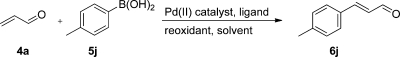

Table 1. Optimization of the Reaction Conditions with Acroleina.

| entry | catalytic mixb | solvent | time | temp | GC–MS responsec | ratio 4a:5j |

|---|---|---|---|---|---|---|

| 1 | 7a/8a/9 | DMF | 24 h | rt | 80 | 1:2 |

| 2 | 7a/8a/9 | MeCN | 24 h | rt | 85 | 1:2 |

| 3 | 7a/8a/9 | ethanol | 24 h | rt | <1 | 1:2 |

| 4 | 7b/8a/9 | MeCN | 24 h | rt | 77 | 1:2 |

| 5 | 7a/8b/9 | MeCN | 24 h | rt | <1 | 1:2 |

| 6 | 7a/8a/air | MeCN | 24 h | rt | 81 | 1:2 |

| 7 | 7a/8a/9 | MeCN | 0.5 h | 100 °C | 65 | 1:2 |

| 8 | 7a/8a/9 | MeCN | 24 h | rt | 66 | 2:1 |

| 9 | 7a/8a/9 | MeCN | 24 h | rt | 60 | 5:1 |

All reactions were carried out with acrolein (4a) and p-tolylboronic acid (5j), on a 1 mmol scale with Pd(II) catalyst (0.02 mmol), ligand (0.024 mmol), reoxidant (p-bzq, 1 mmol or air), and solvent (2 mL) for the time and temperature indicated.

Combination of Pd(II) catalyst, ligand, and reoxidant, consisting of either Pd(OAc)2 (7a) or Pd(OCOCF3)2 (7b), dmphen (8a) or dppp (8b), and p-bzq (9) or air as indicated.

Naphthalene was added to each reaction and the GC–MS response was calculated according to (peak area of 6j/naphthalene peak area) × (cnaphthalene/c4a or 5j) × 100. The amount of homocoupled product was <5%. No double arylated Heck product was detected.