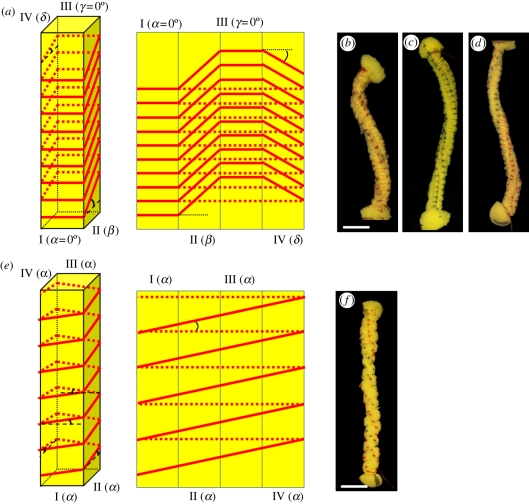

Figure 6.

Sponge models simulating the difference in behaviour of drying plant cell walls with normal and tilted helix alignment of the cellulose microfibrils. Long rectangular cylinder sponge strips (approx. 1.5 × 1.5 × 12 cm3) were threaded loosely to form a helix, either tilted (b–d) or not (f). The thread was then tightened, forming a non-extendable cage restricting the expansion of the isotropic matrix of the sponge. (a) A scheme (right: three-dimensional, left-sides projections) illustrating the threading angles of the tilted helix models: β on side II, and δ on side IV, whereas sides I and III have α = γ= 0°. In (b) tight anticlockwise thread helix with angles of β = +15°, δ = −8° and (c) β = +40°, δ = −33.5° results in a clockwise coiling of the structure. Note that the coiling radius of the structure is reduced in model (c) with the increase in tilt angles. (d) For a clockwise thread helix of β = −40°, and δ = +33.5°, an anticlockwise coil is formed. (e) A scheme (right: three-dimensional, left-sides projections) illustrating the threading angles in the normal helix models. All the sides are threaded at the same angle, α. (f) A normal thread helix with α = +10° produces only a twist with no bending of the structure's longitudinal axis. Scale bar, (b–e,f) 2 cm.