Table 2.

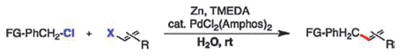

Representative benzylic-alkenyl cross-couplingsa

| |||

|---|---|---|---|

| Entry | Product (Yield)b | Entry | Product (Yield)b |

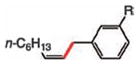

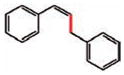

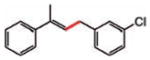

| 1 |

2 (82%) |

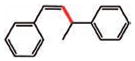

2 |

3 (91%) |

|

|||

| 3 | 4 R = CF3 (84%) | 5 | 6 R = H (95%) |

| 4 | 5 R = Cl (89%) | 6 | 7 R = OMe (81%) |

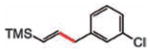

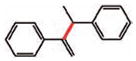

| 7 |

8 (90%) |

8 |

9 (85%) E/Z 83/17c |

| 9 |

10 (77%) E/Z 92/8d |

10 |

11 (95%) |

| 11 |

12 (92%) |

12 |

13 (96%) |

| 13 |

14 (83%) |

14 |

15 (79%)e |

| 15 |

16 (82%) |

||

Conditions: benzylic chloride (2–3 mmol), alkenyl halide (X = I, for entries 1–6, 10, 12, 15, and X = Br for entries 7–9, 11, 13–14; 1 mmol), zinc dust (3–4 mmol), PdCl2(Amphos)2 (0.02 mmol), degassed water (3 mL), rt, 6 h.

Isolated yield.

From commercially available β-bromo-styrene, E/Z = 87/13.

From commercially available (2-bromovinyl)trimethylsilane, E/Z = 93/7.

From commercially available 90% technical grade a-bromostyrene.