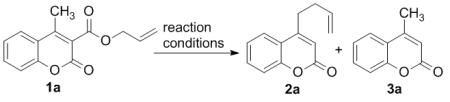

Table 1.

Optimization of Reaction Conditions.[a]

| Entry | Catalyst | Solvent | Yield (%)[b] | 2a:3a [b] |

|---|---|---|---|---|

| 1 | 5 mol% Pd(PPh3)4 | tol-d8 | 99 | 77:23 |

| 2 | 5 mol% Pd(PPh3)4 | CD3CN | 65 | 63:37 |

| 3 | 5 mol% Pd(PPh3)4 | DMF-d7 | 95 | 80:20 |

| 4 | 5 mol% Pd(PPh3)4 | THF-d8 | 87 | 83:17 |

| 5 | 3 mol% Pd2(dba)3, 6 mol% dppe |

tol-d8 | 75 | 70:30 |

| 6 | 3 mol% Pd2(dba)3, 6 mol% dppb |

tol-d8 | 67 | 77:23 |

| 7 | 3 mol% Pd2(dba)3, 6 mol% rac-BINAP |

tol-d8 | 77 | 70:30 |

| 8 |

3 mol% Pd2(dba)3,

6 mol% Xantphos |

tol-d8 | 99 | 94:6 |

| 9 | 3 mol% Pd2(dba)3, 6 mol% Xantphos |

DMF-d7 | 80 | 80:20 |

| 10 | 3 mol% Pd2(dba)3, 6 mol% dppf |

tol-d8 | 75 | 72:28 |

All reactions were carried out at 70 °C for 12 h, 0.1 mmol scale, 0.2 (M).

Yields and product distributions were determined by 1H NMR.