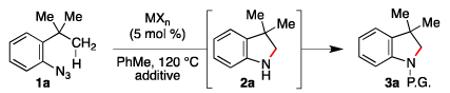

Table 1.

Development of Optimal Conditions.

| entry | catalyst | additive | conv., %a |

yield, %b |

|---|---|---|---|---|

| 1 | none | n.a. | 0 | 0 |

| 2 | FeBr2 | n.a. | 0 | decc |

| 3 | CuBr | n.a. | 0 | 0 |

| 4 | CoTPP | n.a. | 0 | 0 |

| 5 | RuCl3•nOH2 | n.a. | 0 | 0 |

| 6 | [Ir(cod)OMe]2 | n.a. | 0 | 0 |

| 7 | [Rh(cod)OMe]2 | n.a. | 10 | 0c |

| 8 | Rh2(O2CC7H15)4 | n.a. | 35 | 35 |

| 9 | Rh2(esp)2 | n.a. | 99 | 75 |

| 10 | Rh2(esp)2 | Boc2O | 99 | 90 |

| 11 | Rh2(esp)2 | Ac2O | 99 | 83 |

| 12 | Rh2(esp)2 | Bz2O | 99 | aniline |

| 13 | Rh2(esp)2 | Tf2O | 99 | aniline |

As determined using 1H NMR spectroscopy.

Isolated after silica gel chromatography.

Aniline formed.