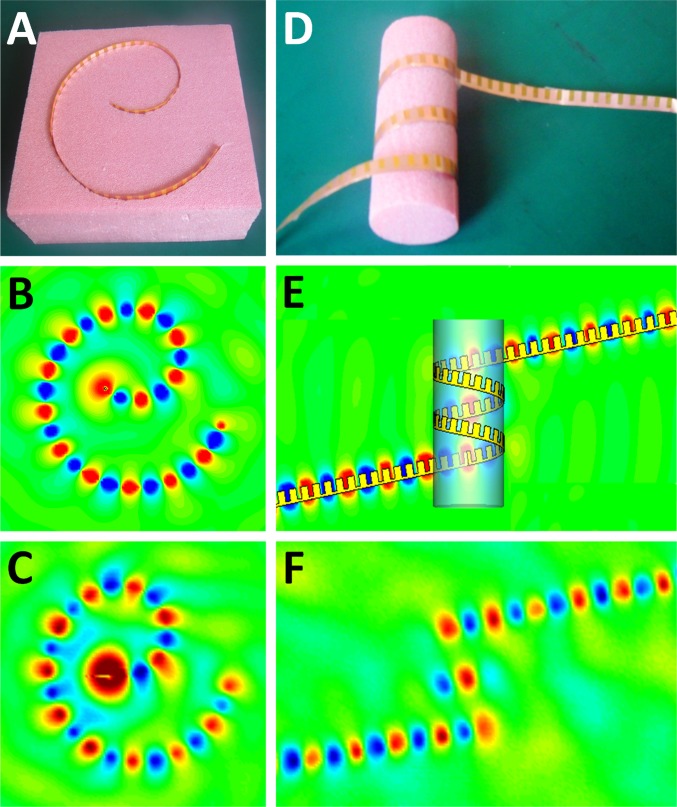

Fig. 5.

Simulation and measurement results of CSP waves on a spiral surface and a 3D helical-shaped curved surface. (A) Fabricated sample of the spiral-shaped ultrathin CSP film with an initial curvature radius of 20 mm and a maximum curvature radius of 40 mm, in which a = 2 mm, d = 5 mm, h = 4 mm, w = 5 mm, and t = 0.018 mm. The CSP film is supported by a foam substrate with nearly unity dielectric constant. (B and C) Full-wave simulation (B) and experimental (C) results of electric field distributions (Ey) at 11 GHz on the plane lying 1.5 mm above the spiral sample. An electric monopole perpendicular to the foam surface (Fig. S2B) was used to excite the CSP modes at the inner edge. (D) Fabricated sample of the ultrathin CSP film that is wrapped on a foam cylinder spirally at a bevel angle of 10°. The foam cylinder had a radius of 15 mm and was buried in the foam background to allow measurement of the fringe and pillar regions of the CSP strip. An electric monopole parallel to the corrugated film was used to excite the CSP modes at the left edge. (E) Full-wave simulation results of electric field distributions (Ez) along the 3D helix path at 11 GHz. (F) Experimental results of electric field distributions at 11 GHz on the plane lying 1.5 mm above the top of the foam cylinder. Excellent performance of the CSP propagation is observed along the helical-shaped surface in both the simulation and the measurement results.