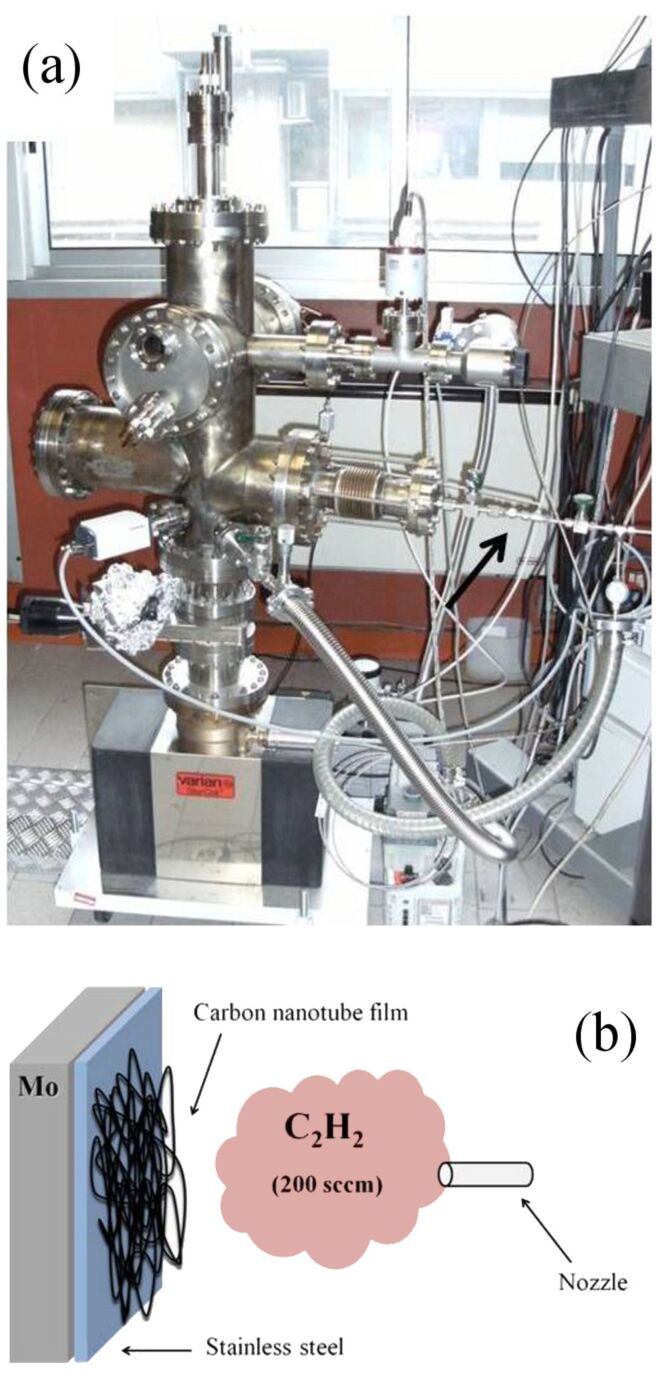

Figure 1.

(a) Photograph of the chemical vapour deposition chamber used to synthesize MWCNTs. The reactor comprises an UHV chamber, pumped by an ion pump and equipped with a manipulator capable of reaching temperatures of about 800–900 °C. Acetylene and argon fluxes, introduced in the chamber through the gas line highlighted by the arrow, are adjusted by means of two suitable valves. (b) Schematics showing the CVD process: The stainless-steel substrate is mounted on a heatable molybdenum sample holder. After a temperature of 750 °C has been achieved, acetylene gas (200 sccm) is inserted through a nozzle in the chamber under an Ar atmosphere.