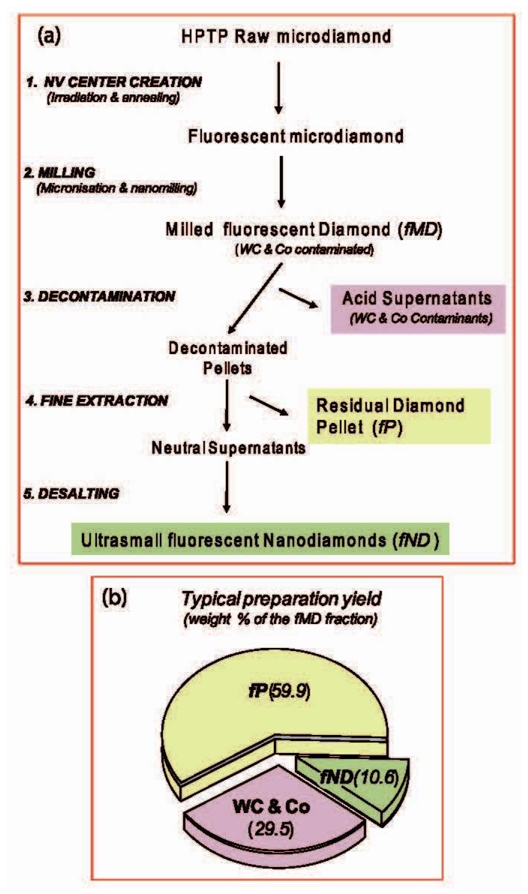

Figure 1.

Flow chart for fluorescent ultrasmall nanodiamond (fND) preparation. (a) NV creation is obtained by 10 MeV electron irradiation of raw HPHT microdiamond followed by annealing at 800° C under vacuum. Milling of the fluorescent microdiamond is performed in two steps, micronization and nanomilling. Decontamination includes a hot HF/HNO3 attack followed by a series of centrifugation steps. The first pellet is resuspended in a small MQW volume. The second pellet is resuspended in a large MQW volume and NH4OH neutralized. Supernatants obtained by three subsequent centrifugations are pooled and desalted by ultrafiltration, (b) Mass distribution of the metal-contaminated diamond (fMD) fractions expressed in dry weight per cent. The WC + Co fraction mass was obtained by subtracting the pellet (fP) and fND mass from the fMD mass.