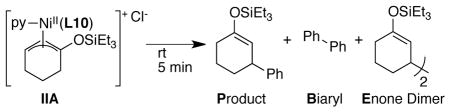

Table 4.

Stoichiometric Reactivity of Allylnickel IIA.a

| ||||||

|---|---|---|---|---|---|---|

| entry | conditionsb | Yield P (%) |

Yield B (%) |

Yield E (%) |

||

| PhI | Mn0 | Et3SiCl | ||||

| 1 | 0 | 0 | 0 | 0 | 0 | 0 |

| 2 | 100 | 0 | 0 | 12 | 0 | 0 |

| 3 | 100 | 0 | 110 | 7 | 0 | 0 |

| 4 | 100 | 110 | 200 | 71 | 0 | 0 |

| 5 | 1.0 | 110 | 200 | 28 | 0 | 0 |

| 6 | 100 | 0d | 0 | 26 | 0 | 0 |

| 7 | catalytic reaction with Ni(acac)2 and L10 | 99e | 0 | 13e | ||

| 8 | Catalytic reaction with Ni(acac)2, L10, and pyr | 69e | 0 | 14e | ||

Nickel complexes were generated in situ at a concentration of 2.5 mM in DMA and reacted with the noted reagents. Analysis at 5 minutes (GC, corrected) provided the stated yields. For stoichiometric reactions (1–6), the yield is calculated from starting nickel complex IIA.

Equivalents with respect to [Ni].

Mn0 powder was pre-stirred with Et3SiCl.

TDAE = tetrakis(dimethylamino)ethylene.

Yield calculated from the amount of enone added to catalytic reactions (0.5 mmol).