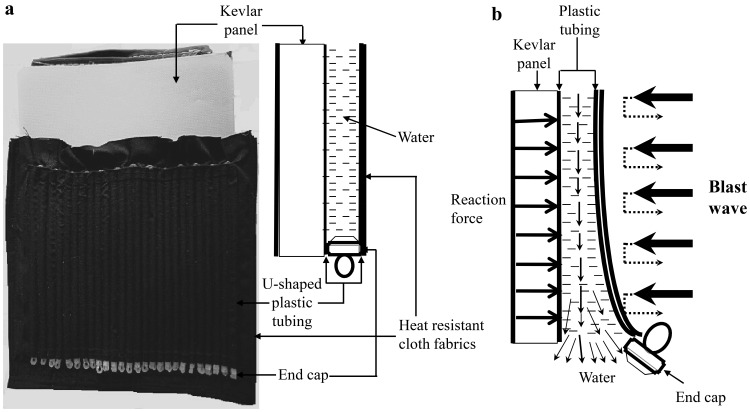

Figure 1. The structure of specifically designed body armor sample and its potential mechanism for blast shock wave mitigation.

(a) A photograph showing the sample of the body armor that includes the water-filled plastic tubings, end caps, Kevlar panel, and heat resistant cloth fabrics; (b) A schematic diagram illustrating a side view of the sample of the body armor after a blast shock wave impacts the sample. The rapid compression effects of blast shock wave on the sample create an action force to compress water-filled plastic tubing and make it move against the Kevlar panel. Because the Kevlar panel is a hard plate fixed on a test frame, it will exert a reaction force against the plastic tubing. The action and reaction forces push water moving towards the lower end of the plastic tubing. Since water is incompressible, increased liquid pressure on the lower end forces the end cap to open and make water to spray out through the opening from the tubin, thus rapidly decreasing the liquid pressure inside of the tube.