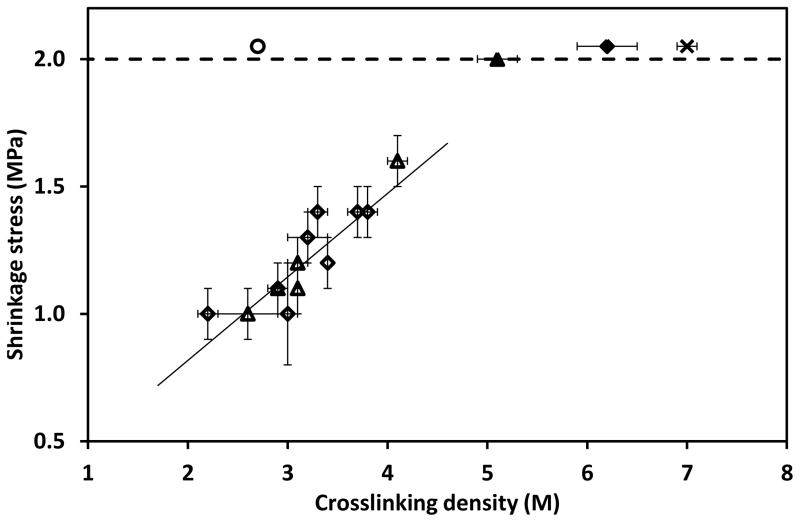

Figure 7.

Shrinkage stress versus crosslinking density of PETMP-HDY-EBPADMA systems. PETMP-HDY-EBPADMA systems with stoichiometric thiol to yne ratio with varying methacrylate amount (functional group ratio of thiol:yne:methacrylate was 2:1:x) and off stoichiometric thiol to yne ratios with fixed methacrylate content (functional group ratio of thiol:yne:methacrylate was x:y:2.7 listed in Table 1) (◇), PETMP-HDY-EBPADA systems with stoichiometric thiol to yne ratio with varying acrylate amount (functional group ratio of thiol:yne:acrylate was 2:1:x) (△), EBPADMA (◆), EBPADA (▲), PETMP-HDY (2:1) (✗) and PETMP-HDE-EBPADMA (1.5:1.5:2.7) (○). All resins were initiated with 1 wt% Irgacure 184 and were cured by 365nm light at 10mW/cm2. Note: 2 MPa is the maximum stress accurately measured by the tensometer under these conditions. Stress values greater than this threshold are indicative of greater than 2 MPa stress rather than exact values.