Table 2.

Substrate Scope for C–H Functionalization

| entry | substrate | product | yieldb |

|---|---|---|---|

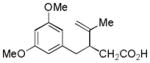

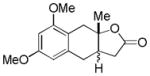

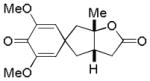

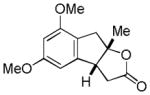

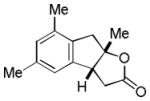

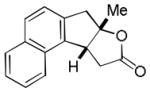

| 1 |

5 |

6 |

92%c |

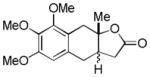

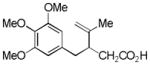

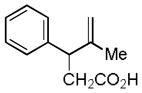

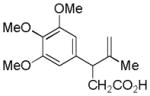

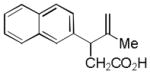

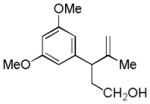

| 2 |

7 |

8 |

68%d,e |

8a |

20% | ||

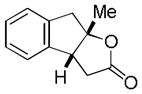

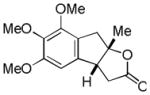

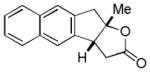

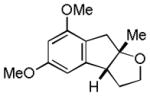

| 3 |

9 |

10 |

60% |

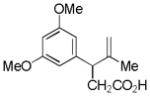

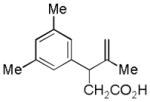

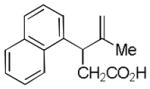

| 4 |

11 |

12 |

61% |

| 5 |

13 |

14 |

53% |

| 6 |

15 |

16 |

57% |

| 7 |

17 |

18 |

56% |

| 8 |

19 |

20 |

51% |

| 9 |

21 |

22 |

46% |

Reaction Conditions: Pd(OAc)2 (10 mol %), PhI(OAc)2 (2.0 equiv), CH3CN, rt, 12 h;

Isolated yield (%) after purification by chromatography on SiO2;

dr 1.75:1;

dr 1.3:1;

see ref 21