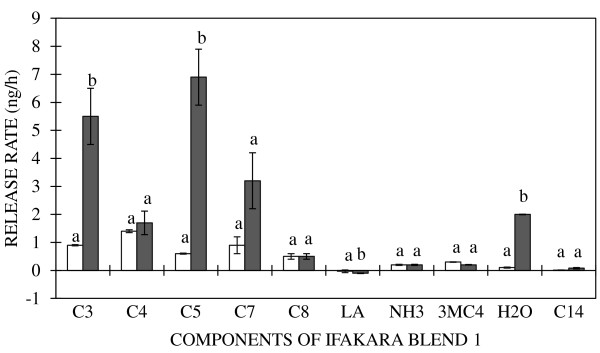

Figure 3.

Effect of LDPE sheet thickness on release rates of chemical constituents contained in the mosquito attractant Ifakara blend 1 (IB1). Release rates from sachets, the sheet thickness of which had been optimised for all chemicals components of the blend (open bars) or kept uniform (0.03 mm-sheets) for all the chemical constituents (shaded bars), are shown. The optimised LDPE sheet thicknesses were 0.2 mm [distilled water (H20), propionic (C3), butanoic (C4), pentanoic (C5), and 3-methylbutanoic acid (3MC4)], 0.1 mm [heptanoic (C7) and octanoic acid (C8)], 0.05 mm [lactic acid (LA)] and 0.03 mm [tetradecanoic acid (C14) and ammonia solution (NH3)]. Odour release rates represented by bars with different letters differ significantly (P < 0.05). Error bars represent the standard error of the mean odour release rates measured in ng/h.