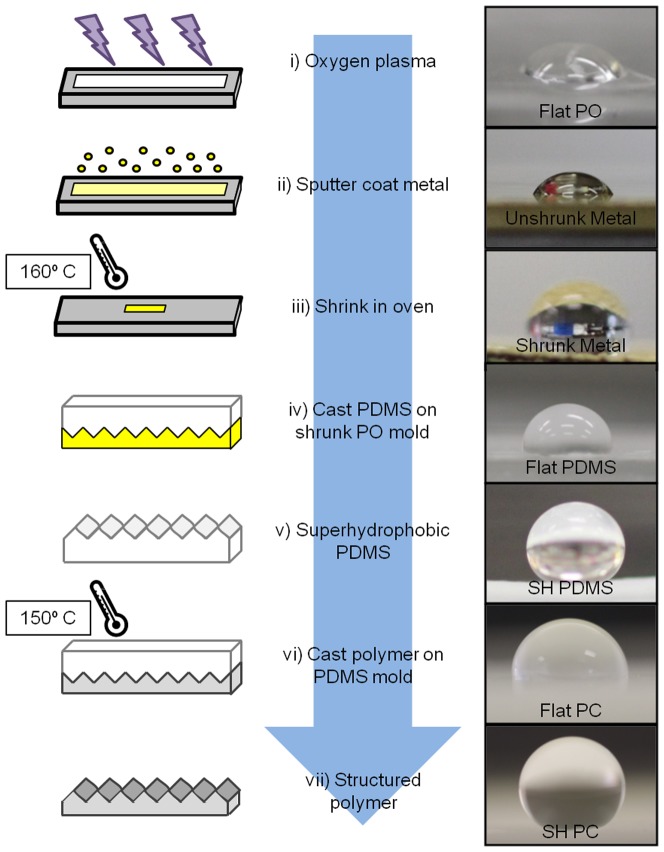

Figure 1. Process flow of the superhydrophobic substrates formed from shrink film paired with their respective CA.

(i) PO film is plasma treated with oxygen for 30 seconds (ii) Treated PO film is sputter coated with 60 nm of silver and 60 nm of gold (iii) PO film is shrunk at 160°C to induce buckling and folding (iv) PDMS is poured over fully shrunk PO film for casting (paired photo features flat PDMS) (v) Superhydrophobic PDMS cast is removed from shrunk PO (vi) Hard plastics are casted into superhydrophobic PDMS mold by applying pressure and heat (paired photo features flat PC) (vii) Superhydrophobic PC casted from superhydrophobic PDMS.