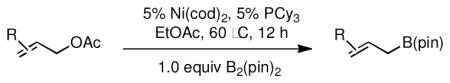

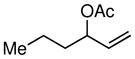

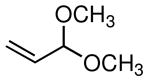

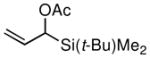

Table 2.

Ni-Catalyzed Allylic Boronate Synthesis from Allylic Acetates.

Isolated yield of purified material. Value is an average of two experiments.

Contains ca. 5% impurity.

Employed 10% catalyst and PPh3.

Employed 10% catalyst.

Product is a 2:1 ratio of E:Z isomers as established by NMR.