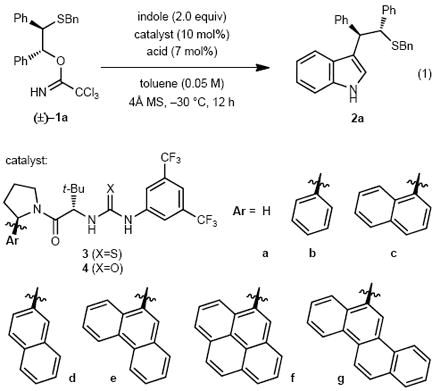

Table 1.

Reaction optimisation.a

| ||||

|---|---|---|---|---|

| entry | catalyst | acid | yield (%)b | ee (%)c |

| 1 | 3b | HCl | 10 | 5 |

| 2 | 3b | HOTf | 73 | 32 |

| 3 | 3b | FSO3H | 78 | 19 |

| 4 | 3b | 2,4-diNBSA | 79 | 63 |

| 5 | 3b | 4-NBSA | 72 | 73 |

| 6 | – | 4-NBSA | 7 | n/a |

| 7 | 3a | 4-NBSA | 16 | 12 |

| 8 | 3c | 4-NBSA | 84 | 84 |

| 9 | 3d | 4-NBSA | 80 | 85 |

| 10 | 3e | 4-NBSA | 93 | 93 |

| 11 | 3f | 4-NBSA | 91 | 91 |

| 12 | 3g | 4-NBSA | 97 | 88 |

| 13 | 4e | 4-NBSA | 98 | 92 |

Optimisation reactions were performed on 0.05 mmol scale.

Isolated yields of material purified chromatographically.

Enantiomeric excesses (ee’s) determined by HPLC analysis.

MS = molecular sieves; 2,4-diNBSA = 2,4-dinitrobenzenesulfonic acid; 4-NBSA = 4-nitrobenzenesulfonic acid.