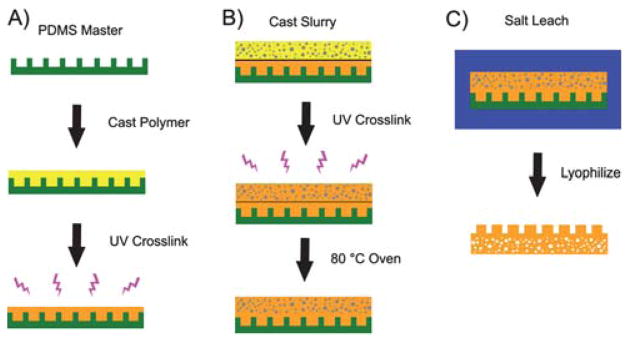

Fig. 2.

(A) A schematic representation of the microchannel fabrication process: pre-POMaC, PI, and 1,4-dioxane are mixed together and cast over the PDMS master. Following the removal of air trapped in the channels, the pre-POMaC is exposed to UV irradiation to form PPOMaC channels. (B) A schematic representation of the scaffold addition process: pre-POMaC, PI, salt, and 1,4-dioxane are mixed together to create a thick slurry and cast over the PPOMaC channels. The slurry is then exposed to UV irradiation, and cured at 80 °C to fuse the scaffold to the microchannels. (C) Following post-polymerization, the entire scaffold/microchannel construct is suspended in deionized water to leach out the salt from the scaffold. The construct is then peeled away from the PDMS master and lyophilized to remove any water. The resulting scaffold is soft, flexible, and biodegradable with microchannels that can be used for cellular alignment (schematic not drawn to scale).