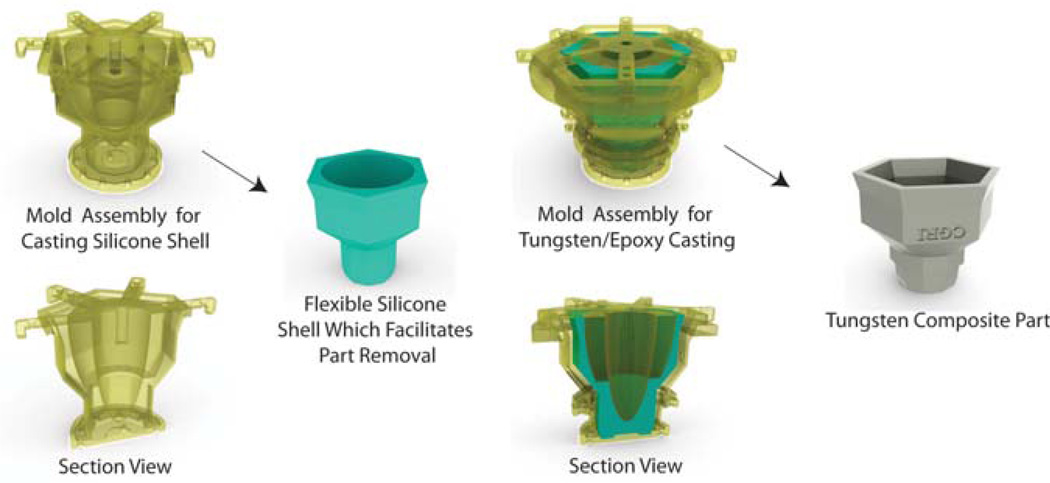

Figure 3.

A non-destructive approach to cold casting high-density tungsten composites: an RTV silicone shell is cast using a 3D-printed mold assembly. This part serves as a .exible inner section of the mold to facilitate part removal after curing. This inner section is combined with a hard-plastic, outer shell (multiple pieces fastened together, see Figure 8) and a tungsten powder/epoxy mixture is poured into the gap separating the two regions (see Figure 4). Prior to the pour, the outer shell is coated with a thin layer of mold release agent. After the epoxy is cured, the mold assembly is dismantled revealing a part having a density ~9 g/cm3. With this technique, duplicate parts can be made from a single mold assembly.