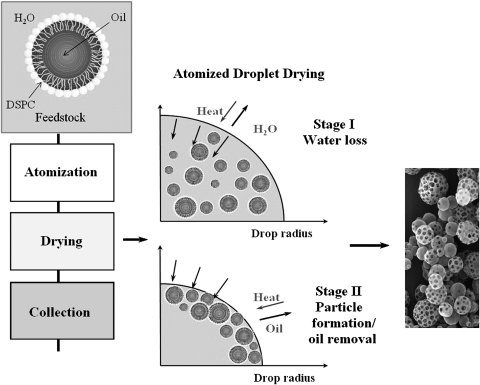

FIG. 1.

Schematic of the PulmoSphere™ manufacturing process. An emulsion-based feedstock is prepared by high-pressure homogenization. The emulsion consists of oil droplets (Perflubron) dispersed in a continuous water phase. The oil droplets are stabilized by a monolayer of a phospholipid (distearoylphosphatidylcholine). The tobramycin drug substance and calcium chloride excipient are dissolved in the continuous phase of the emulsion. The feedstock is atomized with a twin fluid nozzle into a spray dryer. As the atomized droplets containing dispersed emulsion droplets are dried, the slow diffusing emulsion droplets are concentrated at the droplet interface. As the drying continues, a shell is formed at the surface of the atomized droplet. Eventually, the Perflubron evaporates leaving behind pores in the particle shell. The resulting dry powder comprising porous particles is collected from the airstream with a cyclone separator.