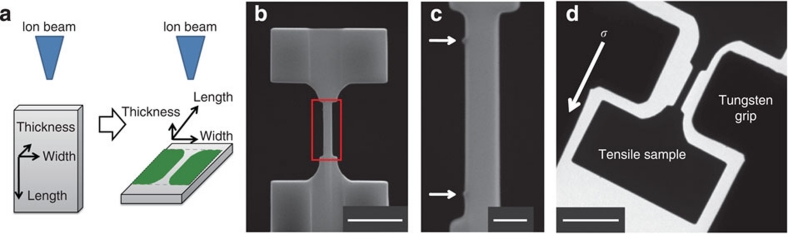

Figure 2. Tensile specimen preparation and experimental setup.

(a) Schematic representation of the FIB procedure for cutting the tensile samples. First a thin plate with dimensions of 400 nm (thickness)×2.5 μm (width)×5 μm (length) was FIB milled from its bulk parent body, with ion beam going through the length direction (left panel). Then a tensile sample was milled into the plate and the ion beam was parallel to the thickness direction (right panel). (b) SEM image of a typical as-fabricated tensile sample. The part framed by the red rectangular box is enlarged in c. The two markers that are critical for the following strain measurement were made by e-beam-induced carbon deposition, as indicated by the white arrows. (d) Low-magnification TEM image showing the experimental setup including the sample, the tungsten grip and the loading direction. The scale bars in b, c and d represent 1 μm, 200 nm and 1 μm, respectively.