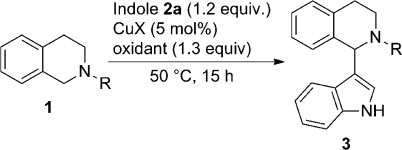

Table 1. Optimization of the Catalyst System and Choice of PG.

| entry | R | cat. | oxidant | yield (%) |

|---|---|---|---|---|

| 1 | Ac (1a) | Cu(NO3)2c | tBHP | 54 |

| 2 | Ac (1a) | CuBr | tBHP | 47 |

| 3 | Piv (1b) | Cu(NO3)2c | tBHP | 26 |

| 4 | Piv (1b) | CuBr | tBHP | 21 |

| 5 | Bn (1c) | Cu(NO3)2c | tBHP | 60 |

| 6 | Bn (1c) | CuBr | tBHP | 36 |

| 7 | Bz (1d) | Cu(NO3)2c | tBHP | 40 |

| 8 | Bz (1d) | CuBr | tBHP | 10 |

| 9 | CBz (1e) | Cu(NO3)2c | tBHP | 60 |

| 10 | CBz (1e) | CuBr | tBHP | 41 |

| 11 | Tos (1f) | Cu(NO3)2c | tBHP | traces |

| 12 | Tos (1f) | CuBr | tBHP | traces |

| 13 | 2-Py (1g) | Cu(NO3)2c | tBHP | 61 |

| 14 | 2-Py (1g) | CuBr | tBHP | 44 |

| 15 | Boc (1h) | Cu(NO3)2c | tBHP | 79 |

| 16 | Boc (1h) | CuBr | tBHP | 72 |

| 17 | Boc (1h) | CuCN | tBHP | (65) |

| 18 | Boc (1h) | Cu(OAc)2 | tBHP | (74) |

| 19 | Boc (1h) | CuI | tBHP | (61) |

| 20 | Boc (1h) | CuBr | tBHP | (73) |

| 21 | Boc (1h) | CuCl | tBHP | (74) |

| 22 | Boc (1h) | CuF2 | tBHP | (76) |

| 23 | Boc (1h) | CuCl | nca | |

| 24 | Boc (1h) | CuCl2 | nca | |

| 25 | Boc (1h) | Cu(NO3)2c | H2O2 (30%) | tracesb |

| 26 | Boc (1h) | Cu(NO3)2c | mCPBA | tracesb |

| 27 | Boc (1h) | Cu(NO3)2c | DBPO | tracesb |

| 28 | Boc (1h) | tBHP | nc |

nc = no conversion.

1 equiv of catalyst was employed.

Monitoring according to GC/MS, conversion in parentheses according to HPLC.

Cu(NO3)2·3H2O employed.