Abstract

Eight- and four-membered analogues of N-butyldeoxynojirimycin (NB-DNJ), a reversible male contraceptive in mice, were prepared and tested. A chiral pool approach was used for the synthesis of the target compounds. Key steps for the synthesis of the eight-membered analogues involve: ringclosing metathesis and Sharpless asymmetric dihydroxylation, and for the four-membered analogues: Sharpless epoxidation, epoxide ring opening (azide), and Mitsunobu reaction to form the four-membered ring. (3S,4R,5S,6R,7R)-1-Nonylazocane-3,4,5,6,7-pentaol (6), was moderately active against rat-derived ceramide-specific glucosyltransferase and four of the other eight-membered analogues were weakly active against rat-derived β-glucosidase 2. Among the four-membered analogues, ((2R,3s,4S)-3-hydroxy-1-nonylazetidine-2,4-diyl)dimethanol (25), displayed selective inhibitory activity against mouse-derived ceramide-specific glucosyltransferase and was about half as potent as NB-DNJ against the rat-derived enzyme. ((2S,4S)-3-Hydroxy-1-nonyl-azetidine-2,4-diyl)dimethanol (27) was found to be a selective inhibitor of β-glucosidase 2, with potency similar to NB-DNJ. Additional glycosidase assays were performed to identify potential other therapeutic applications. The eight-membered iminosugars exhibited specificity for almond-derived β-glucosidase and the 1-nonylazetidine 25 inhibited α-glucosidase (Saccharomyces cerevisiae) with an IC50 of 600 nM and β-glucosidase (almond) with an IC50 of 20 µM. Only N-nonyl derivatives were active, emphasizing the importance of a long lipophilic side chain for inhibitory activity of the analogues studied.

Introduction

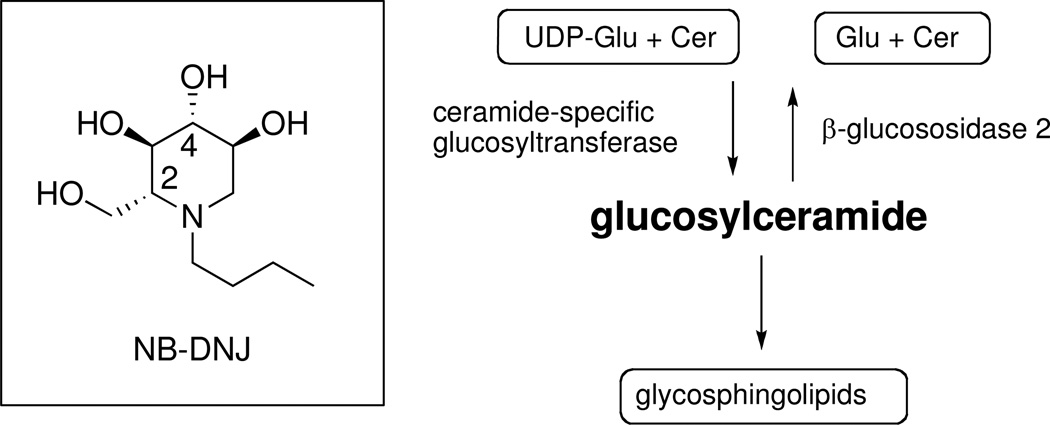

Hormonal male contraceptive agents are currently in clinical trials, but have not yet reached the market due to side effects, and pharmacokinetic issues.1 The discovery and development of non-hormonal contraceptive agents is another approach towards male contraception.2 Non-hormonal experimental agents such as gossypol3 and alpha-chlorohydrin4 have been studied, but they are neither safe nor effective enough for human use. Among newer non-hormonal contraceptive lead compounds,5 the alkylated iminosugar N-butyldeoxynojirimycin (NB-DNJ, Zavesca®) has been reported to be an effective, reversible, and non-toxic oral male contraceptive agent in mice (Figure 1).6 NB-DNJ is in clinical use for the treatment of mild-to-moderate type 1 Gaucher’s disease in adult patients who cannot be treated with enzyme replacement therapy (ERT).7

Figure 1.

Structure of N-butyldeoxynojirimycin (NB-DNJ) and metabolism of glucosylceramide.

The iminosugar NB-DNJ (Figure 1) is an inhibitor of ceramide-specific glucosyl transferase,8 and β-glucosidase 2, which are key enzymes (Figure 1 and Table 1) in the biosynthesis of glycosphingolipids.9,10 Inhibition of these enzymes leads to an imbalance of testicular glucosylceramide levels, which is believed to impair spermatogenesis. The effect of NB-DNJ on spermatogenesis was found to be species- and strain-specific.11 NB-DNJ is active in C57B1/6J-related mouse strains but not in other mouse strains or in rabbits. Although NB-DNJ also showed no discernible effects on human spermatogenesis,12 we hypothesized that analogues of NB-DNJ with higher potency and or differential enzyme selective inhibitory activity could be discovered that would affect spermatogenesis in mammalian species other than C57B1/6J-related mouse strains, including man.

Table 1.

Inhibition of Ceramide-specific Glucosyltransferase and β-Glucosidase 2 by Iminosugar Analogues 1–6 and 22–27.a

| ceramide-specific glucosyltransferase | β-glucosidase 2 | ||

|---|---|---|---|

| inhibitor | IC50 (C57BL/6, mouse) µM | IC50 (LE rat) µM | IC50 (LE rat) µM |

| *NB-DNJ | 51b | 32 | 81 |

| 1 | n.i. | n.i. | n.i. |

| 2 | n.i. | n.i. | 803 |

| 3 | n.i. | n.i. | 1123 |

| 4 | n.i. | n.i. | 904 |

| 5 | n.i. | n.i. | n.i. |

| 6 | n.i. | 127 | 766 |

| 22 | >300 | >300 | >300 |

| 23 | >300 | >300 | >300 |

| 24 | >300 | >300 | >300 |

| 25 | 44 | 91 | >300 |

| 26 | >300 | >300 | >300 |

| 27 | >300 | >300 | 70 |

The details of the enzyme inhibition studies are described in the supporting information; n.i., no inhibition at 1000 µM concentration.

NB-DNJ inhibits HL60 cell-derived ceramide-specific glucosyltransferase with an IC50 of 20.4 µM13d and a Ki of 7.4 µM.13a

Mouse-derived testicular ceramide-specific glucosyltransferase was inhibited with an IC50 = 23 µM and testicular mouse-derived β-glucosidase 2 with an IC50 = 0.14.10

Five-, six- and seven-membered NB-DNJ analogues13 have been reported as inhibitors for ceramide-specific glucosyltransferase, but none of them are significantly better inhibitors than NB-DNJ except N-alkyloxyalkyl DNJ analogues14 including adamantane-DNJ conjugates.15 Six- and seven-membered ring DNJ analogues have also been investigated for pharmacological chaperoning to improve protein folding and trafficking defects in Gaucher’s disease.16 More potent analogues and derivatives effective in all mammalian species could possibly be obtained by structural changes of the parent compound, which includes ring-enlarged or ring-contracted analogues related to NB-DNJ such as azocane analogues (eight-membered ring) and azetidine analogues (four-membered ring). A series of azetidine analogues were recently reported as inhibitors of various glycosidases,17 but they were not tested against ceramide-specific glucosyltransferase. We report herein the design and synthesis of novel eight-membered and four-membered iminosugar analogues and the evaluation of their inhibitory potencies for testicular ceramide-specific glucosyltransferase, testicular β-glucosidase 2, and other glycosidase enzymes. The key synthetic steps for the synthesis of the eight-membered analogues involved a ring closing metathesis and a Sharpless asymmetric dihydroxylation. The four-membered iminosugars were prepared from l-gulono-1,4-lactone or 1,2:5,6-diisopropylidene-d-mannitol, employing as the key steps a Sharpless epoxidation and a Mitsunobu reaction for ring formation.

Results/Discussion

Design and synthesis of eight-membered iminosugars

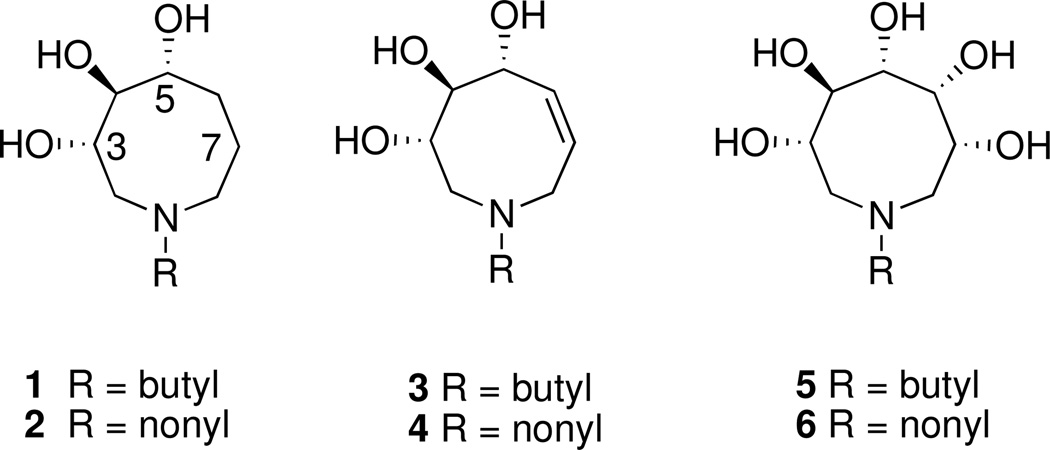

Molecular models of eight-membered iminosugars 2, 4, and 6 (Figure 2) were generated using Maestro (Schrödinger, LLC). The ceramide structure was prepared based on the crystal structure of galactosylceramide.13a, 18

Figure 2.

Structures of designed eight-membered iminosugar analogues 1–6.

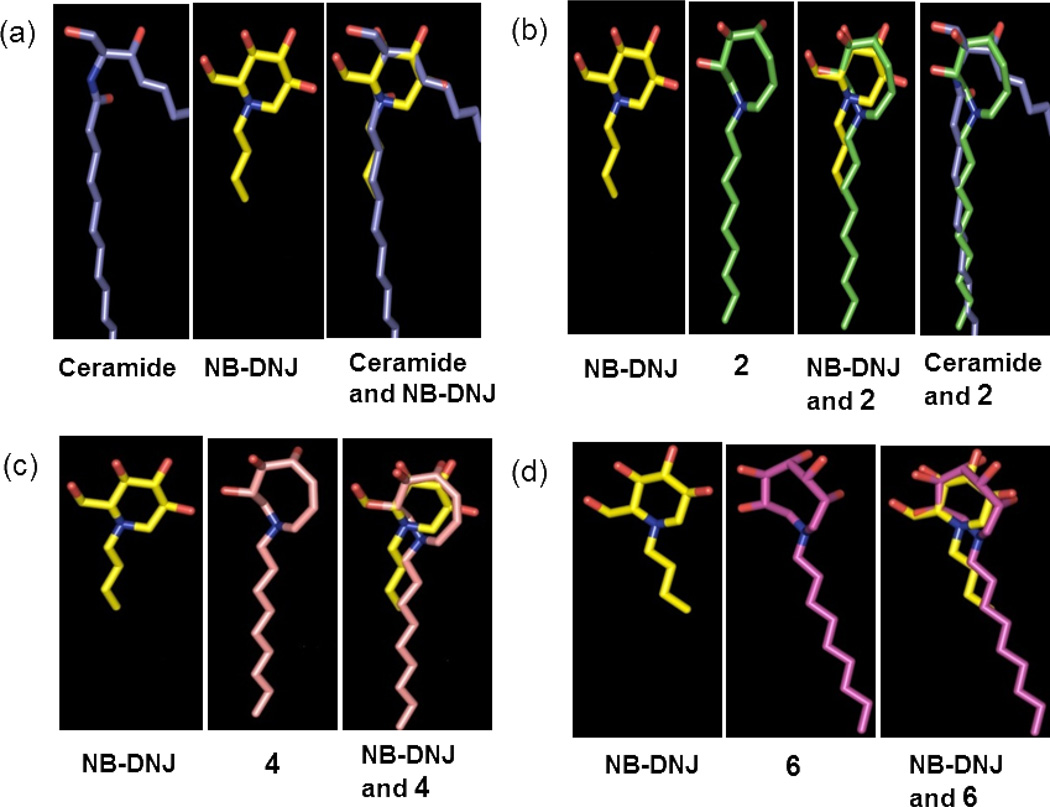

Figure 3a shows the overlay of NB-DNJ and ceramide.13a Overlay of compound 2 with NB-DNJ (Figure 3b) demonstrates that the 4-hydroxyl, 3-hydroxyl and the 2-hydroxymethyl groups of NB-DNJ have a similar orientation as the 5-hydroxyl, 4-hydroxyl and 3-hydroxyl groups of compound 2 respectively. The introduction of a double bond into the 8-membered ring slightly changes the ring conformation (compounds 3 and 4). Nevertheless, overlay of compound 4 with NB-DNJ (Figure 3c) was very similar to that of compound 2. Next, two additional hydroxyl groups were added to the ring (compounds 5 and 6) and then assessed for structural similarity to NB-DNJ. In the overlay of compound 6 with NB-DNJ (Figure 3d), the 7-hydroxyl group of compound 6 is close to the 5-hydroxyl group of NB-DNJ. The 6- hydroxyl group of 6, however, does not overlay with any of the hydroxyl groups in NB-DNJ. The modeling study reveals that the designed six eight-membered iminosugars possess structural similarities with NB-DNJ and therefore could be expected to be inhibitors of the targeted enzymes.

Figure 3.

Molecular modeling of ceramide, NB-DNJ and designed compounds 2, 4 and 6.

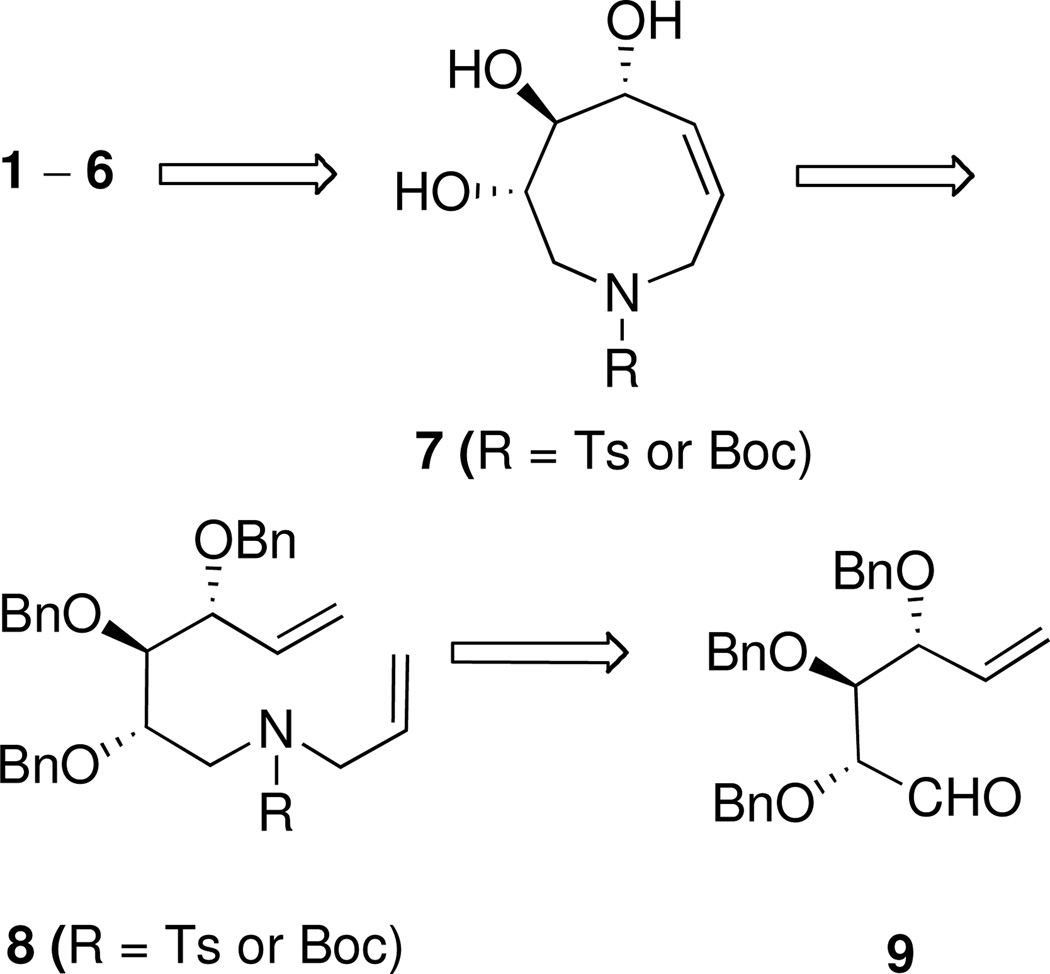

The retrosynthetic approach for the synthesis of the eight-membered iminosugars is outlined in Scheme 1. The six target compounds would be prepared from common intermediate 7, which could be formed through a ring closing metathesis of diene 8. Diene 8 would be generated by a reductive amination of aldehyde 9 with allylamine.

Scheme 1.

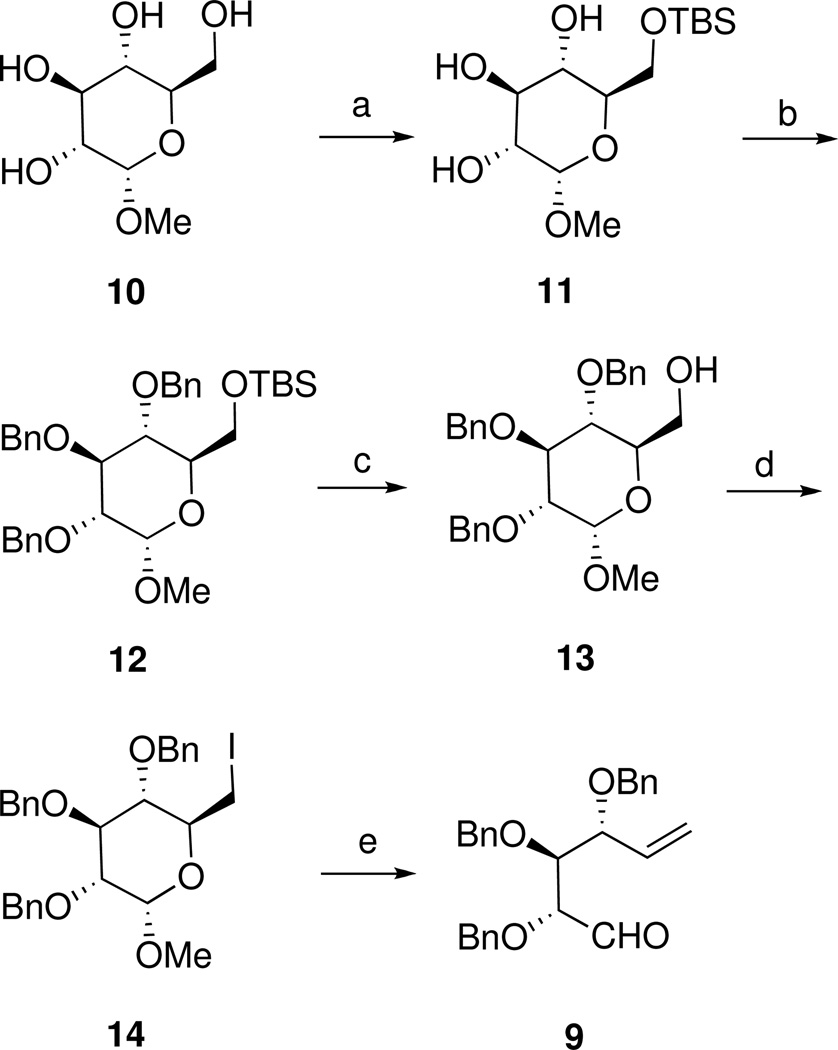

Compound 9 was prepared as shown in Scheme 2, utilizing known procedures.19,20 The primary hydroxyl group of methyl-α-d-glucopyranoside (10) was protected as its TBS ether 11. Benzylation of intermediate 11 provided the fully protected compound 12, which was desilylated with TBAF to afford the primary alcohol 13. Iodination of alcohol 13 was performed with iodine and triphenylphosphine to provide the iodo intermediate 14, which underwent reductive ring opening with activated zinc under sonication conditions21 to furnish aldehyde 9 in good yield.

Scheme 2a.

a Reagents and conditions: (a) TBSCl, imidazole, DMF, 0 °C to rt, 16 h, 72%; (b) NaH, benzyl bromide, DMF, rt, 17 h, 72%; (c) TBAF, THF, rt, 16 h, 99%; (d) I2, PPh3, imidazole, toluene, 70 °C, 3 h, 94%; (e) Zn, THF/H2O, sonication at 40 °C, 2 h, 93%.

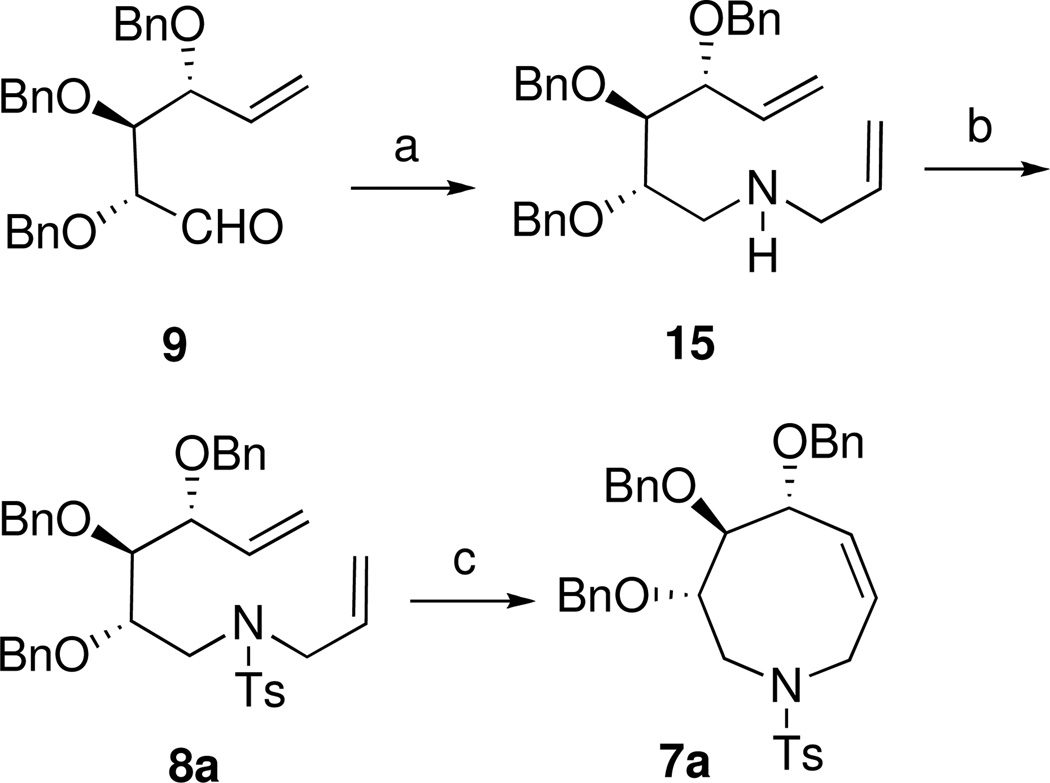

The synthesis of the eight-membered ring was performed as shown in Scheme 3. Reductive amination22 of aldehyde 9 with allylamine using NaBH(OAc)3 afforded diene 15. The secondary amine of the diene was protected with a tosyl group to yield compound 8a. Ring closing metathesis (RCM)23 was then performed using the Grubbs II catalyst to obtain the eight-membered ring 7a.

Scheme 3a.

a Reagents and conditions: (a) allylamine, NaBH(OAc)3, ClCH2CH2Cl, rt, 16 h, 86%; (b) TsCl, TEA, DMAP, CH2Cl2, rt, 3 h, 84%; (c) Grubbs II catalyst, CH2Cl2, reflux, 1 h, 84%.

The amino group of intermediate 15 was also protected with a Boc group to provide compound 8b (Scheme 4) although in a slightly lower yield than the N-tosylation reaction of 15. RCM reaction of 8b yielded compound 7b as a mixture of two Boc-rotamers in a ratio of 1: 1.4. This reaction provided the targeted compound 7b in slightly better yield than the reaction of N-tosyl derivative 8a to form RCM product 7a.

Scheme 4a.

a Reagents and conditions: (a) Boc anhydride, DMAP, CH2Cl2, rt, 16 h, 80%; (b) Grubbs II catalyst, CH2Cl2, reflux, 4 h, 92%.

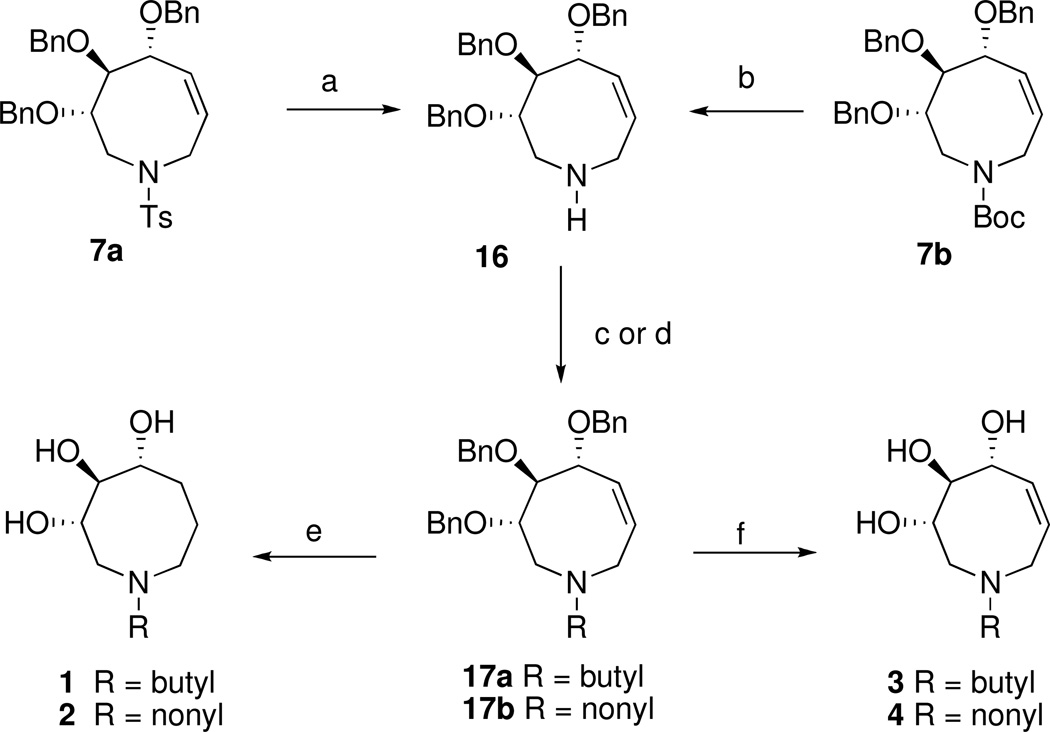

With key intermediates 7a and 7b in hand, the tri-hydroxy compounds 1–4 were obtained as shown in Scheme 5. The tosyl group of compound 7a was cleaved using Na and naphthalene to provide secondary amine 16.24 Amine 16 was also prepared from intermediate 7b by removal of the Boc group. Removal of the Boc group provided a slightly higher yield than the deprotection of the tosyl group. Comparing the two protecting groups in this reaction sequence reveals that the N-tosyl and N-Boc protecting groups lead to the same overall yield for the synthesis of intermediate 16 from 15. Reductive alkylation of the secondary amine22 16 was carried out next, using butyraldehyde and nonyl aldehyde to afford compounds 17a and 17b respectively. Debenzylation and double bond reduction was achieved with hydrogen gas, using palladium (II) chloride as the catalyst, to obtain target compounds 1 and 2. Reductive debenzylation25 of compounds 17a and 17b was performed using Li and naphthalene to provide the tri-hydroxy derivatives 3 and 4.

Scheme 5a.

Reagents and conditions: (a) Na, naphthalene, DME, −78 °C, 30 min, 75%; (b) 4N HCl in dioxane, rt, 1 h, 85%; (c) butyraldehyde, NaBH(OAc)3, ClCH2CH2Cl, rt, 16 h, 75%; (d) nonyl aldehyde, NaBH(OAc)3, ClCH2CH2Cl, rt, 16 h, 76%; (e) PdCl2, MeOH, H2, rt, 16 h, 76% for 1, 78% for 2; (f) Li, liquid NH3, THF, −78 °C, 1 h, 59% for 3, 66% for 4.

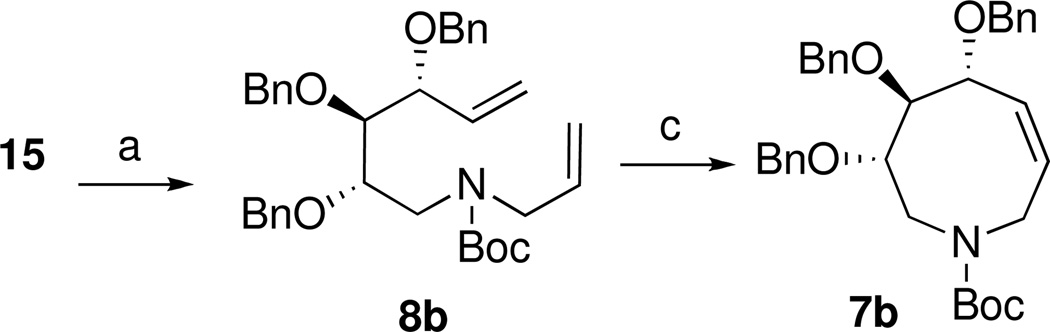

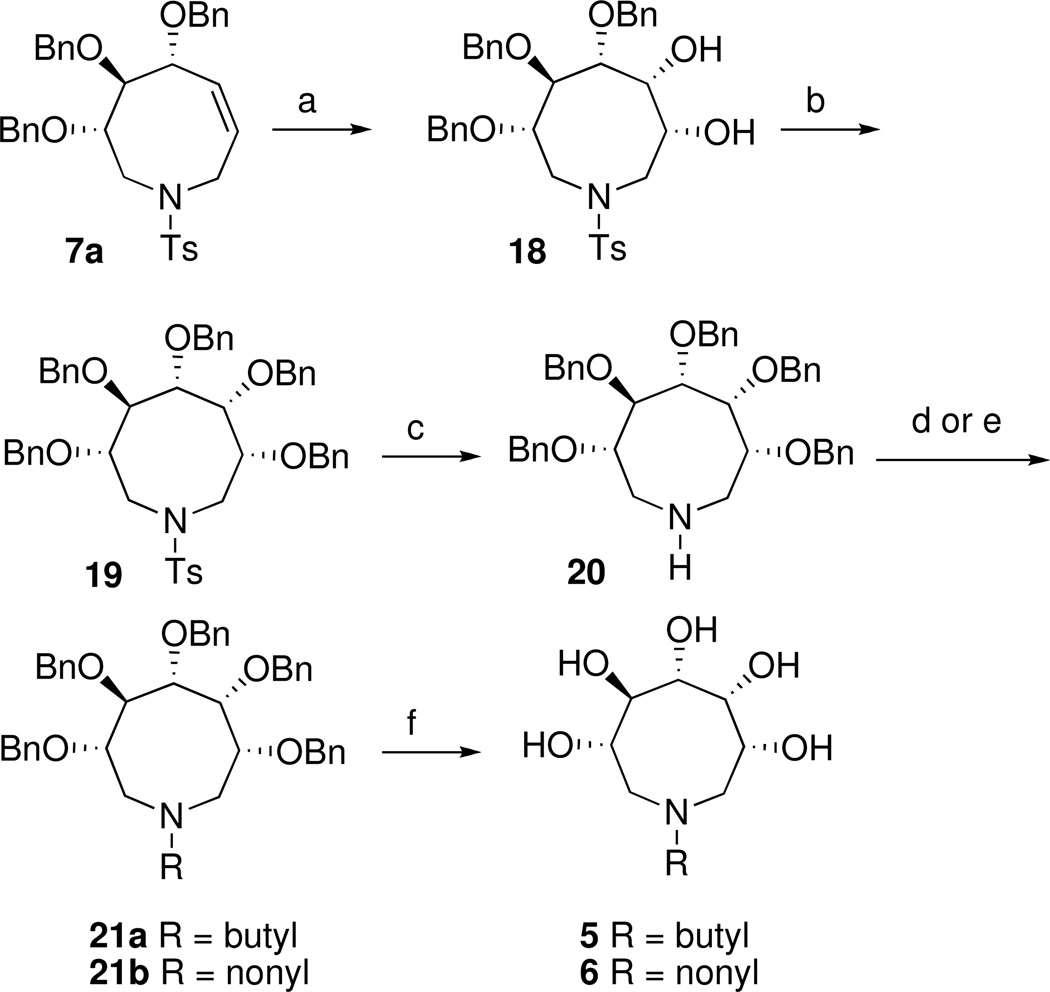

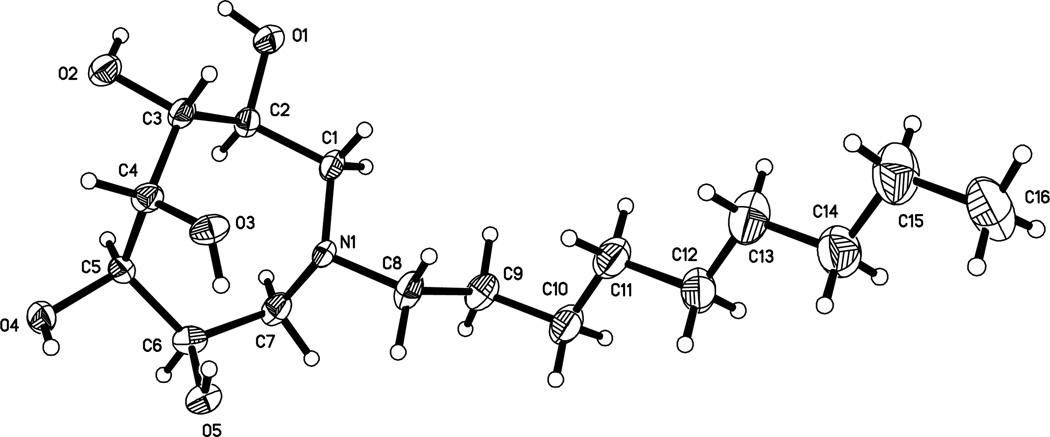

The synthesis of pentahydroxy derivatives 5 and 6 was also achieved from common intermediate 7a (Scheme 6). First, the cis-diol moiety was introduced into compound 7a by a catalytic Sharpless cisasymmetric dihydroxylation26 to provide diol 18. A non-asymmetric dihydroxylation was also performed using OsO4, but the reaction provided an inseparable mixture of reaction products. Diol 18 was then benzylated to form pentabenzyl ether 19. Benzylation of 18 provided advantages such as clean reactions and ease of purification in the following reaction steps. Reductive detosylation of 19 gave secondary amine 20. Reductive alkylation of the secondary amine was performed using butyraldehyde and nonyl aldehyde to furnish compounds 21a and 21b respectively. Finally, hydrogenolysis of compounds 21a and 21b afforded the corresponding penta-hydroxyazocanes 5 and 6. The structure of penta-hydroxyazocane 6 was confirmed by single crystal X-ray crystallography (Figure 4).

Scheme 6a.

a Reagents and conditions: (a) (DHQ)2-PHAL, K2OsO2(OH)4, K2CO3, K3(FeCN)6, CH3SO2NH2, THF/t-BuOH/H2O, rt, 40 h, 82%; (b) NaH, BnBr, DMF, rt, 15 h, 87%; (c) Na, naphthalene, DME, −78 °C, 30 min, 72%; (d) butyraldehyde, NaBH(OAc)3, ClCH2CH2Cl, rt, 16 h, 79%; (e) nonyl aldehyde, NaBH(OAc)3, ClCH2CH2Cl, rt, 16 h, 84%; (f) PdCl2, MeOH, H2, rt, 18 h, 80% for 5, 74% for 6.

Figure 4.

X-ray structure of penta-hydroxyazocane 6.

Design and synthesis of four-membered iminosugar analogues

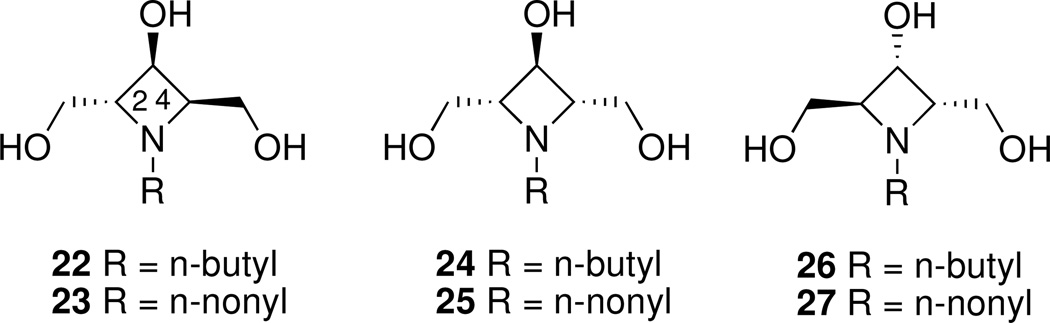

Six four-membered iminosugars, 22–27, were designed and synthesized (Figure 5).

Figure 5.

Structures of designed four-membered iminosugars 22–27.

As shown in Figure 6, using Maestro (Schrödinger. LLC) NB-DNJ was overlaid with compounds 23, 25 and 27 (Figures 6a, 6b and 6c respectively). Compound 25 was also overlaid with ceramide (Figure 6d). The 2-hydroxymethyl, 3-hydroxyl, and 4-hydroxymethyl groups of compound 23 align well with the 4-hydroxyl, 3-hydroxyl, and 2-hydroxymethyl groups of NB-DNJ (Figure 6a). As for compound 25, only the 4-hydroxymethyl group was not aligned with NB-DNJ. Overlay of NB-DNJ with compound 27 shows that the 2-hydroxymethyl and the 3-hydroxyl groups are close to the 4-hydroxyl and 3-hydroxyl groups of NB-DNJ respectively. Compound 25 aligned very well with ceramide (Figure 6d, N-acyl chain, N, C2, C3 and the 3-hydroxyl group). Compound 23 aligned well with ceramide similar to compound 25 (picture not shown). The only difference between compound 23 and 25 is the stereochemistry at C4. As a result of the modeling study, we concluded that the designed six four-membered iminosugars are good structural mimics of NB-DNJ and ceramide.

Figure 6.

Overlay of ceramide, NB-DNJ and designed compounds 23, 25 and 27.

The synthesis of the four-membered iminosugars (Scheme 7) started by subjecting L-glyceraldehyde acetonide (28) to a Wittig reaction, followed by DIBAL-H reduction to furnish allylic alcohol 29. Sharpless epoxidation and protection of the hydroxyl group provided epoxide 30. Next, the epoxide was opened with sodium azide, and then the secondary hydroxyl group was benzylated to yield benzyl ether 31. The azide group was reduced with LiAlH4 and the resulting amino group was reacted subsequently with tosyl chloride to form tosylate 32. The acetonide protecting group of intermediate 32 was removed and the primary alcohol was next converted to silyl ether 33. Ring closure to the four-membered ring was accomplished by a Mitsunobu reaction, which was followed by reductive removal of the N-tosyl group to furnish azetidine 34. Azetidine 34 was subjected to reductive amination with butyraldehyde and nonyl aldehyde followed by desilylation to afford intermediates 35a and 35b. Hydrogenolysis of the benzyl protecting groups yielded the targeted four-membered (2R,4R)-3-hydroxyazetidines 22 and 23.

Scheme 7a.

a Reagents and conditions: (a) (Carbethoxymethylene)triphenylphosphorane, benzene, reflux, 74%; (b) DIBAL-H, CH2Cl2, −78 °C to 0 °C, 93%; (c) cumene hydroperoxide, (+)-DIPT, Ti(OiPr)4, 3Å molecular sieves, CH2Cl2, ,−40 °C, 79%; (d) NaH, benzyl bromide, TBAI, THF, rt, 1 h, 96%; (e) NaN3, NH4Cl, 2-methoxyethanol–water 9:1, reflux; (f) NaH, benzyl bromide, TBAI, THF, rt, 1h, 78% over two steps; (g) LiAlH4, THF; (h) tosyl chloride, triethylamine, CH2Cl2, rt, 90% over two steps. (i) 2N HCl: methanol, 40 °C; (j) TBSCl, triethylamine, DMAP, CH2Cl2, 85% over two steps; (k) triphenylphosphine, DIAD, CH2Cl2, rt; (l) Na, naphthalene, DME, −60 °C, 60% over two steps; (m) aldehyde (butyraldehyde or nonyl aldehyde), sodium triacetoxyborohydride, ClCH2CH2Cl, rt, 70% and 72% respectively over two steps; (n) TBAF, THF, rt; (o) PdCl2, H2, methanol, 65% and 70% respectively.

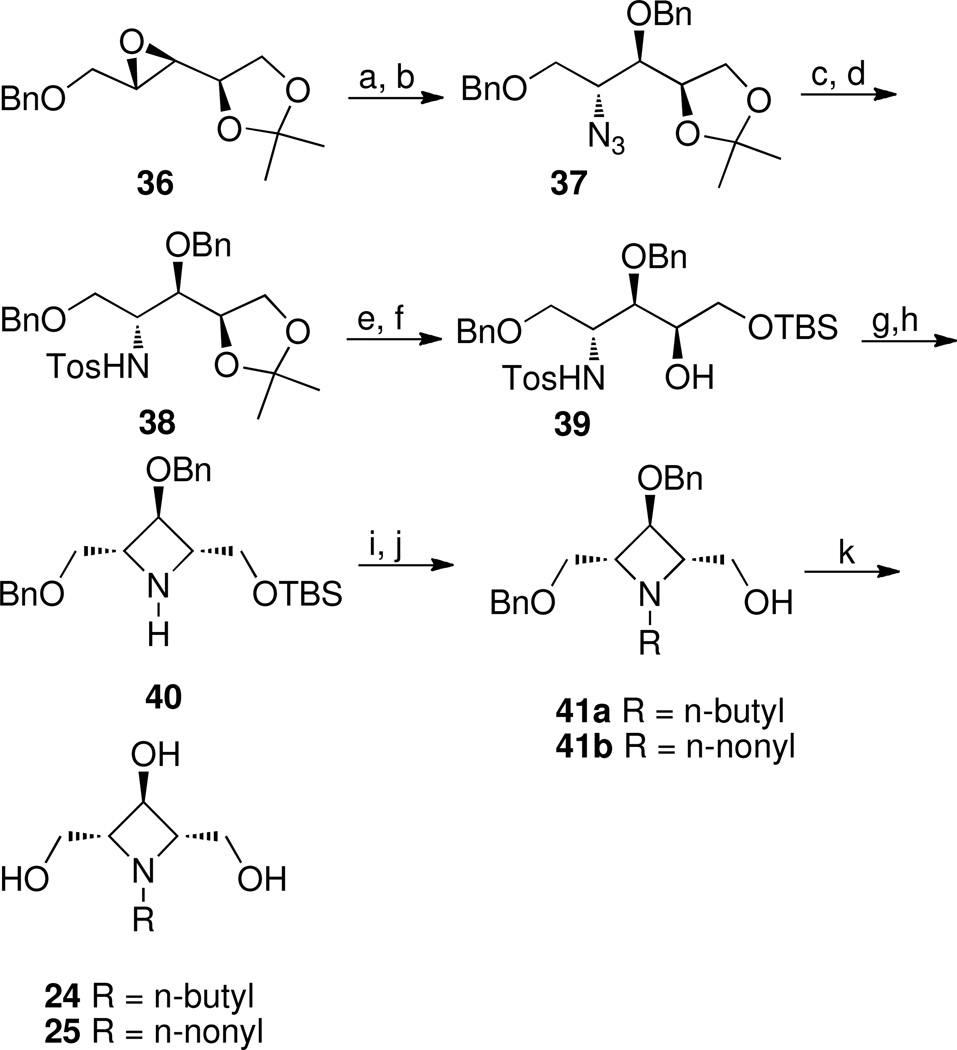

Starting with known epoxyacetonide 36 and following the same synthesis procedures as shown in Scheme 7 furnished the (2R,3s,4S)-3-hydroxyazetidines 24 and 25 (Scheme 8).

Scheme 8a.

a Reagents and conditions: (a) NaN3, NH4Cl, 2-methoxyethanol, water 9:1, reflux; (b) NaH, benzyl bromide, TBAI, THF, rt, 1 h 70% over two steps; (c) LiAlH4, THF; (d) tosyl chloride, triethylamine, CH2Cl2, rt, 90% over two steps (e) 2N HCl: methanol, 40 °C; (f) TBSCl, triethylamine, DMAP, CH2Cl2, 89% over two steps; (g) PPhe3, DIAD, CH2Cl2, rt; (h) Na, naphthalene, DME, −60 °C, 53% over two steps; (i) aldehyde (butyraldehyde or nonyl aldehyde), sodium triacetoxyborohydride, ClCH2CH2Cl, rt; (j) TBAF, THF, rt 73 and 80% respectively over two steps; (k) PdCl2, H2, methanol, 74 and 80% respectively.

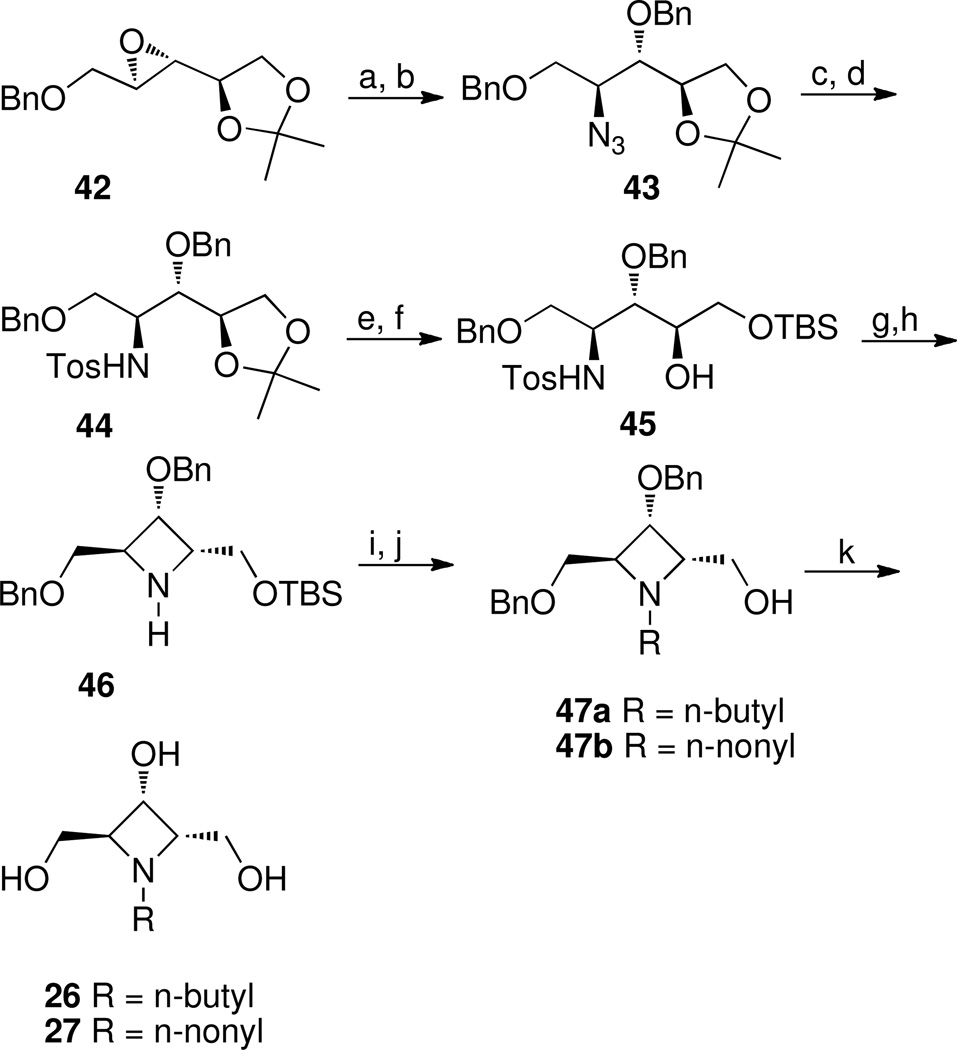

Similarly, starting from epoxyacetonide 42 and following the same procedures shown above in Schemes 7 and 8, the (2S,4S)-3-hydroxyazetidines 26 and 27 were prepared (Scheme 9).

Scheme 9a.

aReagents and conditions: (a) NaN3, NH4Cl, 2-methoxyethanol, water 9:1, reflux; (b) NaH, benzyl bromide, TBAI, THF, rt, 1 h, 70% over two steps; (c) LiAlH4, THF; (d) tosyl chloride, triethylamine, CH2Cl2, rt, 88% over two steps (e) 2N HCl: methanol, 40 °C; (f) TBSCl, triethylamine, DMAP, CH2Cl2, 87% over two steps; (g) PPhe3, DIAD, CH2Cl2, rt; (h) Na, naphthalene, DME, −60 °C, 55% over two steps; (i) aldehyde (butyraldehyde or nonyl aldehyde), sodium triacetoxyborohydride, ClCH2CH2Cl, rt; (j) TBAF, THF, rt 72% and 76% respectively over two steps; (k) PdCl2, H2, methanol 68% and 74% respectively.

Enzyme Inhibition Studies

Compounds 1–6 and 22–27 were tested (Table 1) for inhibition of ceramide-specific glucosyltransferase derived from C57BL/6 mouse and Long Evans (LE) rat testicular microsomes and LE rat-derived testicular β-glucosidase 2. NB-DNJ was used as the positive control. Compounds 1–5, 22–24 and 26–27 did not inhibit rat or mouse ceramide-specific glucosyltransferase; however, N-nonylazocane derivative 6 showed moderate inhibition (IC50 = 127 µM) of the rat-derived ceramide-specific glucosyltransferase (Table 1). N-Nonylazetidine derivative 25 was as active as NB-DNJ against mouse-derived ceramide-specific glucosyltransferase (IC50 = 44 µM) and moderately active against rat-derived ceramide-specific glucosyltransferase (IC50 = 91 µM). The result suggests that the C6 and C7 hydroxyl groups and the longer alkyl chain in the eight-membered analogue 6 are important for activity. As shown with the overlays in Figure 3, the 7-hydroxyl group of compound 6 matches the 5-hydroxyl group of NB-DNJ. This structural similarity with NB-DNJ could be the reason why compound 6 is moderately active. Our results also show that a longer N-alkyl group is important for inhibition of this enzyme by eight-membered analogue N-nonyl-6 and four-membered analogue N-nonyl-25 because the corresponding N-butyl analogues 5 and 24 are inactive compounds. In the overlay shown in Figure 6d, between compound 25 and ceramide, the N-alkyl chain and the N-C2-CH2OH bond of 25 align well with the N-acyl chain and the N-C2-C3-OH bond of ceramide, which could be the reason why this is the most active compound in the series. In case of compound 23, even though the N-alkyl chain and the N-C2-CH2OH bond align with ceramide (picture not shown), the stereochemistry of the 4-hydroxymethyl group seems to prevent inhibition.

When tested for inhibitory activity against β-glucosidase 2, compounds 1, 5, and 22–26 did not show inhibitory activity, whereas compounds 2, 3, 4 and 6 exhibited weak activities. The IC50 values for these compounds are 803, 1123, 904 and 766 µM respectively. The three N-nonyl analogues 2, 4, and 6 were more potent then the corresponding N-butyl derivatives 1, 3, and 5. N-Nonyl-azetidine 27 inhibited rat testicular β-glucosidase 2 at 70 µM, which is similar to the inhibitory activity of the positive control NB-NDJ. This result suggests that the azetidine stereochemistry and a long alkyl chain, such as the nonyl group are important for inhibitory activity. Interestingly, the N-nonylazocane 6 exhibited activities in both the ceramide-specific glucosyltransferase assay and the β-glucosidase assay.

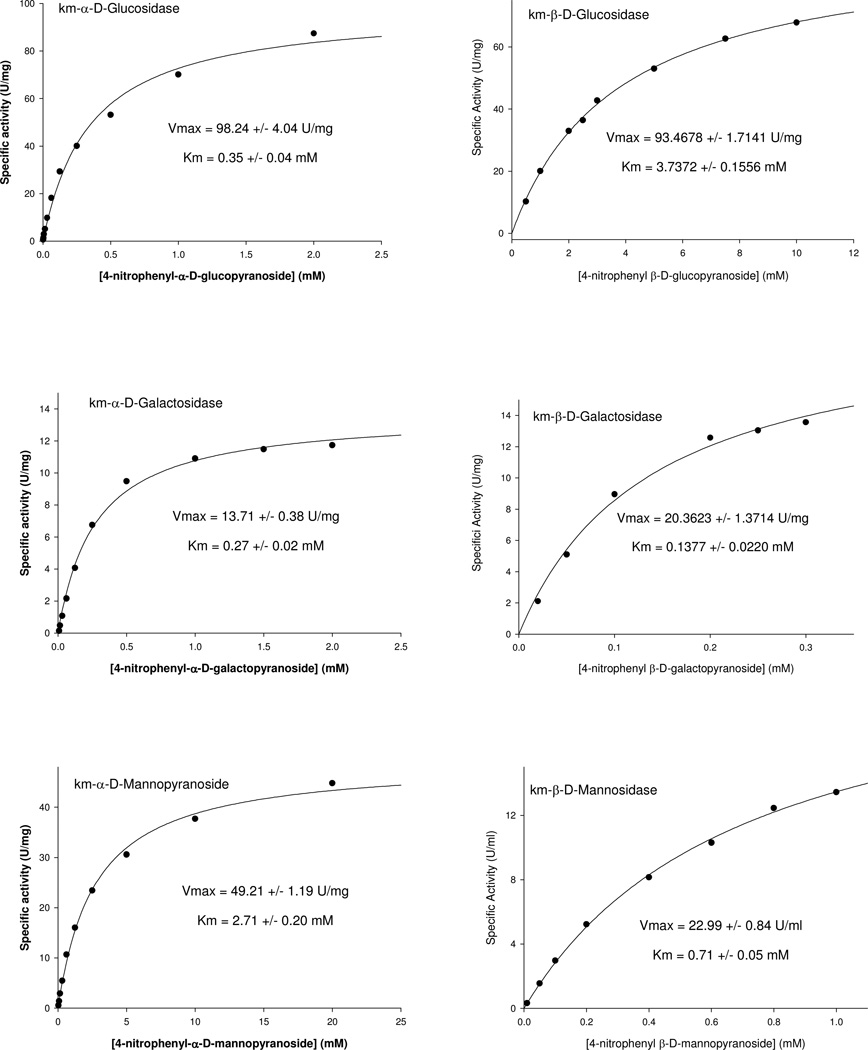

Iminosugars are already used and also hold promise as modulators of carbohydrate-processing enzymes for various therapeutic applications such as Gaucher’s disease, cystic fibrosis, Niemann Pick disease, diabetes, viral disease, Pompe’s disease, Fabry’s disease and Parkinson’s disease.8, 27 In addition, so-called immucillins are in clinical trials for the treatment of T- and B- cell cancers and autoimmune diseases.28 Therefore, we further evaluated the inhibitory properties of the new iminosugars towards other readily available glycosidases (Table 2). The following enzymes were investigated: α-glucosidase (Saccharomyces cerevisiae), β-glucosidase (almond), α-galactosidase (green coffee beans), β-galactosidase (Escherichia coli), α-mannosidase (jack bean) and β-mannosidase (Roman snail). As positive controls for the glycosidase inhibition assays, the following standard compounds were used:29 DNJ (1-deoxynojirimycin) and NB-DNJ (N-butyldeoxynojirimycin) for the α-glucosidase assay; castanospermine for the β-glucosidase assay; DGJ (1-deoxygalactonojirimycin) and NB-DGJ (N-butyldeoxygalactonojirimycin) for the α-galactosidase and β-galactosidase assays; DMJ (1-deoxymannojirimycin) for the α-mannosidase and β-mannosidase assays. The results are summarized in Table 2. In these assays we determined the % remaining activity of the enzymes in the presence of 100 µM of the iminosugars and also their IC50 values (µM).

Table 2.

Glycosidase Inhibitory Activity of Compounds 1–6 and 22–27.a

| glycosidase % remaining activity at 100 µM /IC50 values (µM) |

||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| inhibitor | α-Glc | β-Glc | α-Gal | β-Gal | α-Man | β-Man | ||||||

| % Ra | IC50 | % Ra | IC50 | % Ra | IC50 | % Ra | IC50 | % Ra | IC50 | % Ra | IC50 | |

| DNJ | 34 | 79 | — | — | — | — | — | — | — | — | — | — |

| NB-DNJ | — | 1030 | — | — | — | — | — | — | — | — | — | — |

| Castano. | — | — | 13.5 | 119 | — | — | — | — | — | — | — | — |

| DGJ | — | — | — | — | 0.05 | 0.018 | 23 | 40 | — | — | — | — |

| NB-DGJ | — | — | — | — | — | 10 | 9.6 | 6.0 | — | — | — | — |

| DMJ | — | — | — | — | — | — | — | — | 75 | — | 77 | — |

| 1 | 93 | — | 37 | 87 | 100 | — | 98 | — | 100 | — | 100 | — |

| 2 | 84 | — | 43 | 92 | 100 | — | 92 | — | 100 | — | 93 | — |

| 3 | 81 | — | 52 | 105 | 100 | — | 94 | — | 100 | — | 99 | — |

| 4 | 90 | — | 44 | 134 | 100 | — | 90 | — | 100 | — | 99 | — |

| 5 | 89 | — | 87 | — | 100 | — | 95 | — | 100 | — | 100 | — |

| 6 | 84 | — | 85 | — | 100 | — | 92 | — | 100 | — | 99 | — |

| 22 | 100 | — | 93 | — | 100 | — | 99 | — | 99 | — | 99 | — |

| 23 | 100 | — | 95 | — | 99 | — | 88 | — | 100 | — | 115 | — |

| 24 | 65 | — | 101 | — | 106 | — | 109 | — | 99 | — | 113 | |

| 25 | 0 | 0.6 | 26 | 20 | 66 | — | 107 | — | 92 | — | 76 | — |

| 26 | 90 | — | 82 | — | 98 | — | 96 | — | 98 | — | 95 | — |

| 27 | 100 | — | 95 | — | 57 | — | 99 | — | 99 | — | 106 | — |

The details of the enzyme inhibition study are described in the supporting information; —, not measured; % Ra, % Remaining activity at 100 µM; Castano., Castanospermine.

We found that eight-membered compounds 1–4 were modest inhibitors of β-glucosidase (IC50 = 87–134 µM). Compounds 5 and 6 showed weak inhibition against β-glucosidase (87 and 85% remaining activity at 100 µM). All of the eight-membered compounds showed weak inhibition against α-glucosidase and β-galactosidase (81~98% remaining activity at 100 µM), and little or no inhibitory activity towards α-galactosidase and mannosidases. Even though the activities were moderate or weak, eight-membered iminosugars exhibited specificity for β-glucosidase. When the activities of compounds 1–4 towards β-glucosidase were compared, the length of the N-alkyl group did not show much difference in the activity (IC50 values, 87 versus 92 µM, and 105 versus 134 µM). The four-membered analogues showed specificity towards α-glucosidase and β-glucosidase. Compound 25 was the most potent compound tested. At 100 µM concentration α-glucosidase activity was inhibited completely and only 26% activity of β-glucosidase remained. The IC50 values were 0.6 µM and 20 µM respectively. A similar trend was observed for the inhibition of α- and β-galactosidase by 25 but with greatly reduced inhibitory potency. Compound 24 was a moderate inhibitor of α-glucosidase (65% remaining activity) and compound 27 a moderate inhibitor of α-galactosidase (57% remaining activity). Compound 26 had weak β-glucosidase inhibitory activity (82% remaining activity at 100 µM). Compounds 22 and 23 displayed no inhibitory activities. Of note is the observation that N-nonyl-25 was active in inhibiting α-glucosidase and β-glucosidase activity, whereas the corresponding N-butyl analog 24 did not show significant activity in these assays.

In conclusion, we have designed and synthesized novel eight- and four-membered iminosugars as potential male contraceptive agents. The N-alkyl iminosugar analogues were tested for inhibitory activities against testicular ceramide-specific glucosyltransferase, testicular β-glucosidase 2 and other glycosidases. Among the eight-membered analogues, only the N-nonylpentanol derivative 6 was moderately active against rat-derived ceramide-specific glucosyltransferase. N-Nonylazetidine 27 was the most potent inhibitor of testicular β-glucosidase 2, on par with the positive control NB-DNJ. Unlike NB-DNJ, azetidine 27 is a selective inhibitor of β-glucosidase 2 since this derivative does not inhibit ceramide-specific glucosyltransferase. Compounds 1–4 exhibited modest activity against β-glucosidase from almonds. N-Nonylazetidine 25 was found to be a specific inhibitor of mouse- and rat-derived ceramide-specific glucosyltransferase that did not inhibit testicular β-glucosidase 2. Compound 25 was also an effective inhibitor of α-glucosidase and a moderately active inhibitor of almond β-glucosidase. The studies revealed that penta-hydroxy substitution and the N-nonyl group are important for the activity of the eight-membered analogue 6 for the testis-specific enzymes. In the series of four-membered analogues a stereochemical bias for the meso-25 compound for inhibition of the testis-derived ceramide-specific glucosyltransferases was observed. The N-nonyl group was important for the activity for the two most potent compounds, 6 and 25, because their corresponding N-butyl derivatives 5 and 24 were inactive in all assays.

Experimental Section

General procedures

Commercially available chemicals were used as purchased without further purification. All solvents were dried over an activated alumina column before use except commercially available anhydrous 1,2-dimethoxyethane and 1,2-dichloroethane. All reactions with air- or moisture-sensitive reagents were carried out under a nitrogen atmosphere. The 1H NMR spectra were obtained on a 400 MHz spectrometer. For 1H NMR spectra, the chemical shifts are referenced to the tetramethylsilane (TMS) peak as an internal standard or the residual solvent peak. The 13C NMR spectra were recorded at 100 MHz. Chemical shifts are reported in ppm and were referenced to the appropriate residual solvent peak. High-resolution mass spectra (HRMS) were recorded with electron-spray ionization. IR spectra were taken on a FT-IR spectrometer. Optical rotations were measured on a polarimeter. Flash column chromatography was performed on silica gel (230–400 mesh).

Methyl-6-O-(tert-butyldimethylsilyl)-α-D-glucopyranoside (11)

To a solution of methyl-α-D-glucopyranoside 10 (20.0 g, 102 mmol) in DMF (160 mL) at 0 °C was added imidazole (17.4 g, 256 mmol) followed by tert-butyldimethylsilyl chloride (18.5 g, 123 mmol). The reaction mixture was stirred for 16 h at room temperature. DMF was removed through vacuum distillation and the residue was taken up in EtOAc (1500 mL). The solution was washed with water (3 × 500 mL) and brine (3 x 500 mL), dried over anhydrous Na2SO4, and concentrated under reduced pressure. The residue was purified by silica column chromatography (100% EtOAc) to afford 11 (22.6 g, 72%) as a white solid. 1H NMR (400 MHz, CDCl3)δ 4.65 (d, J = 3.8 Hz, 1H), 3.78 (dd, J = 10.6, 4.9 Hz, 1H), 3.72 (dd, J = 10.6, 4.9 Hz, 1H), 3.63 (td, J = 9.1, 2.6 Hz, 1H), 3.50 (dt, J = 9.8, 4.9 Hz, 1H), 3.42 (m, 2H), 3.32 (s, 3H), 3.19 (d, J = 2.2 Hz, 1H), 3.04 (d, J = 2.6 Hz, 1H), 2.34 (d, J = 9.2 Hz, 1H), 0.81 (s, 9H), 0.00 (s, 6H); 13C NMR (100 MHz, CDCl3)δ 99.1, 74.6, 72.3, 72.1, 70.4, 64.2, 55.3, 25.9, 18.3, −5.4; HRMS (ESI) calcd for [C13H28O6Si + Na]+ 331.1547, found 331.1540. The data are in accordance with reported values.30

Methyl-2,3,4-tri-O-benzyl-6-O-(tert-butyldimethylsilyl)-α-D-glucopyranoside (12)

To a solution of compound 11 (8.00 g, 25.9 mmol) in DMF (90 mL) at 0 °C was added sodium hydride (60% dispersion in mineral oil, 3.84 g, 96.0 mmol) and the mixture was stirred at 0 °C for 30 min. Benzyl bromide (20.0 g, 117 mmol) was added at 0 °C and the mixture was stirred at room temperature for 17 h. The reaction mixture was cooled to 0 °C and MeOH (10 mL) was added dropwise in order to quench excess sodium hydride. The reaction mixture was poured into water (630 mL) and extracted with Et2O (5 × 130 mL). The combined organic layers were washed with water (2 × 250 mL) and brine (2×250 mL), dried over anhydrous Na2SO4, and evaporated under reduced pressure. The residue was purified by silica column chromatography (EtOAc:hexanes 1:12) to afford 12 as a white solid (11 g, 72%). %). mp 77–78 °C; (c 1.00 CHCl3); IR (neat) 3064, 3031, 2928, 2856, ,1949, 1873, 1808, 1748, 1606, 1454, 1360, 1252, 1160, 1092, 1072, 835, 736 cm−1; 1H NMR (400 MHz, CDCl3) δ 7.35–7.20 (m, 15H), 4.93 (d, J = 10.7 Hz, 1H), 4.84 (d, J = 11.2 Hz, 1H), 4.78 (d, J = 10.7 Hz, 1H), 4.75 (d, J = 12.2 Hz, 1H), 4.63 (d, J = 12.2 Hz, 1H), 4.60 (d, J = 11.2 Hz, 1H), 4.57 (d, J = 3.6 Hz, 1H), 3.95 (t, J = 9.2 Hz, 1H), 3.74 (d, J = 3.1 Hz, 2H), 3.58 (dt, J = 9.9, 3.1 Hz, 1H), 3.48 (m, 2H), 3.32 (s, 3H), 0.84 (s, 9H), 0.00 (s, 6H); 13C NMR (100 MHz, CDCl3) δ 138.8, 138.5, 138.3, 128.4, 128.1, 127.8, 127.7, 127.6, 97.9, 82.2, 80.2, 77.8, 75.9, 75.0, 73.4, 71.5, 62.3, 54.9, 25.9, 18.3, −5.2, −5.4; HRMS (ESI) calcd for [C34H46O6Si + Na]+ 601.2956, found 601.2975. The data are in agreement with reported values.31

Methyl-2,3,4-tri-O-benzyl-α-D-glucopyranoside (13)

To a solution of compound 12 (6.62 g, 11.4 mmol) in THF (33 mL) was added tetrabutylammonium fluoride (1M solution in THF, 23 mL, 23 mmol) and the mixture was stirred at room temperature for 16 h. The reaction mixture was quenched with water (10 mL) and then extracted with EtOAc (300 mL). The organic layer was washed with brine (2 × 150 mL), dried over anhydrous Na2SO4, and evaporated under reduced pressure. The crude product was purified by silica column chromatography (EtOAc:hexanes 1:9 and 1:1) to afford compound 13 as a white solid (5.3 g, 99%). 1H NMR (400 MHz, CDCl3) δ 7.38–7.25 (m, 15H), 4.99 (d, J = 10.9 Hz, 1H), 4.88 (d, J = 11.0 Hz, 1H), 4.83 (d, J = 10.9 Hz, 1H), 4.80 (d, J = 12.1 Hz, 1H), 4.66 (d, J = 12.1 Hz, 1H), 4.64 (d, J = 11.0 Hz, 1H), 4.57 (d, J = 3.6 Hz, 1H), 4.00 (t, J = 9.3 Hz, 1H), 3.76 (dd, J = 11.6, 2.5 Hz, 1H), 3.68 (dd, J = 15.8, 4.1 Hz, 1H), 3.65 (m, 1H), 3.51 (m, 2H), 3.36 (s, 3H); 13C NMR (100 MHz, CDCl3) δ 138.7, 138.2, 138.1, 128.5, 128.4, 128.1, 128.0, 127.9, 127.6, 98.2, 82.0, 80.0, 77.4, 75.8, 75.0, 73.4, 70.7, 61.9, 55.2; HRMS (ESI) calcd for [C28H32O6 + Na]+ 487.2091, found 487.2101. The data are in accordance with reported values.20

Methyl-6-deoxy-6-iodo-2,3,4-tri-O-benzyl-α-D-glucopyranoside (14)

To a solution of compound 13 (4.6 g, 9.9 mmol), triphenylphosphine (5.2 g, 20 mmol) and imidazole (3.4 g, 50 mmol) in toluene (70 mL) was added iodine (5.0 g, 20 mmol). The reaction mixture was stirred at 70 °C for 3 h and then cooled to room temperature. The toluene layer was decanted from the resulting solid, which was then washed with EtOAc (100 mL). The combined organic solution was concentrated under reduced pressure. Purification by silica column chromatography (EtOAc:hexanes 1:10 and 1:1) furnished 14 as a white solid (5.4 g, 94%). 1H NMR (400 MHz, CDCl3) δ 7.38–7.26 (m, 15H), 4.99 (d, J = 10.8 Hz, 1H), 4.94 (d, J = 10.9 Hz, 1H), 4.80 (d, J = 10.8 Hz, 1H), 4.79 (d, J = 12.1 Hz, 1H), 4.68 (d, J = 10.9 Hz, 1H), 4.65 (d, J = 12.1 Hz, 1H), 4.61 (d, J = 3.6 Hz, 1H), 4.01 (t, J = 9.3 Hz, 1H), 3.53 (dd, J = 9.6, 3.6 Hz, 1H), 3.45 (m, 2H), 3.42 (s, 3H), 3.33 (t, J = 9.1 Hz, 1H), 3.28 (m, 1H); 13C NMR (100 MHz, CDCl3) δ 138.5, 138.0, 128.5, 128.1, 128.0, 127.9, 127.7, 98.1, 81.6, 81.5, 80.1, 75.8, 75.4, 73.5, 69.3, 55.5, 7.7; HRMS (ESI) calcd for [C28H31IO5 + Na]+ 597.1108, found 597.1127. The data are in accordance with reported values.32

2,3,4-Tri-O-benzyl-5,6-dideoxy-D-xylo-hex-5-enose (9)

To a solution of 14 (5.0 g, 8.7 mmol) in THF/H2O (200 mL/22 mL) was added pre-activated Zn (5.7 g, 87 mmol). The reaction mixture was sonicated at 40 °C until full conversion was observed by TLC. After cooling the reaction mixture to room temperature, Et2O (340 mL) and H2O (130 mL) were added. The resulting mixture was filtered, and the organic layer was separated. The organic layer was washed with H2O (150 mL) and brine (150 mL), dried over anhydrous K2CO3, and evaporated under reduced pressure. The resulting yellow syrup was purified by silica column chromatography (EtOAc:hexanes 1:9 and 1:5) to afford 9 as a colorless oil (3.4 g, 93%). 1H NMR (400 MHz, CDCl3) δ 9.65 (s, 1H), 7.36–7.23 (m, 15H), 5.83 (ddd, J = 16.8, 10.8, 7.7 Hz, 1H), 5.28 (d, J = 10.2 Hz, 1H), 5.27 (d, J = 17.6 Hz, 1H), 4.71 (d, J = 11.8 Hz, 2H), 4.58 (d, J = 11.7 Hz, 1H), 4.54 (d, J = 11.5 Hz, 1H), 4.49 (d, J = 11.8 Hz, 1H), 4.36 (d, J = 11.5 Hz, 1H), 4.15 (dd, J = 7.5, 5.1 Hz, 1H), 3.87 (d, J = 4.4 Hz, 1H), 3.80 (t, J = 4.7 Hz, 1H); 13C NMR (100 MHz, CDCl3) δ 201.6, 137.8, 137.7, 137.2, 134.8, 128.5, 128.4, 128.3, 128.2, 128.1, 127.9, 127.6, 119.4, 82.4, 81.8, 79.9, 74.5, 73.3, 70.9; HRMS (ESI) calcd for [C27H28O4 + K]+ 455.1619, found 455.1837. The data are in accordance with reported values.33

(2S,3S,4R)-N-Allyl-2,3,4-tris(benzyloxy)hex-5-en-1-amine (15)

To a solution of 9 (3.9 g, 9.3 mmol) and allylamine (0.53 g, 9.3 mmol) in 1,2-dichloroethane (40 mL) was added NaBH(OAc)3 (2.7 g, 13 mmol). The reaction mixture was stirred at room temperature for 16 h and quenched by adding aqueous saturated NaHCO3 (100 mL). The mixture was extracted with EtOAc (300 mL) and the organic layer was washed with aqueous saturated NaHCO3 (100 mL). The organic layer was dried over anhydrous MgSO4 and concentrated under reduced pressure. The crude product was purified by silica column chromatography (MeOH:CH2Cl2 1:19) to give 15 as a pale yellow oil (3.6 g, 86%): (c 1.00 CHCl3); IR (neat) 3329, 3064, 3030, 2866, 1642, 1497, 1454, 1351, 1208, 1088, 1068, 995, 922, 735, 687 cm−1; 1H NMR (400 MHz, CDCl3) δ 7.37–7.21 (m, 15H), 5.88 (m, 1H), 5.77 (m, 1H), 5.29 (d, J = 15.4 Hz, 1H), 5.26 (d, J = 12.4 Hz, 1H), 5.07 (dd, J = 17.2, 1.7 Hz, 1H), 5.02 (dd, J = 10.2, 1.4 Hz, 1H), 4.74 (s, 2H), 4.64 (d, J = 11.5 Hz, 1H), 4.63 (d, J = 11.8 Hz, 1H), 4.58 (d, J = 11.5 Hz, 1H), 4.36 (d, J = 11.8 Hz, 1H), 4.03 (dd, J = 7.4, 5.0 Hz, 1H), 3.77 (q, J = 5.6 Hz, 1H), 3.61 (t, J = 5.3 Hz, 1H), 3.05 (m, 2H), 2.70 (dd, J = 12.3, 4.7 Hz, 1H), 2.58 (dd, J = 12.3, 6.5 Hz, 1H); 13C NMR (100 MHz, CDCl3) δ 138.8, 138.6, 138.3, 136.9, 135.6, 128.4, 128.3, 128.2, 128.1,127.9, 127.6, 127.5, 118.6, 115.7, 82.0, 80.6, 79.3, 74.9, 73.1, 70.5, 52.4, 49.0; HRMS (ESI) calcd for [C30H35NO3 + H]+ 458.2690, found 458.2690.

N-Allyl-4-methyl-N-((2S,3S,4R)-2,3,4-tris(benzyloxy)hex-5-enyl)benzenesulfonamide (8a)

A solution of amine 15 (3.5 g, 7.7 mmol), tosyl chloride (1.8 g, 9.3 mmol), DMAP (0.094 g, 0.77 mmol) and triethylamine (1.6 g, 15 mmol) in CH2Cl2 (35 mL) was stirred at room temperature for 3 h. The reaction mixture was then washed with H2O (3x 35 mL) and the combined water layer was back-extracted with CH2Cl2 (2 × 35 mL). The combined organic layer was dried over anhydrous MgSO4 and concentrated under reduced pressure. The residue was purified by silica column chromatography (EtOAc:hexanes 1:9) to give sulfonamide 8a as a colorless oil (4.0 g, 84%). (c 1.00 CHCl3); IR (neat) 3064, 3030, 2868, 1598, 1496, 1454, 1345, 1160, 1090, 930, 736, 698 cm−1; 1H NMR (400 MHz, CDCl3) δ 7.59 (d, J = 8.1 Hz, 2H), 7.35–7.23 (m, 15H), 7.20 (d, J = 8.1 Hz, 2H), 5.84 (ddd, J = 17.3, 10.4, 7.7 Hz, 1H), 5.45 (m, 1H), 5.27 (dd, J = 10.4, 1.6 Hz, 1H), 5.22 (ddd, J = 17.3, 1.6, 0.9 Hz, 1H), 4.99 (dd, J = 3.8, 1.4 Hz, 1H), 4.96 (dd, J = 10.4, 1.4 Hz, 1H), 4.76 (d, J = 11.6 Hz, 1H), 4.69 (d, J = 11.6 Hz, 1H), 4.61 (d, J = 11.6 Hz, 1H), 4.59 (d, J = 11.7 Hz, 1H), 4.55 (d, J = 11.6 Hz, 1H), 4.36 (d, J = 11.7 Hz, 1H), 4.14 (dd, J = 7.7, 5.3 Hz, 1H), 3.99 (dt, J = 7.7, 4.3 Hz, 1H), 3.81(dd, J = 6.4, 1.3 Hz, 2H), 3.56 (t, J = 4.9 Hz, 1H), 3.43 (dd, J = 14.9, 4.2 Hz, 1H), 3.22 (dd, J = 14.9, 7.6 Hz, 1H), 2.40 (s, 3H)); 13C NMR (100 MHz, CDCl3) δ 143.1, 138.5, 138.3, 136.8,135.5, 132.9, 129.6, 128.3, 128.2, 128.0, 127.9, 127.6, 127.5, 127.4, 118.8, 80.7, 80.5, 78.5, 74.1, 73.3, 70.6, 52.5, 48.4, 21.5; HRMS (ESI) calcd for [C37H41NO5S + Na]+ 634.2598, found 634.2600.

(3S,4S,5R,Z)-3,4,5-Tris(benzyloxy)-1-tosyl-1,2,3,4,5,8-hexahydroazocine (7a)

A solution of 8a (3.9 g, 6.3 mmol) and Grubbs catalyst II (0.53 g, 0.63 mmol, 10 mol%) in CH2Cl2 (1600 mL) was refluxed for 1 h. The reaction mixture was concentrated under reduced pressure and the resulting crude product was purified by silica column chromatography (EtOAc:hexanes 1:5) affording 7a as a viscous semisolid (3.1 g, 84%). (c 1.00 CHCl3); IR (neat) 3063, 3029, 2865, 1453, 1347, 1162, 1092, 1070, 738, 698 cm−1; 1H NMR (400 MHz, CDCl3) δ 7.58 (d, J = 8.3 Hz, 2H), 7.35–7.22 (m, 17H), 5.67 (ddd, J = 11.8, 6.5, 1.7 Hz, 1H), 5.45 (br d, J = 11.8 Hz, 1H), 5.00 (t, J = 7.6 Hz, 1H), 4.91 (d, J = 11.1 Hz, 1H), 4.70 (d, J = 11.7 Hz, 1H), 4.66 (d, J = 11.1 Hz, 1H), 4.62 (s, 2H), 4.58 (d, J = 11.7 Hz, 1H), 4.22 (br d, J = 16.4 Hz, 1H), 3,96 (ddd, J = 8.5, 6.8, 3.3 Hz, 1H), 3.60 (dd, J = 14.5, 3.3 Hz, 1H), 3.57 (dd, J = 9.1, 6.8 Hz, 1H), 3.24 (dd, J = 16.4, 4.9 Hz, 1H), 2.87 (dd, J = 14.5, 8.5 Hz, 1H), 2.4 (s, 3H)); 13C NMR (100 MHz, CDCl3) δ 143.7, 138.9, 138.7, 138.6, 134.2, 134.0, 129.8, 128.4, 128.3, 128.0, 127.8, 127.6, 127.5, 127.4, 125.0, 83.5, 81.4, 77.6, 75.3, 73.2, 72.5, 48.9, 48.0, 21.6; HRMS (ESI) calcd for [C35H37NO5S + Na]+ 606.2285, found 606.2277.

tert-Butyl Allyl((2S,3S,4R)-2,3,4-tris(benzyloxy)hex-5-en-1-yl)carbamate (8b)

To a solution of 15 (1.6 g, 3.5 mmol) and Boc anhydride (916 mg, 4.20 mmol) in CH2Cl2 (14 mL) was added DMAP (43 mg, 0.35 mmol). The mixture was stirred at room temperature for 16 h and then concentrated under reduced pressure. The residue was purified by column chromatography (EtOAc:hexanes 1:8) to give 8b (1.56 g, 80%) as a colorless oil. (c 1.00 CHCl3); IR (neat) 3065, 3031, 2977, 1694, 1644, 1455, 1405, 1247, 925, 735 cm−1; 1H NMR (400 MHz, CDCl3) δ 7.35–7.22 (m, 15H), 5.81 (m, 1H), 5.68 (br s, 1H), 5.27 (d, J = 10.8 Hz, 1H), 5.22 (d, J = 17.8 Hz, 1H), 5.04 (d, J = 9.6 Hz, 1H), 4.96 (d, J = 17.1 Hz, 1H), 4.82 (d, J = 11.5 Hz, 1H), 4.67 (d, J = 11.5 Hz, 1H), 4.60 (m, 2H), 4.38 (d, J = 11.8 Hz, 1H), 4.14 (t, J = 6.9 Hz, 1H), 3.91 (dd, J = 9.4, 5.2 Hz, 1H), 3.71 (br s, 2H), 3.48 (dd, J = 6.0, 4.3 Hz, 1H), 3.37 (br s, 2H), 1.44 (s, 9H); 13C NMR (100 MHz, CDCl3) δ 155.6, 138.5, 135.5, 134.0, 128.3, 128.2, 128.0, 127.5, 118.9, 115.9, 81.2, 79.6, 74.2, 73.3, 70.7, 50.9, 47.8, 28.5; HRMS (ESI) calcd for [C35H43NO5 + H]+ 558.3219, found 558.3229.

(5R,6S,7S)-tert-Butyl 5,6,7-Tris(benzyloxy)-5,6,7,8-tetrahydroazocine-1(2H)-carboxylate (7b)

A solution of 8b (100 mg, 0.179 mmol) and Grubbs catalyst II (15 mg, 0.018 mmol, 10 mol%) in CH2Cl2 (45 mL) was refluxed for 4 h. The reaction mixture was concentrated under reduced pressure and the resulting crude product was purified by silica column chromatography (EtOAc:hexaness 1:8) affording 88 mg (92%) of a rotameric mixture of 7b (1:1.4) as a colorless oil. Rotamer A: 1H NMR (400 MHz, CDCl3) δ 7.36–7.23 (m, 15H), 5.66 (m, 2H), 4.84 (d, J = 12.0 Hz, 1H), 4.71–4.50 (m, 5H), 4.47 (m, 1H), 4.17 (d, J = 16.1 Hz, 1H), 3.90 (dd, J = 14.6, 3.0 Hz, 1H), 3.80 (m, 1H), 3.66 (dd, J = 16.6, 4.0 Hz, 1H), 3.60 (dd, J = 9.0, 6.5 Hz, 1H), 3.25 (dd, J = 14.3, 8.3 Hz, 1H), 1.42 (s, 9H); 13C NMR (100 MHz, CDCl3) δ 155.3, 138.7, 138.5, 133.0, 132.8, 128.4, 128.3, 128.2, 127.7, 127.6, 127.5, 127.4, 127.3, 83.8, 79.9, 79.8, 77.5, 75.1, 72.7, 71.9, 46.6, 45.8, 28.4. Rotamer B: 1H NMR (400 MHz, CDCl3) δ 7.36–7.23 (m, 15H), 5.66 (m, 2H), 4.89 (d, J = 11.0 Hz, 1H), 4.71–4.50 (m, 5H), 4.47 (m, 2H), 3.90 (dd, J = 14.6, 3.0 Hz, 1H), 3.80 (m, 1H), 3.60 (dd, J = 9.0, 6.5 Hz, 1H), 3.57 (dd, J = 18.7, 2.6 Hz, 1H), 3.16 (dd, J = 14.7, 8.4 Hz, 1H), 1.46 (s, 9H); 13C NMR (100 MHz, CDCl3) δ 155.5, 138.9, 138.6, 133.0, 132.8, 128.4, 128.3, 128.2, 127.7, 127.6, 127.5, 127.4, 127.3, 83.6, 80.7, 80.5, 77.5, 75.4, 72.9, 71.9, 46.6, 46.5, 28.5. HRMS (ESI) calcd for [C33H39NO5 + Na]+ 552.2720, found 552.2711.

(3S,4S,5R,Z)-3,4,5-Tris(benzyloxy)-1,2,3,4,5,8-hexahydroazocine (16)

A solution of Na metal (405 mg, 17.6 mmol) and naphthalene (2.48 g, 19.4 mmol) in 1,2-dimethoxyethane (18 mL) was stirred at room temperature for 2 h. To a solution of 7a (664 mg, 1.14 mmol) in 1,2-dimethoxyethane (13 mL) at −78 °C was added the Na-naphthalene solution (11.4 mL) dropwise for 30 min. The reaction mixture was stirred at −78 °C for 5 min and then H2O (2.1 mL) was slowly added to the mixture at −78 °C to quench the reaction. The reaction mixture was diluted with Et2O (120 mL), dried over anhydrous MgSO4 and concentrated under reduced pressure. The residue was purified by silica column chromatography (MeOH:CH2Cl2 1: 9) to furnish 16 as a yellowish oil (366 mg, 75%). (c 1.00 CHCl3); IR (neat) 3364, 3063, 3029, 2863, 1496, 1454, 1355, 1207, 1090, 1069, 735, 697 cm−1; 1H NMR (400 MHz, CDCl3) δ 7.37–7.22 (m, 15H), 5.76 (m, 1H), 5.69 (dd, J = 11.7, 6.7 Hz, 1H), 4.77 (m, 1H), 4.74 (d, J = 11.5 Hz, 1H), 4.65 (d, J = 11.5 Hz, 1H), 4.63 (d, J = 11.8 Hz, 1H), 4.59 (d, J = 11.8 Hz, 1H), 4.53 (d, J = 11.8 Hz, 1H), 4.49 (d, J = 11.8 Hz, 1H), 3.71 (dd, J = 7.4, 5.4 Hz, 1H), 3.57 (m, 1H), 3.44 (dd, J = 16.8, 4.8 Hz, 1H), 3.29 (ddd, J = 16.8, 5.2, 1.5 Hz, 1H), 3.06 (m, 2H)); 13C NMR (100 MHz, CDCl3) δ 138.7,138.6, 138.5, 132.9, 130.0, 128.4, 128.3, 128.1, 127.7, 127.6, 127.5, 84.0, 79.9, 78.2, 74.2, 72.3, 71.7, 48.1, 47.8; HRMS (ESI) calcd for [C28H31NO3 + Na]+ 452.2196, found 452.2209. Compound 16 was also obtained from 7b. Compound 7b (20 mg, 0.038 mmol) was dissolved with 4N-HCl in dioxane (118 µL, 0.47 mmol). The solution was stirred at room temperature for 1 h. Excess HCl and dioxane were removed by evaporation. Conc. NH4OH (60 µL) and H2O (300 µL) were added to the concentrated mixture. The mixture was extracted with CH2Cl2 (3×2 mL), dried over anhydrous MgSO4 and concentrated under reduced pressure. The crude product was purified by silica column chromatography (MeOH: CH2Cl2 1:9) to give 16 as a yellowish oil (14 mg, 85%). All the spectra are identical with the ones of compound 16 obtained from compound 7a.

(3S,4S,5R,Z)-3,4,5-Tris(benzyloxy)-1-butyl-1,2,3,4,5,8-hexahydroazocine (17a)

To a solution of 16 (200 mg, 0.47 mmol) and butyraldehyde (40 µL, 0.45 mmol) in 1,2-dichloroethane (2 mL) at room temperature was added NaBH(OAc)3 (140 mg, 0.65 mmol). The reaction mixture was stirred at room temperature for 16 h, diluted with EtOAc (16 mL), washed with saturated NaHCO3 (2 × 4 mL), dried over anhydrous MgSO4 and concentrated under reduced pressure. The crude product was purified by silica column chromatography (EtOAc:hexanes 1:3) to give 17a as a yellowish oil (170 mg, 75%). (c 1.0 CHCl3); IR (neat) 3063, 3029, 2930, 2861, 1496, 1454, 1358, 1207, 1091, 1068, 734, 697 cm−1; 1H NMR (400 MHz, CDCl3) δ 7.36–7.22 (m, 15H), 5.57 (ddd, J = 11.9, 5.7, 1.6 Hz, 1H), 5.50 (br d, J = 11.7 Hz, 1H), 5.18 (br s, 1H), 4.94 (d, J = 10.7 Hz, 1H), 4.69 (d, J = 11.3 Hz, 1H), 4.68 (d, J = 10.7 Hz, 1H), 4.66 (d, J = 11.3 Hz, 1H), 4.59 (d, J = 11.6 Hz, 1H), 4.58 (d, J = 11.6 Hz, 1H), 3.54 (m, 2H), 3.25 (br d, J = 16.4 Hz, 1H), 2.97 (dd, J = 16.4, 3.6 Hz, 1H), 2.76 (dd, J = 13.8, 8.9 Hz, 1H), 2.57 (d, J = 13.8 Hz, 1H), 2.37 (m, 2H), 1.35 (m, 2H), 1.24 (sex, J = 7.2 Hz, 2H), 0.86 (t, J = 7.3 Hz, 3H); 13C NMR (100 MHz, CDCl3) δ 139.3, 139.2, 138.9, 133.1, 128.8, 128.3, 128.2, 127.9, 127.7, 127.5, 127.4, 127.2, 85.1, 81.4, 78.2, 75.7, 72.9, 71.9, 57.7, 55.1, 55.0, 30.0, 20.5, 14.0; HRMS (ESI) calcd for [C32H39NO3 + H]+ 486.3003, found 486.3020.

(3S,4S,5R,Z)-3,4,5-Tris(benzyloxy)-1-nonyl-1,2,3,4,5,8-hexahydroazocine (17b)

To a solution of 16 (220 mg, 0.51 mmol) and nonyl aldehyde (85 µL, 0.49 mmol) in 1,2-dichloroethane (2 mL) at room temperature was added NaBH(OAc)3 (152 mg, 0.717 mmol). The reaction mixture was stirred at room temperature for 16 h, diluted with EtOAc (18 mL), washed with saturated NaHCO3 (2 × 5 mL), dried over anhydrous MgSO4 and concentrated under reduced pressure. The crude product was purified by silica column chromatography (EtOAc:hexanes 1:4) to give 17b as a yellowish oil (217 mg, 76%). (c 1.0 CHCl3); IR (neat) 3063, 3030, 2926, 2855, 1496, 1454, 1357, 1207, 1092, 1068, 733, 697 cm−1; 1H NMR (400 MHz, CDCl3) δ 7.38–7.22 (m, 15H), 5.57 (dd, J = 11.5, 5.5 Hz, 1H), 5.50 (br d, J = 11.8 Hz, 1H), 5.18 (br s, 1H), 4.94 (d, J = 10.7 Hz, 1H), 4.69 (d, J = 11.4 Hz, 1H), 4.68 (d, J = 10.7 Hz, 1H), 4.65 (d, J = 11.4 Hz, 1H), 4.59 (d, J = 11.6 Hz, 1H), 4.58 (d, J = 11.6 Hz, 1H), 3.53 (m, 2H), 3.25 (br d, J = 16.4 Hz, 1H), 2.97 (dd, J = 16.5, 3.8 Hz, 1H), 2.76 (dd, J = 13.9, 8.9 Hz, 1H), 2.58 (d, J = 13.9 Hz, 1H), 2.37 (m, 2H), 1.42–1.15 (br m, 14H), 0.87 (t, J = 6.8 Hz, 3H); 13C NMR (100 MHz, CDCl3) δ 139.2, 138.8, 133.1, 128.7, 128.3, 128.2, 127.8, 127.7, 127.5, 127.4, 127.2, 85.1, 81.4, 78.3, 75.6, 72.9,?72.0, 58.0, 55.1, 54.9, 31.9, 29.6, 29.3, 27.8, 27.4, 22.7, 14.1; HRMS (ESI) calcd for [C37H49NO3 + H]+ 556.3785, found 556.3804.

(3S,4S,5R)-1-Butylazocane-3,4,5-triol (1)

To a solution of 17a (80 mg, 0.17 mmol) in MeOH (5 mL) was added PdCl2 (20 mg, 0.12 mmol). The reaction mixture was stirred under H2 atmosphere at room temperature for 16 h. The reaction mixture was filtered through Celite and concentrated under reduced pressure. The residue was purified by SPE-amine column chromatography (MeOH:CH2Cl2 1:100 to 1:50 gradient) to furnish 1 as a colorless thick oil (27 mg, 76%). (c 1.04 MeOH); IR (neat) 3363, 2929, 2863, 1653, 1456, 1364, 1102, 1035, 943 cm−1; 1H NMR (400 MHz, CD3OD) δ 3.89 (dd, J = 8.4, 3.3 Hz, 1H), 3.72 (td, J = 9.6, 5.8 Hz, 1H), 3.44 (dd, J = 9.1, 3.3 Hz, 1H), 2.66–2.45 (m, 6H), 1.92–1.74 (m, 3H), 1.59 (m, 1H), 1.50 (quin, J = 7.4 Hz, 2H), 1.36 (m, 2H), 0.95 (t, J = 7.3 Hz, 3H); 13C NMR (100 MHz, CD3OD) δ 80.6, 71.9, 71.8, 60.1, 60.0, 53.7, 30.8, 27.8, 25.9, 21.6, 14.3; HRMS (ESI) calcd for [C11H23NO3 + H]+ 218.1751, found 218.1753.

(3S,4S,5R)-1-Nonylazocane-3,4,5-triol (2)

To a solution of 17b (70 mg, 0.13 mmol) in MeOH (4 mL) was added PdCl2 (16 mg, 0.088 mmol). The reaction mixture was stirred under H2 atmosphere at room temperature for 16 h. The reaction mixture was filtered through Celite and concentrated under reduced pressure. The residue was purified by SPE-amine column chromatography (MeOH:CH2Cl2 1:100 to 1:50 gradient) to furnish 2 as a colorless thick oil (28 mg, 78%). (c 1.03 MeOH); IR (neat) 3392, 2923, 2854, 1647, 1468, 1364, 1105, 1039, 950 cm−1 ; 1H NMR (400 MHz, CD3OD) δ 3.79 (dd, J = 8.2, 3.3 Hz, 1H), 3.62 (td, J = 9.6, 5.7 Hz, 1H), 3.34 (dd, J = 9.0, 3.3 Hz, 1H), 2.56–2.35 (m, 6H), 1.82–1.64 (m, 3H), 1.49 (m, 1H), 1.42 (m, 2H), 1.23 (br s, 12H), 0.81 (t, J = 6.8 Hz, 3H); 13C NMR (100 MHz, CD3OD) δ 80.6, 72.0, 71.8, 60.5, 60.0, 53.8, 33.0, 30.6, 30.4, 28.6, 28.4, 27.9, 25.9, 23.7, 14.4; HRMS (ESI) calcd for [C16H33NO3 + H]+ 288.2533, found 288.2535.

(3S,4S,5R,Z)-1-Butyl-1,2,3,4,5,8-hexahydroazocine-3,4,5-triol (3)

To liquid ammonia (24 mL) at −78 °C was added granular Li metal (91 mg, 13 mmol). The solution was stirred at −78 °C for 20 min. A solution of 17a (80 mg, 0.16 mmol) in THF (4 mL) was added slowly to the Li-ammonia solution at −78 °C and then the reaction mixture was stirred at −78 °C for 1 h. Liquid ammonia was removed by nitrogen purge at −78 °C. When most ammonia was removed, MeOH (30 mL) containing 4 drops of H2O was added to the residue at −78 °C to quench the reaction. After stirring at −78 °C for 20 min, the mixture was evaporated under reduced pressure. The residue was dissolved in MeOH/CH2Cl2 (2:8, 5 mL) and filtered through Celite. The filtered solution was concentrated in vacuo and purified by SPE-amine column chromatography (MeOH:CH2Cl2 0.5:100 to 4:100 gradient) to furnish 3 as a colorless thick oil (21 mg, 59%). (c 1.04 MeOH); IR (neat) 3370, 3020, 2957, 2932, 2871, 1655, 1458, 1377, 1039, 968, 725 cm−1; 1H NMR (400 MHz, CD3OD) δ 5.86 (m, 1H), 5.71 (dt, J = 12.2, 3.5 Hz, 1H), 4.18 (br s, 1H), 3.71 (m, 1H), 3.46 (dd, J = 8.5, 3.7 Hz, 1H), 3.38 (br d, J = 17.5 Hz, 1H), 3.04 (br d, J = 18.5 Hz, 1H), 2.81 (t, J = 11.6 Hz, 1H), 2.54 (m, 3H), 1.52 (quin, J = 7.5 Hz, 2H), 1.36 (sex, J = 7.4 Hz, 2H), 0.95 (t, J = 7.3 Hz, 3H); 13C NMR (100 MHz, CD3OD) δ 132.9, 130.3, 80.7, 72.3, 70.9, 60.9, 59.3, 56.5, 30.3, 21.6, 14.2; HRMS (ESI) calcd for [C11H21NO3 + Na]+ 238.1414, found 238.1423.

(3S,4S,5R,Z)-1-Nonyl-1,2,3,4,5,8-hexahydroazocine-3,4,5-triol (4)

To liquid ammonia (21 mL) at −78 °C was added granular Li metal (80 mg, 12 mmol). The solution was stirred at −78 °C for 20 min. A solution of 17b (80 mg, 0.14 mmol) in THF (4 mL) was added slowly to the Li-ammonia solution at −78 °C and then the reaction mixture was stirred at −78 °C for 1 h. Liquid ammonia was removed by nitrogen purge at −78 °C. When most ammonia was removed, MeOH (30 mL) containing 5 drops of H2O was added to the residue at −78 °C to quench the reaction. After stirring at −78 °C for 20 min, the mixture was evaporated under reduced pressure. The residue was dissolved in MeOH/CH2Cl2 (1:9, 5 mL) and filtered through Celite. The filtered solution was concentrated in vacuo and purified by SPE-amine column chromatography (MeOH:CH2Cl2 0.5:100 to 4:100 gradient) to furnish 4 as a semisolid (27 mg, 66%). (c 1.05 MeOH); IR (neat) 3408, 3226, 2921, 2853, 1660, 1486, 1459, 1360, 1294, 1074, 1039, 974, 715 cm−1 ; 1H NMR (400 MHz, CD3OD) δ 5.77 (m, 1H), 5.61 (dt, J = 12.3, 3.5 Hz, 1H), 4.08 (br s, 1H), 3.61 (m, 1H), 3.36 (dd, J = 8.4, 3.7 Hz, 1H), 3.28 (br d, J = 18.1 Hz, 1H), 2.94 (br d, J = 18.5 Hz, 1H), 2.71 (t, J = 11.6 Hz, 1H), 2.44 (m, 3H), 1.44 (br t, J = 6.9 Hz, 2H), 1.23 (br s,12H), 0.81 (t, J = 6.8 Hz, 3H); 13C NMR (100 MHz, CD3OD) δ 133.0, 130.3, 80.7, 72.3, 70.9, 60.9, 59.7, 56.6, 33.0, 30.6, 30.4, 28.4, 28.1, 23.7, 14.4; HRMS (ESI) calcd for [C16H31NO3 + Na]+ 308.2196, found 308.2194.

(3R,4R,5R,6R,7S)-5,6,7-Tris(benzyloxy)-1-tosylazocane-3,4-diol (18)

To a solution of 7a (300 mg, 0.514 mmol) in THF/ t-BuOH/ H2O (3 mL/9 mL/9 mL) were added K2CO3 (213 mg, 1.54 mmol), K3(FeCN)6 (508 mg, 1.54 mmol), (DHQ)2-PHAL (40 mg, 0.051 mmol). The mixture was stirred at 0 °C for 5 min and then to the solution were added CH3SO2NH2 (98 mg, 1.0 mmol) and K2OsO2(OH)4 (4 mg, 0.01 mmol). After the reaction mixture had been stirred at room temperature for 40 h, Na2SO3 (780 mg, 6.2 mmol) was added for quenching and the mixture was stirred for 40 min. The mixture was diluted with H2O (25 mL) and extracted with EtOAc (4 × 75 mL). The organic layer was washed with 2N-KOH (120 mL), dried over anhydrous MgSO4 and concentrated under reduced pressure. The residue was purified by silica column chromatography (EtOAc:hexanes 1:1) to give 18 as a white foam (260 mg, 82%). (c 1.00 MeOH); IR (neat) 3392, 3063, 3030, 2924, 1598, 1496, 1454, 1344, 1160, 1089, 1072, 908, 816, 726, 699 cm−1; 1H NMR (400 MHz, CDCl3) δ 7.66 (d, J = 8.3 Hz, 2H), 7.37–7.23 (m, 15H), 7.16 (m, 2H), 4.78 (d, J = 11.8 Hz, 1H), 4.68 (d, J = 11.1 Hz, 1H), 4.62 (d, J = 11.1 Hz, 1H), 4.56 (d, J = 11.8 Hz, 1H), 4.44 (d, J = 11.1 Hz, 1H), 4.38 (d, J = 11.1 Hz, 1H), 4.38 (d, J = 8.0 Hz, 1H), 4.16–4.01 (m, 3H), 3.99–3.91 (m, 2H), 3.68 (q, J = 4.0 Hz, 1H), 3.39 (dd, J = 14.8, 5.0 Hz, 1H), 2.96 (dd, J = 14.8, 10.7 Hz, 1H), 2.82 (dd, J = 13.8, 3.0 Hz, 1H), 2.67 (d, J = 9.0 Hz, 1H), 2.43 (s, 3H); 13C NMR (100 MHz, CDCl3) δ 143.8, 138.3, 138.0, 135.7, 134.1, 129.8, 128.8, 128.6, 128.4, 128.3, 128.0, 127.8, 127.7, 127.5, 83.8, 80.7, 79.4, 74.9, 74.6, 73.8, 73.6, 71.8, 48.2, 47.4, 21.6; HRMS (ESI) calcd for [C35H39NO7S + Na]+ 640.2345, found 640.2348.

(3S,4R,5S,6R,7R)-3,4,5,6,7-Pentakis(benzyloxy)-1-tosylazocane (19)

To a solution of 18 (700 mg, 1.1 mmol) in dry DMF (4.2 mL) at 0 °C were added sodium hydride (60% dispersion in mineral oil, 159 mg, 3.97 mmol) and benzyl bromide (582 mg, 3.40 mmol). The reaction mixture was stirred at room temperature for 15 h and then quenched with MeOH (20 drops). The reaction mixture was diluted with H2O (42 mL) and extracted with EtOAc (4 × 80 mL). The organic layer was washed with H2O (160 mL) and brine (2 × 160 mL), dried over anhydrous MgSO4, and concentrated under reduced pressure. The crude product was purified by silica column chromatography (EtOAc:hexanes 1:5) to afford 19 as a colorless thick oil (787 mg, 87%). (c 1.00 CHCl3); IR (neat) 3063, 3030, 2930, 2869, 1598, 1496, 1454, 1346, 1161, 1089, 912, 816, 737, 698 cm−1; 1H NMR (400 MHz, CDCl3) δ 7.52 (d, J = 8.3 Hz, 2H), 7.37–7.19 (m, 27H), 4.91 (d, J = 10.6 Hz, 1H), 4.82 (d, J = 11.5 Hz, 1H), 4.81 (d, J = 11.8 Hz, 1H), 4.79 (d, J = 11.9 Hz, 1H), 4.75 (d, J = 10.6 Hz, 1H), 4.74 (d, J = 11.5 Hz, 1H), 4.71 (d, J = 11.8 Hz, 1H), 4.47 (d, J = 11.9 Hz, 1H), 4.33 (d, J = 11.8 Hz, 1H), 4.28 (d, J = 11.8 Hz, 1H), 4.22 (s, 1H), 4.01 (m, 2H), 3.82 (d, J = 8.1 Hz, 1H), 3.60 (dd, J = 13.8, 5.0 Hz, 1H), 3.49–3.41 (m, 2H), 3.11 (dd, J = 15.1, 10.1 Hz, 1H), 2.82 (dd, J = 13.8, 10.7 Hz, 1H), 2.40 (s, 3H); 13C NMR (100 MHz, CDCl3) δ 143.7, 139.2, 139.0, 138.9, 138.2, 134.8, 129.8, 128.4, 128.3, 128.2, 128.0, 127.9, 127.7, 127.6, 127.5, 127.3, 127.2, 83.9, 83.8, 83.2, 81.8, 81.6, 76.2, 74.7, 74.2, 73.8, 71.9, 51.8, 50.2, 21.5; HRMS (ESI) calcd for [C49H51NO7S + Na]+ 820.3278, found 820.3307.

(3S,4R,5S,6R,7R)-3,4,5,6,7-Pentakis(benzyloxy)azocane (20)

A solution of Na metal (583 mg, 25.4 mmol) and naphthalene (3.58 g, 27.9 mmol) in 1,2-dimethoxyethane (25 mL) was stirred at room temperature for 2 h. To a solution of 19 (763 mg, 0.956 mmol) in 1,2-dimethoxyethane (11 mL) at −78 °C was added the Na-naphthalene solution (3.8 mL) dropwise for 20 min. After the reaction mixture was stirred at −78 °C for 10 min, H2O (1.5 mL) with Et2O (10 mL) and 1,2-dimethoxyethane (2 mL) was slowly added to the mixture at −78 °C to quench the reaction. The slurry was stirred at −78 °C until the green color disappeared. The reaction mixture was diluted with Et2O (120 mL), dried over anhydrous MgSO4 and concentrated under reduced pressure. The residue was purified by silica column chromatography (MeOH:CH2Cl2 1: 13) to furnish 20 as a yellowish oil (440 mg, 72%). (c 1.0 CHCl3); IR (neat) 3384, 3063, 3030, 2868, 1496, 1454, 1362, 1208, 1092, 1072, 736 cm−1; 1H NMR (400 MHz, CDCl3) δ 7.42–7.20 (m, 25H), 4.85–4.67 (m, 6H), 4.60 (d, J = 11.6 Hz, 1H), 4.58 (d, J = 11.6 Hz, 1H), 4.39 (d, J = 12.0 Hz, 1H), 4.34 (d, J = 12.0 Hz, 1H), 4.09 (br s, 1H), 3.96 (t, J = 8.1 Hz, 1H), 3.84 (d, J = 7.8 Hz, 1H), 3.44–3.36 (m, 2H), 3.09–2.99 (m, 2H), 2.92 (dd, J = 14.6, 10.1 Hz, 1H), 2.85 (dd, J = 13.9, 4.4 Hz, 1H); 13C NMR (100 MHz, CDCl3) δ 139.1, 139.0, 138.9,138.7, 138.6, 128.3, 128.2, 128.0,127.8, 127.6, 127.5, 127.4, 83.5, 83.3, 82.7, 82.2, 81.6, 75.5, 74.3, 73.5, 73.4, 71.5, 50.0, 48.3; HRMS (ESI) calcd for [C42H45NO5 + H]+ 644.3370, found 644.3386.

(3S,4R,5S,6R,7R)-3,4,5,6,7-Pentakis(benzyloxy)-1-butylazocane (21a)

To a solution of 20 (204 mg, 0.317 mmol) and butyraldehyde (27 µL, 0.30 mmol) in 1,2-dichloroethane (1.5 mL) at room temperature was added NaBH(OAc)3 (94 mg, 0.44 mmol). The reaction mixture was stirred at room temperature for 16 h, diluted with EtOAc (30 mL) and washed with saturated NaHCO3 (2×10 mL). The organic layer was dried over anhydrous MgSO4 and concentrated under reduced pressure. The crude product was purified by silica column chromatography (first purification EtOAc:hexanes 1:1, second purification MeOH:CH2Cl2 1:18) to give 21a as a yellowish oil (175 mg, 79%). (c 1.00 CHCl3); IR (neat) 3063, 3030, 2930, 2862, 1679, 1496, 1454, 1360, 1206, 1072, 735, 698 cm−1; 1H NMR (400 MHz, CDCl3) δ 7.43–7.20 (m, 25H), 4.94 (d, J = 10.3 Hz, 1H), 4.88 (d, J = 12.1 Hz, 1H), 4.81 (d, J = 12.1 Hz, 1H), 4.79 (d, J = 12.1 Hz, 1H), 4.74 (d, J = 10.3 Hz, 1H), 4.70 (d, J = 11.6 Hz, 1H), 4.57 (d, J = 11.6 Hz, 1H), 4.49 (d, J = 12.1 Hz, 1H), 4.30 (d, J = 12.1 Hz, 1H), 4.22 (s, 1H), 4.19 (d, J = 12.1 Hz, 1H), 4.09 (t, J = 8.8 Hz, 1H), 3.88 (d, J = 9.4 Hz, 1H), 3.33 (ddd, J = 10.6, 8.0, 2.8 Hz, 1H), 3.12–3.01 (m, 2H), 2.79 (dd, J = 13.2, 10.8 Hz, 1H), 2.64 (dd, J = 14.7, 3.2 Hz, 1H), 2.59 (dd, J = 13.6, 5.7 Hz, 1H), 2.42 (m, 1H), 2.25 (m, 1H), 1.17 (br m, 4H), 0.83 (t, J = 7.0 Hz, 3H); 13C NMR (100 MHz, CDCl3) δ 139.4, 139.1, 138.9, 138.6, 128.4, 128.3, 128.2, 128.1, 128.0, 127.9, 127.5, 127.4, 127.3, 84.0, 83.4, 82.3, 81.9, 76.4, 74.2, 74.0, 73.1, 71.1, 57.8, 57.7, 55.1, 30.5, 20.4, 14.1; HRMS (ESI) calcd for [C46H53NO5 + H]+ 700.3996, found 700.4004.

(3S,4R,5S,6R,7R)-3,4,5,6,7-Pentakis(benzyloxy)-1-nonylazocane (21b)

To a solution of 20 (198 mg, 0.308 mmol) and nonyl aldehyde (51 µL, 0.30 mmol) in 1,2-dichloroethane (1.5 mL) at room temperature was added NaBH(OAc)3 (91 mg, 0.43 mmol). The reaction mixture was stirred at room temperature for 16 h, diluted with EtOAc (30 mL) and washed with saturated NaHCO3 (2×10 mL). The organic layer was dried over anhydrous MgSO4 and concentrated under reduced pressure. The crude product was purified by silica column chromatography (first purification EtOAc:hexanes 1:1, second purification MeOH:CH2Cl2 1:16) to give 21b as a yellowish oil (200 mg, 84%). (c 1.00 CHCl3); IR (neat) 3063, 3030, 2925, 2854, 1681, 1496, 1454, 1359, 1206, 1067, 912, 733, 696 cm−1; 1H NMR (400 MHz, CDCl3) δ 7.44–7.13 (m, 25H), 4.93 (d, J = 10.3 Hz, 1H), 4.88 (d, J = 12.1 Hz, 1H), 4.81 (d, J = 12.1 Hz, 1H), 4.79 (d, J = 12.0 Hz, 1H), 4.74 (d, J = 10.3 Hz, 1H), 4.70 (d, J = 11.6 Hz, 1H), 4.58 (d, J = 11.6 Hz, 1H), 4.48 (d, J = 12.0 Hz, 1H), 4.29 (d, J = 12.1 Hz, 1H), 4.22 (s, 1H), 4.19 (d, J = 12.1 Hz, 1H), 4.08 (t, J = 8.8 Hz, 1H), 3.88 (d, J = 9.4 Hz, 1H), 3.33 (ddd, J = 10.5, 8.1, 2.6 Hz,1H), 3.14–3.00 (m, 2H), 2.79 (dd, J = 13.2, 10.8 Hz, 1H), 2.64 (dd, J = 14.7, 2.7 Hz, 1H), 2.60 (dd, J = 13.2, 5.3 Hz, 1H), 2.41 (m, 1H), 2.25 (m, 1H), 1.36–1.07 (br m, 14H), 0.89 (t, J = 6.8 Hz, 3H); 13C NMR (100 MHz, CDCl3) δ 139.4, 139.3, 139.0, 138.8, 138.6, 128.4, 128.3, 128.2, 128.0, 127.9, 127.5, 127.4, 127.3, 83.9, 83.4, 82.3, 82.1, 74.3, 73.9, 73.1, 71.1, 58.1, 57.6, 55.1, 31.9, 29.7, 29.6, 29.4, 28.3, 27.3, 22.7, 14.2; HRMS (ESI) calcd for [C51H63NO5 + H]+ 770.4779, found 770.4770.

(3S,4R,5S,6R,7R)-1-Butylazocane-3,4,5,6,7-pentaol (5)

To a solution of 21a (164 mg, 0.234 mmol) in MeOH (6 mL) was added PdCl2 (33 mg, 0.19 mmol). The reaction mixture was stirred under H2 atmosphere at room temperature for 18 h. The reaction mixture was filtered through Celite and concentrated under reduced pressure. The residue was purified by SPE-amine column chromatography (MeOH:CH2Cl2 1:9 and 1:5) to afford 5 as a semisolid (47 mg, 80%). (c 0.932 MeOH); IR (neat) 3403, 3356, 2947, 2872, 2807, 1683, 1469, 1398, 1105, 1040 cm−1; 1H NMR (400 MHz, CD3OD) δ 3.89 (m, 3H), 3.63 (td, J = 8.3, 6.1 Hz, 1H), 3.57 (dd, J = 8.5, 4.2 Hz, 1H), 2.84 (dd, J = 14.8, 5.2 Hz, 1H), 2.73 (dd, J = 14.8, 2.7 Hz, 1H), 2.67 (d, J = 6.1 Hz, 1H), 2.67 (d, J = 8.3 Hz, 1H), 2.59 (t, J = 7.7 Hz, 2H), 1.54 (m, 2H), 1.34 (sex, J = 7.4 Hz, 2H), 0.95 (t, J = 7.3 Hz, 3H); 13C NMR (100 MHz, CD3OD) δ 79.9, 78.6, 74.3, 73.4, 72.6, 60.9, 59.3, 57.1, 30.4, 21.6, 14.3; HRMS (ESI) calcd for [C11H23NO5 + H]+ 250.1649, found 250.1644.

(3S,4R,5S,6R,7R)-1-Nonylazocane-3,4,5,6,7-pentaol (6)

To a solution of 21b (19 mg, 0.025 mmol) in MeOH (0.8 mL) was added PdCl2 (4 mg, 0.02 mmol). The reaction mixture was stirred under H2 atmosphere at room temperature for 18 h. The reaction mixture was filtered through Celite and concentrated under reduced pressure. The residue was purified by silica column chromatography (MeOH:CH2Cl2 1:5 and 1:3) followed by SPE-C18 column chromatography (MeOH:H2O 2:8 to 9:1 gradient) to afford 6 as a semisolid (5.3 mg, 74%). (c 1.04 MeOH); IR (neat) 3370, 3311, 2921, 2852, 1680, 1467, 1106, 1035 cm−1; 1H NMR (400 MHz, CD3OD) δ 3.90 (m, 3H), 3.62 (td, J = 8.2, 6.0 Hz, 1H), 3.58 (dd, J = 8.4, 4.2 Hz, 1H), 2.84 (dd, J = 14.8, 5.3 Hz, 1H), 2.73 (dd, J = 14.8, 2.7 Hz, 1H), 2.68 (d, J = 6.0 Hz, 1H), 2.67 (d, J = 8.2 Hz, 1H), 2.59 (t, J = 7.7 Hz, 2H), 1.55 (m, 2H), 1.32 (brs, 12H), 0.91 (t, J = 6.8 Hz, 3H); 13C NMR (100 MHz, CD3OD) δ 79.7, 78.3, 73.8, 73.2, 72.4, 61.2, 59.1, 57.0, 33.1, 30.7, 30.6, 30.5, 28.3, 28.0, 23.8, 14.5; HRMS (ESI) calcd for [C16H33NO5 + H]+ 320.2431, found 320.2428.

(R,E)-3-(2,2-Dimethyl-1,3-dioxolan-4-yl)prop-2-en-1-ol (29)

L-Glyceraldehyde acetonide (28) was obtained from of L-gulono-1,4-lactone as described in the literature.34,35 The aldehyde 28 (3.07 g, 23.6 mmol) in benzene, was added to a refluxing solution of (carbethoxymethylene)triphenylphosphorane (12.3 g, 35.4 mmol) in benzene (35 mL) via cannula. The reaction mixture was refluxed overnight and cooled to room temperature. Benzene was evaporated under reduced pressure and the resulting residue was triturated with Et2O to separate the insoluble triphenylphosphine oxide. The ether portions were combined and concentrated. The crude product was then purified by flash silica gel column chromatography on silica gel using hexanes: EtOAc (9:1) to afford 3.5 g (74%) of the E-isomer and 0.4 g (8%) of the Z-isomer. To a solution of the E-ester (3.5 g, 17.5 mmol) in anhydrous CH2Cl2 (100 mL) was added dropwise DIBAL-H (1 M solution in hexanes, 38.5 mmol, 38.5 mL) at −78 °C. The solution was stirred for 1 h at the same temperature and allowed to warm to 0 °C. After completion of the reaction, (monitored by TLC), methanol was added slowly (about 2 mL) followed by addition of a cold aqueous saturated potassium tartrate solution. The biphasic mixture was stirred for 2 h and extracted with EtOAc. The combined organic extracts were dried over anhydrous sodium sulfate and purified by column chromatography to give 2.5 g (93%) in 69% overall yield of the allylic alcohol 29 as a colorless oil. (c 1.01, MeOH); 1H NMR (400 MHz, CDCl3) δ 5.90 (td, J = 5.0, 15.5 Hz, 1H), 5.67 (dd, J = 7.4, 15.5 Hz, 1H), 4.52 (q, J = 7.1 Hz, 1H), 4.07 (d, J = 6.1 Hz, 3H), 3.85 (s, 1H), 3.57 (t, J = 7.9 Hz, 1H), 1.41 (s, 3H), 1.37 (s, 3H); 13C NMR (100 MHz, CDCl3) δ 133.7, 127.8, 109.3, 76.5, 69.3, 61.9, 26.6, 25.8; HRMS (ESI+, M + Na) m/z calcd for [C8H14NaO3+] 181.0841, found 181.0839.

(S)-4-((2R,3S)-3-(Benzyloxymethyl)oxiran-2-yl)-2,2-dimethyl-1,3-dioxolane (30)

To a −40 °C suspension of titanium isopropoxide (0.38 mL, 1.30 mmol) and powdered, activated 3 Å molecular sieves (1 g) in CH2Cl2 (5 mL) was added a solution of (+)-diisopropyl tartrate (0.303 mL, 1.45 mmol) in CH2Cl2 (2 mL). The mixture was stirred for 40 min at −40 °C, and then a solution of 29 (2.3 g, 15 mmol) in CH2Cl2 (2 mL) was added. After 1.5 h, cumene hydroperoxide (6.5 mL, 44 mmol) was added dropwise over 3 min. The resulting solution was stirred for 89 h at −40 °C, then cooled to −78 °C and stirred for 10 min. Bu3P (7.27 mL, 28.0 mmol) was added dropwise over 10 min to quench the reaction. The mixture was stirred for 30 min, and was then treated with citric acid monohydrate (302 mg, 1.46 mmol) dissolved in acetone-ether (1:9, 21 mL). The cooling bath was removed, and the resulting mixture was stirred for an additional 40 min. After filtration through a pad of Celite, the filtrate was dried over MgSO4, concentrated and purified by silica gel flash column chromatography (33% EtOAc/hexanes) to furnish 2 g (79%) of the epoxide. To a 0 °C suspension of sodium hydride (0.46 g, 60 % in oil, 12 mmol) in THF (30 mL) was added a solution of the epoxide (2 g, 11.5 mmol) in THF (40 mL), followed by benzyl bromide (1.64 mL, 13.8 mmol) and tetrabutylammonium iodide (46 mg, 56.8 m mol). The mixture was stirred for 8 h at room temperature, and then water (50 mL) was added over 15 min. The phases were separated and the aqueous phase was further extracted with CH2Cl2. The combined organic extracts were washed with brine (50 mL), dried over sodium sulfate and concentrated under reduced pressure. Purification of the crude product by flash silica gel column chromatography (10% EtOAc/hexanes) provided 2.9 g (96% and 76% yield over two steps) of benzyl ether 30 as a colorless oil. (c 1.00, MeOH). 1H NMR (400 MHz, CDCl3) δ 7.26–7.31 (m, 5H), 1.33 (s, 3H), 4.53 (q, J = 6.4 Hz, 2H), 4.04 (t, J = 13.3 Hz, 1H), 3.82–3.89 (m, 2H), 3.77 (dd, J = 2.00, 11.6 Hz, 1H), 3.42 (dd, J = 5.6, 11.6 Hz, 1H), 3.07 (d, J = 2.5 Hz, 1H), 2.93 (d, J = 5.0 Hz, 1H,), 1.41 (s, 3H); 13C NMR (100 MHz, CDCl3) δ 137.8, 128.4, 127.7, 109.9, 75.5, 73.1, 69.4, 66.7, 55.8, 55.2, 26.5, 25.3; HRMS (ESI) calcd for [C15H20O4 + H]+ 265.1440, found 265.1446.

(S)-4-((1R,2R)-2-Azido-1,3-bis(benzyloxy)propyl)-2,2-dimethyl-1,3-dioxolane (31)

A solution of the epoxy alcohol 30 (2.2 g, 8.3 mmol) in a 2-methoxyethanol: water mixture (8:l, 94 mL) was refluxed for 5 h with sodium azide, (0.0289 g, 41.6 mmol) and ammonium chloride (0.019 g, 33 mmol). The reaction mixture was cooled to room temperature, concentrated under reduced pressure and the crude product was purified by flash silica gel column chromatography. To a suspension of NaH (0.30 g, 60 % in oil, 7.8 mmol) in THF (180 mL) was added a solution of the azide derivative (2.26 g, 7.4 mmol) in THF (40 mL), followed by benzyl bromide (1.00 mL, 0.0944 mmol). The mixture was stirred for 1.5 h at rt, and then H2O (50 mL) was added over 15 min. The phases were separated and the aqueous phase was further extracted with Et2O (2×100 mL). The combined organic extracts were washed with brine (50 mL), dried (MgSO4) and concentrated under reduced pressure. Purification of the crude product by silica gel flash column chromatography (6% EtOAc/hexanes) provided 2.6 g (78% yield over two steps) of compound 31 as colorless oil. (c 1.00, MeOH); 1H NMR (400 MHz, CDCl3) δ 7.33–7.37 (m, 10H), 4.70 (d t, J = 12.7 Hz, 6.04 Hz, 2H), 4.60 (d, J = 6.0 Hz, 6.4 Hz 2H), 4.20 (q, J = 6.3 Hz, 1H), 4.05 (dd, J = 6.4, 8.3 Hz, 1H), 3.90 (d, J = 2.2 Hz, 2H), 3.68–3.76 (m, 3H), 1.42 (s, 3H), 1.37 (s, 3H); 13C NMR (100 MHz, CDCl3) δ 137.7, 128.5, 128.5, 127.9, 127.7, 127.7, 109.3, 79.1, 75.2, 73.9, 73.4, 69.6, 66.5, 62.5, 26.6, 25.3; HRMS (ESI) calcd for [C22H27N3O4 + H]+ 398.2080, found 398.2076.

N-((1R,2R)-1,3-Bis(benzyloxy)-1-((S)-2,2-dimethyl-1,3-dioxolan-4-yl)propan-2-yl)-4-methylbenzenesulfonamide (32)

A solution of the azide 31 (2.4 g, 6.0 mmol) in THF (18 ml) was added dropwise to a stirred suspension of LiAlH4 in THF (2 M solution in THF, 13 mL, 13 mmol) at −78 °C under argon. The reaction mixture was stirred for 20 min, warmed up to 0 °C and then a 10% aqueous sodium solution was added dropwise and diluted with CH2Cl2. The biphasic system was stirred for 5 min and then separated. The aqueous phase was further extracted with chloroform and the combined organic phases were washed with brine and dried over sodium sulfate. Concentration of the organic layer under reduced pressure afforded the amine. The amine (2.12 g, 5.74 mmol) was taken into anhydrous CH2Cl2. Triethylamine (1.00 mL, 7.46 mmol) was added followed by tosyl chloride (1.42 g, 7.46 mmol) (as a solid) and stirred at room temperature for 4 h. Water was used to quench the reaction. The phases were separated and the aqueous phase was further extracted with CH2Cl2, dried over sodium sulfate and concentrated under reduced pressure. Purification of the crude product by silica gel flash column chromatography (30% EtOAc/hexanes provided 2.87 g (90%) of compound 32 as a colorless oil over two steps. (c 1.02, MeOH); 1H NMR (400 MHz, CDCl3) δ 7.64–7.67 (m, 2H), 7.13–7.28 (m, 12H), 4.72 (d, J = 11.2 Hz, 1H), 4.56 (d, J = 11.3 Hz, 1H), 4.20–4.28 (m, 3H), 3.97 (dd, J = 6.7, 8.0 Hz, 1H), 3.81–3.87 (m, 2H), 3.52 (dd, J = 4.5, 9.5 Hz, 1H), 3.35–3.38 (m, 1H), 3.14 (dd, J = 4.4, 9.5 Hz, 1H), 2.33 (s, 3H), 1.42 (s, 3H), 1.37 (s, 3H); 13C NMR (100 MHz, CDCl3) δ 143.4, 138.1, 137.6, 137.2, 129.5, 128.4, 127.9, 127.7, 127.1, 109.0, 78.1, 76.1, 74.7, 73.1, 67.4, 65.5, 54.6, 26.5, 25.1, 21.5; HRMS (ESI) calcd for [C29H35NO6S + H]+ 526.2263, found 526.2270.

N-((2R,3R,4S)-1,3-Bis(benzyloxy)-5-(tert-butyldimethylsilyloxy)-4-hydroxypentan-2-yl)-4-methylbenzenesulfonamide (33)

A solution of acetonide 32 (2.5 g, 4.8 mmol) was taken into a 1:1 solution of methanol and 2N HCl and stirred at 40 °C. The reaction was monitored by TLC and following completion was quenched by saturated solution of sodium bicarbonate, extracted with CH2Cl2, washed with brine and dried over MgSO4, concentrated in vacuum to give the crude product. The crude diol (2.4 g, 4.5 mmol) was taken into dry CH2Cl2. The solution was cooled to 0 °C and triethylamine (0.75 mL, 5.4 mmol) was added followed by t-butyldimethylsilyl chloride (1 M solution in CH2Cl2, 5.4 ml, 5.4 mmol) and a catalytic amount of DMAP. The reaction was stirred at 0 °C and after 1 h, water was added to quench the reaction. The reaction mixture was extracted with CH2Cl2, dried over sodium sulfate and concentrated under reduced pressure. Purification of the crude product was accomplished by silica gel flash column chromatography using 25% EtOAc/hexanes to provide compound 33 as a colorless oil in 85% yield (2.42 g). (c 0.67, MeOH); 1H NMR (400 MHz, CDCl3) δ 7.66 (d, J = 8.2 Hz, 2H), 7.13–7.28 (m, 12H), 4.57 (d, J = 4.8 Hz, 2H), 4.26 (d, J = 4.5 Hz, 2H), 3.65–3.77 (m, 4H), 3.55 (ddd, J = 5.3, 9.6, 18.9 Hz, 2H), 3.38 (dd, J = 5.2, 9.8 Hz, 1H), 2.31 (s, 3H), 0.88 (s, 9H), 0.01 (s, 6H); 13C NMR (100 MHz, CDCl3) δ 143.1, 138.3, 137.6, 137.5, 129.6, 128.9, 128.5, 128.1, 127.9, 127.3, 78.6, 73.8, 72.9, 71.6, 68.3, 63.6, 54.2, 25.9, 25.9, 21.5, 18.2, −5.4,−5.4; HRMS (ESI+) m/z calcd for [C32H45NO6SSi + H]+ 600.2815, found 600.2815.

(2R,3R,4R)-3-(Benzyloxy)-2-(benzyloxymethyl)-4-((tert-butyldimethylsilyloxy)methyl)azetidine (34)

Sulfonamide 33 (2.2 g, 3.67 mmol) and triphenylphosphine (1.45 g, 5.5 mmol) were dissolved in dry CH2Cl2 under argon/nitrogen. Diisopropyl azodicarboxylate (0.90 mL, 5.5 mmol) was added dropwise at 0 °C with stirring. The solution was warmed to room temperature and stirred for 16 h. The reaction mixture was then filtered through a pad of silica and concentrated in vacuo. The crude mixture was purified by flash silica gel column chromatography to yield the corresponding N-tosylazetidine as a colorless oil. 1.5 g (2.6 mmol) of the N-tosylazetidine was dissolved in dry DME (26 mL) and the resulting solution cooled to −60 °C. To this solution was added dropwise a dark-green solution of Na/naphthalene in a dry DME (0.25 M solution prepared by the addition of 0.89 g of Na in a 0.25 M solution of naphthalene (5 g) in DME until the dark-green color persisted. After 30 min, brine was added to the solution and the aqueous phase was extracted with EtOAc. The organic phase was dried (Na2SO4), concentrated in vacuum and the crude product filtered through a small pad of silica (5% EtOAc/hexanes to remove naphthalene and then pure EtOAc to elute azetidine 34 as a pale yellow oil in 70% yield over two steps (0.96 g). (c 0.67, MeOH); 1H NMR (400 MHz, CDCl3) δ 7.27–7.33 (m, 10H), 4.46–4.52 (m, 4H), 4.18–4.21 (m, 1H), 3.87–3.96 (m, 3H), 3.75 (d, J = 6.6 Hz, 1H), 3.47–3.49 (d, J = 4.1 Hz, 2H), 0.88 (s, 9H), 0.01 (s, 6H); 13C NMR (100 MHz, CDCl3) δ 138.2, 128.4, 127.7, 74.7, 73.3, 72.4, 71.8, 64.0, 62.3, 61.6, 25.9, 18.3, −5.4; HRMS (ESI) calcd for [C25H37NO3Si + H]+ 428.2621, found 428.2615.

((2R,3S,4R)-3-(Benzyloxy)-4-(benzyloxymethyl)-1-butylazetidin-2-yl)methanol (35a) and ((2R,3S,4R)-3-(Benzyloxy)-4-(benzyloxymethyl)-1-nonylazetidin-2-yl)methanol (35b)

The azetidine 34 (0.8 g, 1.9 mmol) and the aldehyde (butyraldehyde or nonyl aldehyde, 1.8 mmol ((0.16 mL for butyraldehyde and 0.30 mL for nonaldehyde) were mixed in ClCH2CH2Cl and then treated with solid sodium triacetoxyborohydride (0.57 g, 2.7 mmol). The mixture was stirred at rt under a nitrogen atmosphere for 16 h. The reaction mixture was quenched by adding aqueous saturated sodium bicarbonate. The product was extracted with CH2Cl2, dried over sodium sulfate, concentrated under reduced pressure, and purified by silica gel flash column chromatography. A mixture of the alkylated product, butyl derivative (0.69 g, 1.4 mmol) or nonyl derivative (0.81 g, 1.5 mmol) and TBAF (1 M in THF, 1.5 equiv, 2.25 ml) was stirred at room temperature for 4 h. The solvent was removed under reduced pressure and the crude product was purified by flash silica gel column chromatography using 100% EtOAc to provide compound 35a (0.5 g, 70% or 35b (0.6 g, 72%))) as a pale brown oil. 35a: (c 0.67, MeOH); 1H NMR (400 MHz, CDCl3) δ 7.24–7.34 (m, 10H), 4.44–4.61 (m, 4H), 4.22 (dd, J = 5.2, 6.8 Hz, 1H), 4.06 (dd, J = 5.1, 12.4 Hz, 1H), 3.90 (dd, J = 3.0, 12.4 Hz. 1H), 3.72–3.76 (m, 2H), 3.46–3.48 (m, 2H), 2.76–2.80 (m, 1H), 2.62–2.65 (m, 1H), 1.30–1.33 (m, 4H), 0.88 (t, J = 7.1 Hz, 3H); 13C NMR (100 MHz, CDCl3) δ 138.2, 137.6, 128.5, 128.4, 127.9, 127.7, 127.6, 74.9, 73.4, 71.8, 71.6, 71.1, 64.8, 60.4, 49.7, 31.5, 20.6, 14.1; HRMS (ESI) calcd for [C23H31NO3 + H]+ 370.2382, observed 370.2378.

35b: (c 0.40, MeOH); 1H NMR (400 MHz, CDCl3) δ 7.24–7.34 (m, 10 H), 4.45–4.60 (m, 4H), 4.24 (dd, J = 5.5, 6.3 Hz, 1H), 4.06 (dd, J = 5.1, 12.4 Hz, 1H), 3.92 (dd, J = 3.1, 12.5 Hz, 1H), 3.70–3.76 (m, 2H), 3.47–3.49 (m, 2H), 2.77–2.80 (m, 1H), 2.64–2.67 (m, 1H), 1.24–1.36 (m, 14H), 0.86 (t, J = 7.1 Hz, 3H); 13C NMR (100 MHz, CDCl3) δ 138.1, 137.6, 128.5, 127.9, 127.7, 74.6, 73.4, 71.9, 71.2, 71.0, 65.1, 60.2, 50.1, 31.8, 29.5, 29.3, 29.0, 27.4, 22.6,14.1; HRMS (ESI) calcd for [C28H41NO3 + H]+ 440.3165, found 440.3169.

((2R,4R)-1-Butyl-3-hydroxyazetidine-2,4-diyl)dimethanol (22) and ((2R,4R)-3-Hydroxy-1-nonylazetidine-2,4-diyl)dimethanol (23)

The dibenzyl compound (200 mg of 35a or 35b, 0.5 mmol and 0.45 mmol) was dissolved in methanol and palladium chloride (10 mol%) was added and the reaction mixture was subjected to hydrogenation (balloon) at room temperature for 4 h. The reaction mixture was filtered through Celite and the solvent removed under reduced pressure. The crude product was then washed with hexanes and dried over sodium sulfate to furnish compounds 22 and 23 as colorless oils in 65% (60 mg) and 70% yield (81 mg) respectively. 22: (c 0.20, MeOH); 1H NMR (400 MHz, DMSO-d6) δ 4.49 (t, J = 6.2 Hz, 1H), 4.06–4.23 (m, 3H), 3.80–3.91 (m, 3H), 3.15–3.23 (m, 2H), 1.49–1.59 (m, 2H), 1.3–1.32 (m, 2H), 0.88 (t, J = 7.3 Hz, 3H); 13C NMR (100 MHz, DMSO-d6) δ 77.1, 71.9, 64.3, 58.8, 57.6, 50.6, 28.4, 20.9, 13.9; HRMS (ESI) calcd for [C9H19NO3 + H]+ 190.1443, found 190.1445. 23: (c 0.60, MeOH); 1H NMR (400 MHz, DMSO-d6) δ 4.48 (t, J = 6.3 Hz, 1H), 4.06–4.18 (m, 3H), 3.77–3.91 (m, 3H), 3.12–3.19 (m, 2H), 1.50–1.57 (m, 2H), 1.19–1.22 (m, 12H), 0.78 −0.80 (t, 7.2 Hz, 3H); 13C NMR (100 MHz, DMSO-d6) δ 77.1, 71.7, 64.5, 59.1, 57.7, 50.1, 33.1, 30.5, 30.3, 30.2, 27.8, 26.6, 23.7, 14.4; HRMS (ESI) calcd for [C14H29NO3 + H]+ 260.2226, found 260.2225.

General procedures for compounds 37–41a, 41b, 24 and 25

The synthesis of compounds 37–41a, 41b, 24 and 25 (Scheme 8) follow the procedures for the synthesis of compounds 31–35a, 35b, 22 and 23 (Scheme 7).

(R)-4-((1R,2R)-2-Azido-1,3-bis(benzyloxy)propyl)-2,2-dimethyl-1,3-dioxolane (37)

Compound 36 was synthesized as described previously in the literature.36 Compound 37 was obtained as a colorless oil in 70%. (c 1.0, MeOH); 1H NMR (400 MHz, CDCl3) δ 7.29–7.37 (m, 10H), 4.55–4.73 (m, 4H), 4.25–4.28 (m, 1H), 3.98–4.02 (m, 1H), 3.70–3.82 (m, 3H), 3.54–3.60 (m, 2H), 1.42 (s, 3H), 1.37 (s, 3H); 13C NMR (100 MHz, CDCl3) 137.8, 137.6, 129.5, 128.4, 128.3, 127.8, 127.1, 109.3, 78.3, 74.5, 73.4, 69.1, 65.9, 62.1, 26.4, 25.6; HRMS (ESI) calcd for [C22H27N3O4 + H]+ 398.2080, found 398.2087.

N-((1R,2R)-1,3-Bis(benzyloxy)-1-((R)-2,2-dimethyl-1,3-dioxolan-4-yl)propan-2-yl)-4-methylbenzenesulfonamide (38)

Compound 38 was obtained as a colorless oil in 90%. (c 0.72, MeOH); 1H NMR (400 MHz, CDCl3) δ 7.65–7.68 (m, 2H), 7.17–7.32 (m, 12H), 4.24–4.46 (m, 4H), 4.10 (q, J = 7.15 Hz, 1H), 3.94 (dd, J = 6.6, 8.1 Hz, 1H), 3.53–3.65 (m, 3H), 3.43 (t, J = 4.88 Hz, 1H), 3.34 (dd, J = 7.02, 9.46 Hz, 1H), 2.31 (s, 3H), 1.39 (s, 3H), 1.30 (s, 3H); 13C NMR (100 MHz, CDCl3) δ ?143.2, 137.8, 137.4, 129.5, 128.4, 128.3, 127.8, 127.1, 109.4, 76.5, 73.2, 73.1, 68.8, 66.2, 60.3, 53.9, 26.2, 25.6, 21.4, 20.1, 14.2; HRMS (ESI) calcd for [C29H35NO6S + H]+ 526.2263, found 526.2267.

N-((2R,3R,4R)-1,3-Bis(benzyloxy)-5-(tert-butyldimethylsilyloxy)-4-hydroxypentan-2-yl)-4-methylbenzenesulfonamide (39)

Compound 39 was obtained as a colorless oil in 89%. (c 0.51, MeOH); 1H NMR (400 MHz, CDCl3) δ 7.66 (d, J = 8.2 Hz, 2H), 7.13–7.28 (m, 12H), 4.57 (d, J = 11.1 Hz, 2H), 4.25 (d, J = 4.5 Hz, 2H), 3.65–3.77 (m, 4H), 3.56 (ddd, J = 5.3, 9.6, 18.9 Hz, 2H), 3.38 (dd, J = 5.2, 9.8 Hz, 1H), 2.31 (s, 3H) 0.88 (s, 9H) 0.01 (s, 6H); 13C NMR (100 MHz, CDCl3) δ 143.3, 137.9, 137.5, 137.4, 129.6, 128.4, 128.3, 127.9, 127.8, 127.7, 127.1, 75.6, 73.5, 73.1, 70.3, 68.1, 63.1, 63.5, 60.3, 53.3, 25.9, 21.5, 21.1, 18.2, 14.2, −5.4; HRMS (ESI) calcd for [C32H45NO6SSi + H]+ 600.2815, found 600.2819.

(2R,3R,4S)-3-(Benzyloxy)-2-(benzyloxymethyl)-4-((tert-butyldimethylsilyloxy)methyl)azetidine (40)

Compound 40 was obtained as a colorless oil in 53%. (c 0.67, MeOH); 1H NMR (400 MHz, CDCl3) δ 7.20–7.29 (m, 10H), 4.41–4.52 (m, 4H), 3.79–3.86 (m, 3H), 3.76 (d, J = 6.6 Hz, 1H), 3.54–3.56 (m, 2H), 3.41–3.44 (m, 2H), 0.84 (s, 9H), 0.01 (6H); 13C NMR (100 MHz, CDCl3) δ 138.2, 128.4, 127.7, 74.7, 73.3, 72.4, 71.8, 64.0, 62.3, 61.6, 25.9, 18.3, −5.4; HRMS (ESI) calcd for [C25H37NO3Si + H]+ 428.2621, found 428.2621.

((2R,3S,4S)-3-(Benzyloxy)-4-(benzyloxymethyl)-1-butylazetidin-2-yl)methanol (41a)