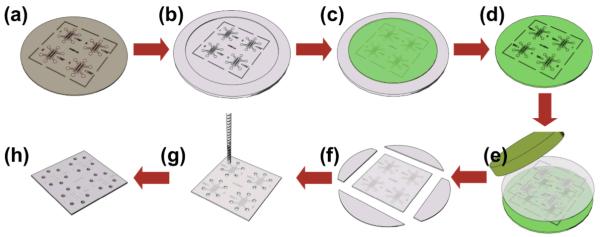

Fig. 1.

Hot embossing generated the devices. Patterned SU8 photoresist on a silicon wafer (a) served as a mold to create a negative replica in PDMS (b) to permit pouring and curing of epoxy (c) to create the durable epoxy master mold (d). The master mold formed the microfluidic features in the COC plate under load and elevated temperature through hot embossing (e). The resulting embossed COC plate was trimmed (f), drilled for fluid connections (g), then sealed with a thin COC laminate layer to complete the array of finished devices (h)