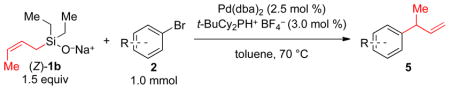

Table 3.

Preparative Palladium-Catalyzed Allylations of Substituted Aromatic Bromides Using (Z)-1b and 3a

| |||

|---|---|---|---|

| entry | product | yield,b % | γ/αc |

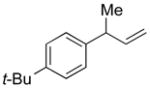

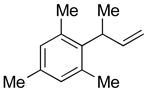

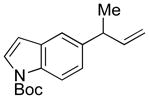

| 1 |

5a |

90 | >99:1 |

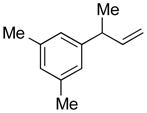

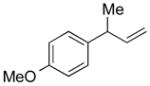

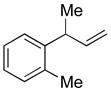

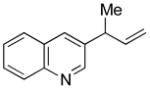

| 2 |

5b |

92 | >99:1 |

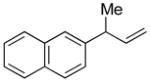

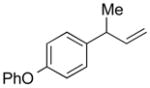

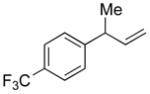

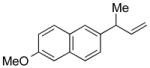

| 3 |

5c |

89 | >99:1 |

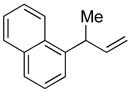

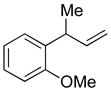

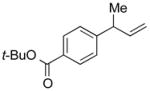

| 4 |

5d |

94 | >99:1 |

| 5 |

5e |

85 | >99:1 |

| 6 |

5f |

84 | >99:1 |

| 7 |

5g

|

85 | >99:1 |

| 8 |

5h

|

73 | >99:1 |

| 9 |

5i

|

74 | >99:1 |

| 10d |

5j |

82 | >99:1 |

| 11 |

5k |

91 | >99:1 |

| 12 |

5l |

88 | 99:1e |

| 13d,f |

5m |

82 | 25:1 |

| 14 |

5n |

91 | >99:1 |

Reactions performed on 1.0 mmol scale.

Yield of isolated, purified product.

GC peak area ratio of crude reaction mixture.

5% Pd(dba)2 and 6% t-BuCy2PH+BF4− used.

Determined by 1H NMR analysis (>100:1 S/N).

90 °C reaction temperature used.