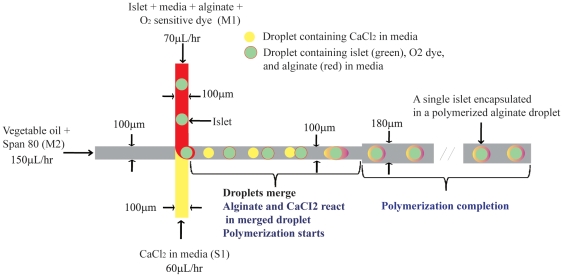

Figure 1. Schematic of microfluidics system used to encapsulate islets.

Islets were encapsulated in polymerized alginate using a microfluidic system with three rectangular inflow channels (100 µm wide) and a single outflow channel (180 µm wide). Each microchannel has a depth of 180 µm. A mixed solution of soybean oil and Span 80 (0.05%), acting as the carrier phase, was pumped through the center microchannel at 150 mL/hr using a syringe pump. Culture media containing 0.05 M CaCl2 (lower microchannel) or islets/alginate (0.2 M)/oxygen-sensitive dye (20 µM) (upper microchannel) was pumped at 60 or 70 mL/hr respectively. At the intersection of the microchannels, the aqueous phases enter the faster flowing oil phase in alternating fashion as discrete droplets. Once in the main channel, the less viscous and slightly faster CaCl2 droplet collides and merges with the more viscous alginate droplet. During the 3-min transit through the outflow channel, calcium causes the alginate surrounding the islet to polymerize thereby encasing both islet and oxygen-sensitive dye by a thin alginate layer.