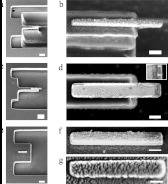

Figure 4.

SEM images of the chip’s leading edge (left) and the corresponding magnified images of the associated magnets (right) produced by three release protocols: a chip with an overhanging nanomagnet, released prior to magnet deposition by a BOE wet etch [panels (a) and (b)]; a chip with an overhanging nanomagnet, released by HF vapor after magnet deposition [panels (c) and (d)]; and a chip with a nonoverhanging magnet, released prior magnet deposition with a BOE wet etch [panels (e)–(g)]. It can be seen in the inset in panel (d) that releasing with HF vapor damaged the magnet’s leading edge; the arrows highlight the leading 20 nm of the magnet in which only the chromium adhesion layer is intact. The magnet in panel (g) is coated with approximately 6 nm of alumina prepared by atomic layer deposition. The magnets in panels (b) and (f) are undamaged and uncapped. The scale bars in (a), (c), and (e) was . The scale bars in (b), (d), (f), and (g) was 200 nm.