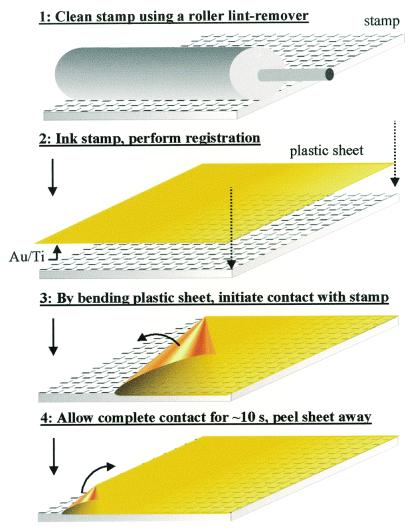

Figure 4.

Procedures for using μCP to pattern over large areas, with low defects, low distortions, and good registration to existing features. The stamp is first placed, printing side up, on a surface that allows strains in the stamp to relax; the stamp is never directly manipulated again. A conventional roller lint remover removes dust from the surface of the stamp. After inking, registration marks on the plastic substrate are aligned with similar marks on the stamp. By gradually unbending the substrate, contact proceeds from the registered edge to the other in a manner that minimizes the formation of trapped pockets of air. Peeling the plastic sheet away from the stamp after maintaining contact for ≈10 s completes the printing.