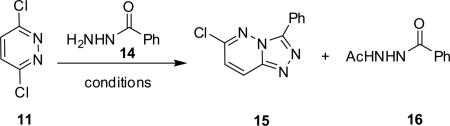

Table 1.

Optimization of MAOS conditions to produce 15

| ||||

|---|---|---|---|---|

| Entry | T (°C) | Solvent | Time (min) | 15:16a |

| 1 | 140 | HOAc | 10 | 42:58 |

| 2 | 160 | HOAc | 10 | 28:72 |

| 3 | 180 | HOAc | 10 | 24:76 |

| 4 | 200 | HOAc | 10 | 13:87 |

| 5 | 150 | 50% HOAc/EtOH | 10 | 78:22 |

| 6 | 170 | 50% HOAc/EtOH | 10 | 64:36 |

| 7 | 150 | 10% HOAc/EtOH | 10 | 79:21 |

| 8 | 170 | 10% HOAc/EtOH | 10 | 74:26 |

| 9 | 150 | 5% HOAc/EtOH | 10 | 85:15 |

| 10 | 170 | 5% HOAc/EtOH | 10 | 77:23 |

| 11 | 135 | 5% HOAc/EtOH | 20 | 80:20 |

| 12 | 135 | EtOHb | 10 | – |

| 13 | 150 | 5% HCI/EtOHc | 10 | 100:0 |

Ratio determined by analytical LC-MS and 1H NMR; conversion >95%.

No product formed without acid catalysis.

5% 4 N HCl/dioxane.