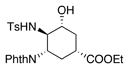

Table 3.

Attempted elimination conditions.

| ||

|---|---|---|

| Entry | Conditions | Notes |

| 1 | 2 equiv. LDA, THF, −78 °C | Decomposition to baseline by TLC |

| 2 | 1 equiv. KOtBu, THF, 0 –40 °C | No desired product |

| 3 | 5 equiv. KOtBu, THF, rt | Messy, t-BuO− attacked ester |

| 4 | 1 eq LIDAKOR[a], hexanes, 0 °C-rt | NR (substrate not dissolving) |

| 5 | 1 eq LIDAKOR, THF, −78 °C | Decomposition to baseline by TLC |

| 6 | 1.5 eq DBU, toluene, reflux | NR |

| 7 | 50 mol% In(OTf)3, 2,6-di-tert-butylpyridine, THF, 50 °C | NR |

| 8 | 20 mol% In(OTf)3, proton-sponge, THF, reflux | No desired reaction. In(OTf)3 reacted with proton-sponge to form insoluble solids in the reaction. |

| 9 | Ho(OTf)3, 2,6-di-tert-butylpyridine, chlorobenzen, 100 °C | NR, recovered starting material |

| 10 | Al(OTf)3, 2,6-di-tert-butylpyridine, DCM, 0 °C-rt | 100% NMR yield[c] of 24 |

| 11 | In(OTf)3, 2,6-di-tert-butylpyridine, chlorobenzene, 100 °C | NMR yields: 23% 23, 30% 24, 25 30% |

| 12 | In(OTf)3, 2,6-di-tert-butylpyridine, chlorobenzene, 3Å MS, 100 °C | NR, recovered starting material |

LIDAKOR=LDA + tBuOK.

NR = no reaction

NMR yields were determined by using 1,3,5-trimethoxybenzene as an internal standard.