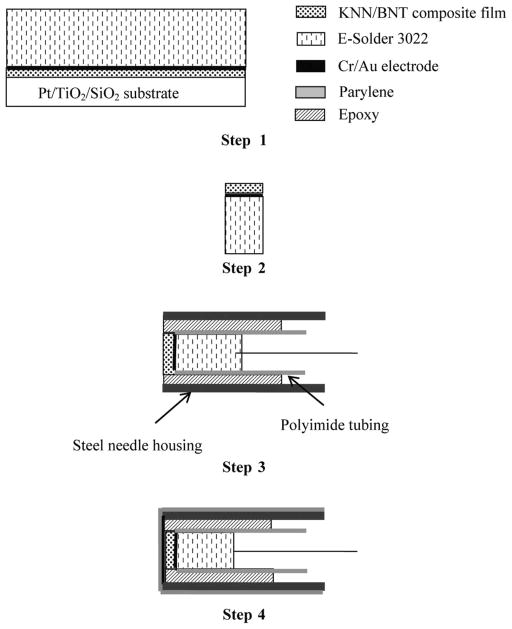

Fig. 1.

Fabrication process for the needle transducer. Step 1: A Cr/Au electrode was sputtered on the KNN/BNT composite film and a conductive epoxy (E-Solder 3022) was cast on the electrode side as the backing. Step 2: The sample was diced into 0.25 × 0.25 mm posts and the substrate was removed by dipping in KOH solution at 80°C. Step 3: A lead wire was connected to the backing layer using conductive epoxy. The element was inserted into a polyimide tube and was then fixed into the housing of a steel needle using epoxy. Step 4: A Cr/Au electrode was sputtered across the KNN/BNT composite element and needle housing to form the ground plane connection. Vapor-deposited parylene (1.5 μm thick) was used to coat the aperture and the needle housing. The finished transducer was housed in the SMA connector as shown in Fig. 2.