Table 4. Effect of Catalytic Sodium Iodide on Yieldab.

| entry | FG | ligand | NaI (mol %) | yield (%)b | product (A%)c | Ar-H (A%)c | alkene/alkanes (A%)c | aryl dimer (A%)c | alkyl dimer (A%)c |

|---|---|---|---|---|---|---|---|---|---|

| 1 | 4-H | 6 | 25 | 86 (3b) | 86 | 3 | 2 | 8 | 1 |

| 2 | 4-H | 6 | 74 (3b) | 79 | 2 | 3 | 13 | 3 | |

| 3 | 4-OMe | 6 | 25 | 73 (3c) | 81 | 4 | 2.5 | 9.5 | 3 |

| 4 | 4-OMe | 6 | 68 (3c) | 75 | 2 | 2 | 16 | 5 | |

| 5 | 4-C(O)Me | 7 | 25 | 84 (3d) | 88 | 4 | 2 | 4 | 2 |

| 6 | 4-C(O)Me | 7 | 63 (3d) | 70.5 | 8 | 3 | 11 | 7.5 |

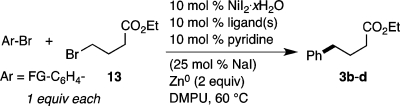

Reaction conditions: organic halides (0.75 mmol each), NiI2·xH2O (0.078 mmol), ligand (0.075 mmol), pyridine (0.075 mmol), sodium iodide (0.19 mmol), zinc dust (>10 μm, 1.5 mmol), and DMPU (3 mL) were assembled on the bench in a 1 dram vial and heated for 15–41 h under air until complete consumption of starting materials.

Yield of isolated and purified product.

The amounts of these products are area % (A%) data.