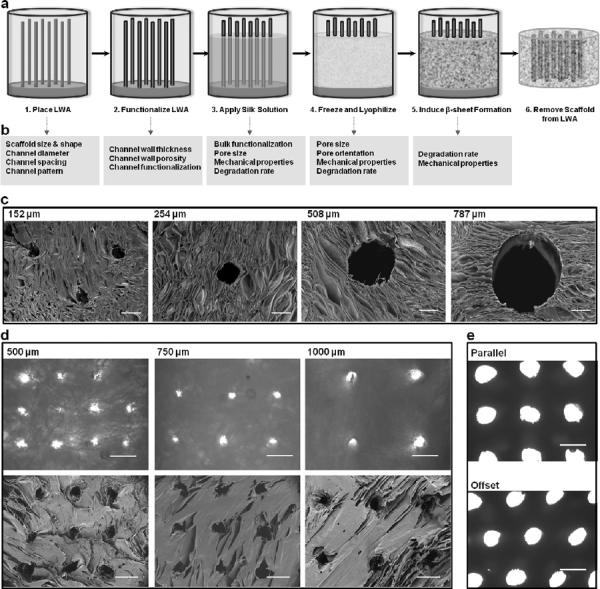

Figure 1. Silk scaffolds with hollow channels.

(a) Schematic of the fabrication process for building silk-based porous scaffolds containing hollow channels using a linear wire array (LWA). (b) At each step in the process there are avenues for tuning the scaffold bulk properties (e.g. porosity, mechanical stiffness, and degradation rate) and the hollow channel properties (e.g. diameter, spacing, bioactive agent functionalization and wall morphology). (c) SEM micrographs of channel diameters ranging from 152 μm to 787 μm in anisotropically frozen scaffolds. (d) Channel wall-to-wall spacing ranging between 500 μm and 1000 μm in isotropically frozen scaffolds. Top row shows brightfield light microscopy images, while the bottom row shows corresponding SEM images. (e) Channel patterning is shown in the parallel and offset configuration. Scale bars are (c) 200 μm, (d) 500 μm, and (e) 1 mm.