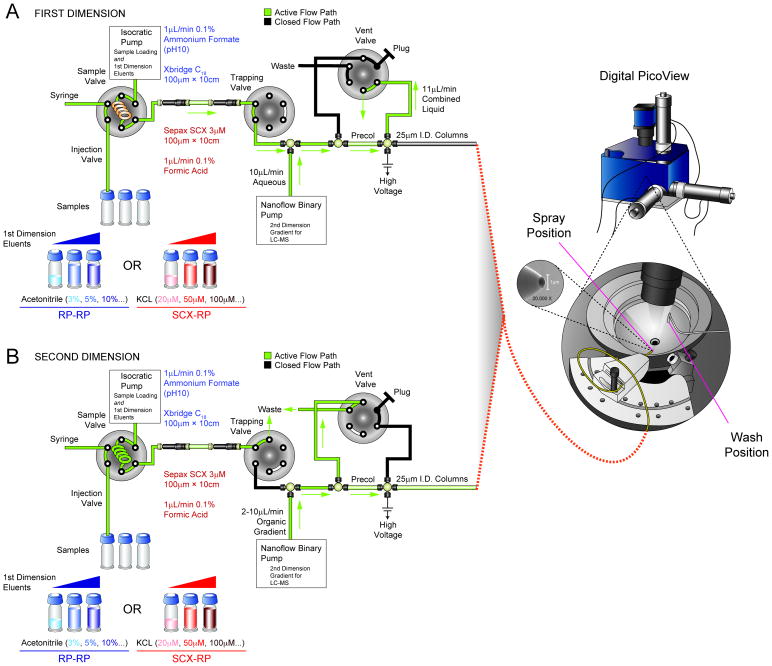

Figure 1.

Schematic diagram of automated, online nanoflow RP-RP platform. (A) The autosampler loads peptides and then is used to inject salt or organic eluents to generate first dimension SCX (red) or RP (blue) fractions, respectively. First dimension fractions are diluted (10×) and acidified with reversed phase A solvent (0.1% formic acid, 3% acetonitrile) introduced by an ultra-high pressure binary pump. An additional 6-port, 2-position valve provides a vented second dimension column configuration, and ensures efficient capture of peptides onto the precolumn. (B) The ultra-high pressure binary pump delivers an organic gradient to elute peptides from the second dimension column for MS/MS analysis. The vent valve generates an effluent split of ≈1000:1 to provide a stable column/ESI flow rate of ≈5 nL/min. Active solvent flow paths are highlighted in green. (right) A computer-controlled positioning platform (Digital PicoView) automatically moves the emitter tip beneath a wash station for sample loading in-between fractions.