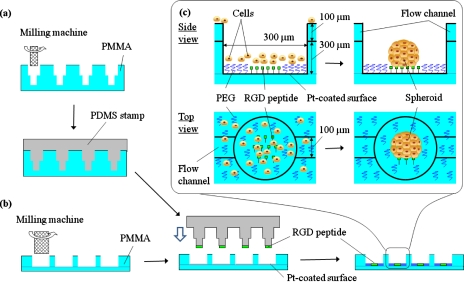

Figure 1.

Schematics of the fabrication of a SM chip with microchannels. (a) Preparation of a stamp for microcontact printing. Concave wells of 100 μm head diameter were constructed in a PMMA plate, with which a PDMS stamp was molded. (b) Modification of microwells for cell culture. Microwells 300 μm in diameter and 400 μm in height were connected to channels 100 μm wide and 100 μm deep. The entire surface of the chip, including microwells, was coated with a thin platinum layer. The PDMS stamp was inked with 1 mM RGD peptide and microscopically contacted with the center of the bottom faces of the microwells to create cell adhesion regions. The chip was immersed in 5 mM PEG-SH in ethanol solution to obtain a cell nonadhesion region around the RGD peptide stamped regions. (c) Spheroid formation in a microwell.