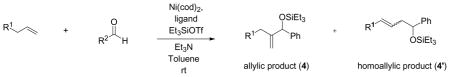

Table 12.

Coupling of Oxygen-Containing Alkenes with Aldehydes a

| |||||||

|---|---|---|---|---|---|---|---|

| entry | R1 (alkene) | R2 (aldehyde) | ligand | major product | yield (%) b | ratio (4:4′) b | ratio (E:Z) c |

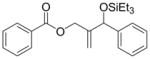

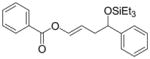

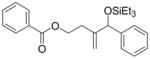

| 1 |

|

Ph | Cy2PhP |

4d |

<5 | n.d. | - |

| (EtO)Ph2P |

4d′ |

<5 | n.d. | n.d. | |||

| 2 e |

|

Ph | Cy2PhP |

4e |

21 | n.d. | - |

| (EtO)Ph2P |

4e′ |

<5 | n.d. | n.d. | |||

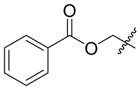

| 3 |

|

o-anisyl | Cy2PhP |

4f |

44 d | 73:27 | - |

| 4 e |

|

o-anisyl | (EtO)Ph2P |

4g |

66 | 7:93 | 50:50 |

Standard procedure: To a solution of Ni(cod)2 (0.1 mmol) and ligand (0.2 mmol) in toluene (2.5 mL) at 23 °C under Ar were added the alkene (2.5 mmol), triethylamine (3.0 mmol), the aldehyde (0.5 mmol), and Et3SiOTf (0.875 mmol). The mixture was stirred 48 h at room temperature and purified by chromatography (SiO2).

Determined by 1H NMR of the crude reaction mixture using DMF as a standard.

The ratio was determined by 1H NMR of the mixture of E and Z homoallylic alcohols after the silyl group of the coupling product was removed by TBAF.

Isolated yield.

1.5 mmol alkene was used.