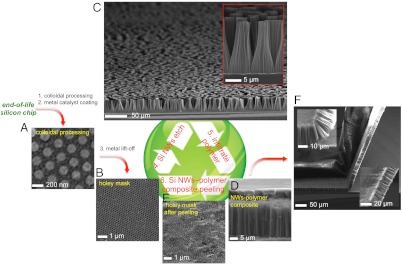

Fig. 1.

A second life for silicon: Si chip towards the Li-battery recycling wheel. Schematic of the Si-polymer composite fabrication: (A) colloidal polystyrene particles are self-assembled and processed on a Si chip to realize the (B) holey Au mask used to fabricate the (C) Si nanowires through MACE. Uniform diameter and length nanowires are obtained over large areas (Inset). (D) After the polymer/electrolyte infiltration, the composite is mechanically peeled to obtain the (F) self-supported Si nanowire-polymer composite. The fabricated composite membrane is highly flexible and can be bent with curvature radii less than 15 μm (Inset, see also Fig. 2C). (E) The holey catalyst mask remains intact after the peeling step and it is re-used for the fabrication of further Si nanowire-polymer composite membranes until the physical exhaustion of the Si chip.