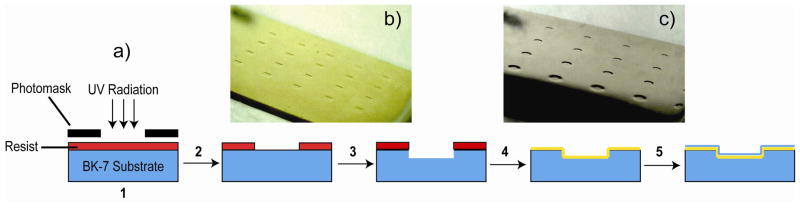

Figure 1.

a) Fabrication procedure for the etched glass array SPRi substrate. 1 BK7 glass slides were patterned using standard photolithography with a photomask containing 800 μm circles and squares with 1.6 mm center-to-center spacing; 2 The patterned substrate was developed in the exposed UV irradiated areas; 3 BOE etching to different micrometer level etch depths completed and thereafter photoresist is removed with acetone; 4 Deposition of 2 nm chromium adhesion layer, followed by a 51 ± 2 nm gold layer via e-beam evaporation; 5 For the CT/GM1 surface sensitivity study, deposition of 3–6 nm silicon dioxide (light blue) by plasma enhanced chemical vapor deposition (PECVD) at 300 ºC. b) Sample optical image of the square gold coated glass etched array (etched well: 800 μm). c) Sample optical image of the circular gold coated glass etched array (etched well: 800 μm).