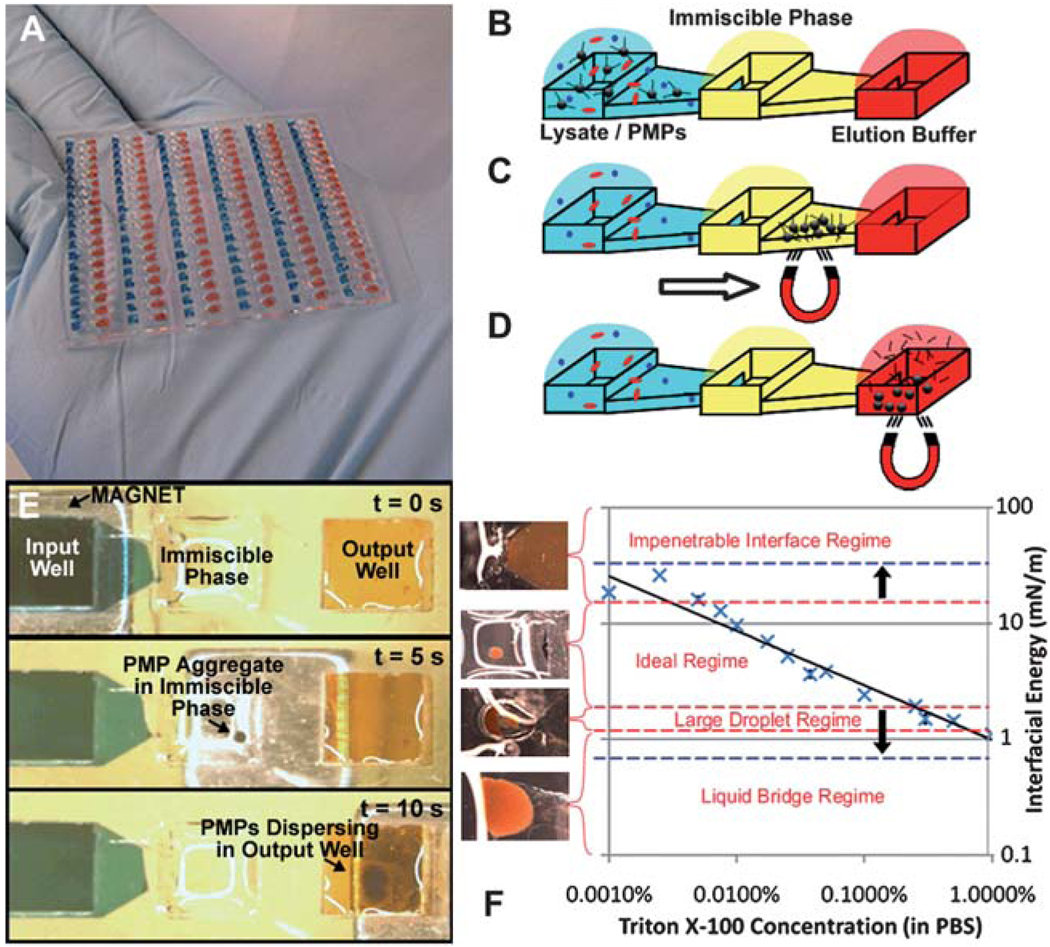

Fig. 2.

IFAST device design and operation. Large arrays of devices, such as the 114 device array shown in (A), can be operated in parallel using arrays of magnetic strips. The IFAST platform consists of three wells connected in series by microchannels. The central well is loaded with an immiscible oil phase to separate cell lysate containing NA-binding magnetic particles from nuclease-free elution buffer (B). A magnet is utilized to draw NA-bound particles through the immiscible phase (C) and into elution buffer (D). The total time to operate actual device is only 10 seconds (E). Increasing the concentration of a detergent (Triton X-100) reduces the interfacial energy with the oil phase (Chill-Out Liquid Wax), promoting carryover of liquid across the immiscible phase barrier (F). The various regimes of PMP transfer are defined by the red dashed lines and photographs of representative traverses are given in the graph, with an interfacial energy of −3 to 15 mN m−1 resulting in ideal transfer of PMPs. By reducing the surface energy between the oil and the device surface, the ideal regime can be expanded, as defined by the blue dashed lines, to encompass the entire tested range of detergent concentrations.