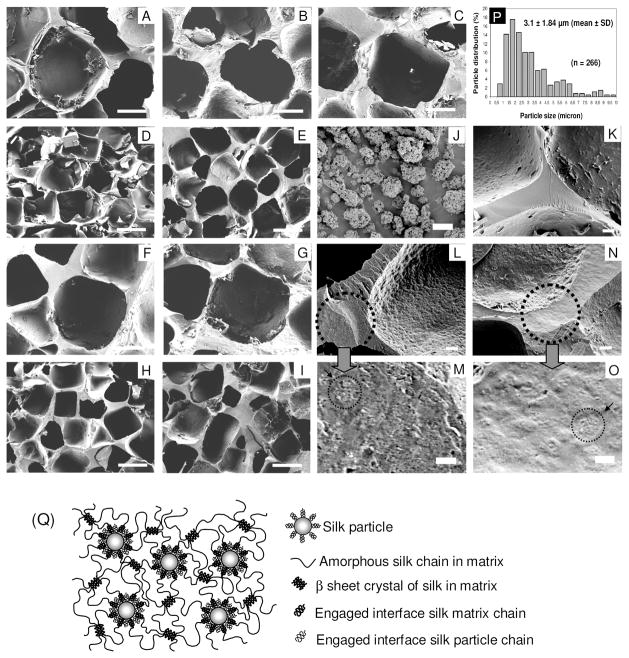

FIGURE 2.

SEM images of the silk particle-reinforced silk scaffolds. The 1:0 scaffolds-500~600 μm pore size (A), 1:1 scaffolds-SP-500~600 μm pore size (B), 1:2 scaffolds-500~600 μm pore size (C), 1:0 scaffolds--210~300 μm pore size (D), 1:2 scaffolds-210~300 μm pore size (E), 2:0 scaffolds-500~600 μm pore size (F), 2:1 scaffolds--500~600 μm pore size (G), 2:0 scaffolds-210~300 μm pore size (H), 2:1 scaffolds-210~300 μm pore size (I), B. mori silk fibroin particles (J), wall fracture image of the 2:0 scaffolds-500~600 μm pore size (K), wall fracture image of the 1:2 scaffolds-500~600 μm pore size (L and M), wall fracture image of the 2:1 scaffolds-210~300 μm pore size (N and O). Histogram of silk particle size distribution (P), Schematic model showing a good miscibility between silk matrix and silk particles (Q): Random coiled silk chains on the interface of silk matrix and silk particles are wetted together because of good miscibility. Scale bars 200 μm in (A–I), 20 μm in (K, L, N), and 5 μm in (J, M, O).