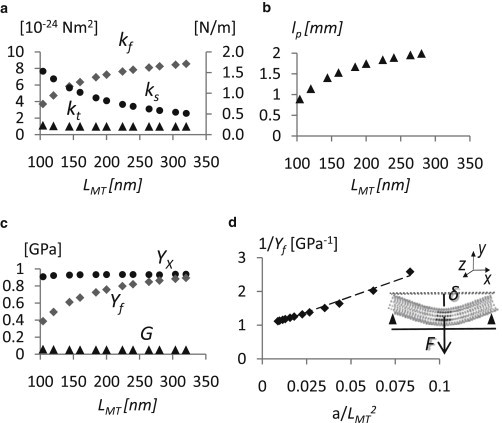

Figure 5.

(a) Data showing the relationship among the bending stiffness kf (diamonds), stretching stiffness ks (circles), torsion stiffness kt (triangles), and the MT length, LMT. The values kt remain constant with respect to LMT, while kf increases and ks decreases when MT length rises. (b) Relation between the persistence length lp (triangles) and LMT. A strong dependence of lp on the MT length is noticeable. (c) Bending modulus Yf (diamonds), stretching modulus Yx (circles), and shear modulus G (triangles), directly obtained by torsion stiffness versus LMT. The Yf values markedly increase with the MT length, approaching the value of Yx (∼1 GPa) for LMT at ∼300 nm. The G-value is constant and roughly equal to 0.05 GPa, i.e., two-orders-of-magnitude less than the Young's modulus Yx. (d) Inverse of the bending modulus 1/Yf, with respect to the constant a/LMT2, where a is equal to 12f(I/A) and f is a geometric factor equal to 1.38 in case of a hollow cylinder. The linear regression gives directly the value of Yx as the inverse of the y intercept of the fitting curve (Yx = 1.1 GPa), while G is the inverse of the slope of the curve (G = 0.05 GPa). A graphical description of the MT bending test is also reported; the MT is supported at the free ends and deflected, δ, by a concentrated force, F, acting in the middle.