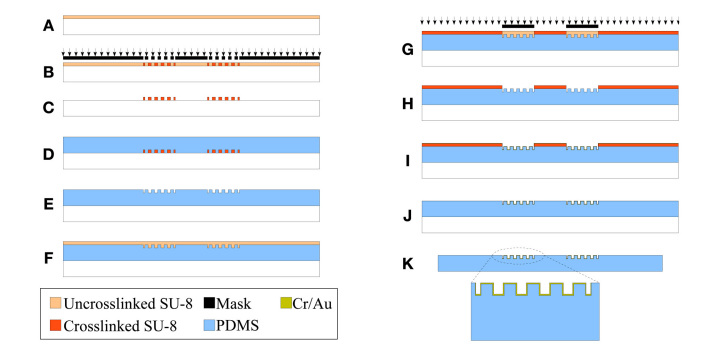

Figure 2.

Complete fabrication process flow for flexible 3-D electrodes. (A) Spin the SU-8 layer onto a cleaned glass substrate for use as the soft lithography mold; (B) bake and expose the SU-8 layer with the desired mask pattern for the pillar array; (C) bake and develop the uncross-linked SU-8 to obtain the desired mold pattern; (D) after hard baking the mold, pour the PDMS mixture onto the mold and cure at an elevated temperature; (E) transfer the molded PDMS layer (with the pillar structures) onto another glass substrate; (F) spin the SU-8 layer for the metallization shadow mask; (G) bake and expose the SU-8 layer to pattern openings for the metal deposition; (H) bake and develop away the uncross-linked SU-8 to realize the SU-8 shadow mask; (I) deposit Au after Cr adhesion layer; (J) mechanically peel off the SU-8 shadow mask to realize the desired metal pattern; and (K) remove the PDMS-based glucose sensor from the glass substrate and electroplate the reference electrode with Ag followed by chloridation to realize the Ag/AgCl reference electrode.