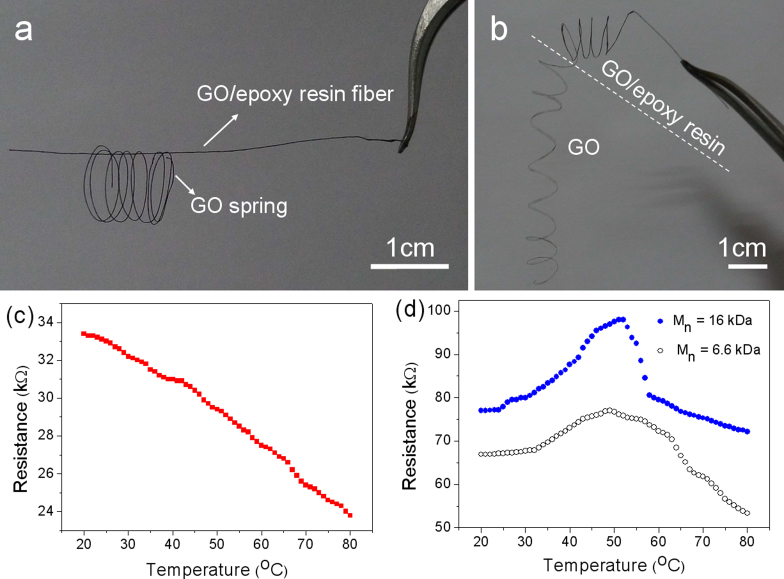

Figure 5. Multifunctionalization of the macroscopic graphene-based fibers.

Photographs of (a) a GO/epoxy resin fiber supporting a GO spring; (b) a spring with two halves, one the GO/epoxy resin fiber, the other GO fiber. The GO/epoxy resin fiber was prepared by soaking the GO fiber of 10 mg/mL into epoxy resin solution followed with thermal solidification. (c) Curve of resistance change with temperature of a single graphene fiber. (d) R-T curves of a single graphene/PNIPAM composite fiber by wet-spinning of GO-PNIPAM dopes followed with chemical reduction (GO suspensions of 5 mg/mL, the weight ratio of GO and PNIPAM of 1:1). Two kinds of molecular weights of PNIPAM were used (16 kDa and 6.6 kDa).