Table 3.

| |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Comp | Step a | Step b | Step c | Step d | |||||

| 28–31 | R | Time (h) | % Yield | Time (min) | % Yield | Time (h) | % Yield | Time (h) | % Yield |

|

(min)

| |||||||||

| a | Me | 26 | 91 | 15 | 99c | 96 | 77 | 7 | 64e |

| b | Pr | 5 | 98d | 15 | 99c | 72 | 51 | 5 | 75 |

| c | n-hexyl | 14 | 97 | 15 | 77 | 72 | 39d | 12 | 62 |

| d | Bn | 6 | 98d | 15 | 75d | 64 | 63d | 5.5 | 84d |

| e | (CH2)2Ph | 10 | 88d | 15 | 73 | 60 | 49 | 4.5 | 64d |

| f | allyl | 10 | 87 | 15 | 58 | 66 | 54 | 5 | 55 |

| g | 3-(OPh)Bn | 24 | 50 | 15 | 70 | 70 | 59 | 7 | 60 |

| h | 4-(CF3)Bn | 22 | 98 | 15 | 62 | 96 | 56 | 7 | 81 |

| i | 4-(OCF3)Bn | 22 | 86 | 15 | 72d | 96 | 53d | 19 | 70 |

|

| |||||||||

| Average | 15 | 88 | 15 | 70f | 77 | 56 | 8 | 68 | |

| Range | 5–26 | 50–98 | 15 | 58–77f | 60–96 | 39–77 | 4.5–19 | 55–84 | |

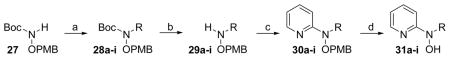

Reagents and conditions: (a) NaH, RX (alkyl halide), DMF, 0 °C–rt. (b) TFA, CH2Cl2, rt; then aq. NaHCO3. (c) 2-bromopyridine, Pd2(dba)3, (±) BINAP, NaOtBu, toluene, 70 °C. (d) TFA, Et3SiH, CH2Cl2, rt; then aq. NaHCO3.

Yields are based on isolated, purified, and characterized material unless otherwise stated and optimal reaction time listed if reactions were replicated.

Crude yield.

Average of two yields.

Average of three yields.

Calculated for purified products only.