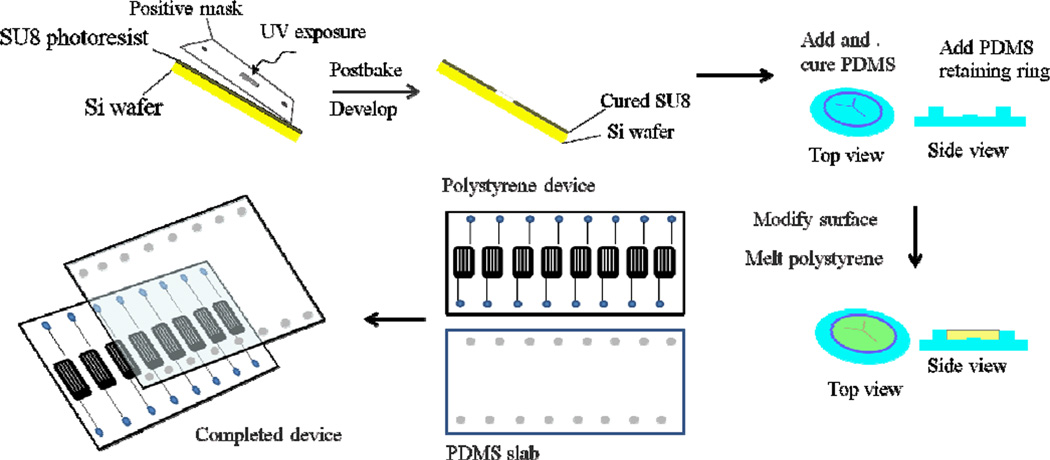

Fig. 1.

Fabrication of polystyrene devices with integrated channels. A silicon master is coated with SU-8 50 photoresist, and exposed to UV light through a positive photomask containing the serpentine features. The master is then developed and a PDMS replicate of the master is made. This PDMS mold is then sealed to a piece of glass, and a retaining ring of PDMS sealed along the outside. The PDMS is modified with 0.1 M (3-mercaptopropyl)-trimethylsiloxane, and polystyrene melted into the mold at 185 °C for 9 hours. The completed device is then removed and a PDMS cover slab with punched access holes is sealed to the polystyrene device through exposure to air plasma.