Abstract

The physicochemical and pasting properties of taro (Colocasia esculenta L.) flour were investigated and compared with flours from other botanical sources. Proximate composition, color parameters, water and oil absorption, foaming characteristics and pasting properties (measured using Rapid visco analyzer) of flours were related to each other using Pearson correlation and principal component analysis (PCA). Taro flour was significantly (P < 0.05) different from other flours in exhibiting highest carbohydrate, water absorption, and lower protein, foaming capacity and setback viscosity. Peak viscosity of taro flour was lower in comparison to potato flour but higher than that of soya and corn flours. Several significant correlations between functional and pasting properties were revealed both by PCA and Pearson correlation. PCA showed that taro and potato flours were located at the left of the score plot with a negative score, while soybean and corn flours had a large positive score in the first principal component.

Keywords: Flour, Taro, Functional, Physicochemical, Pasting, Potato

Introduction

Root and tuber crops are grown throughout the world in hot and humid regions and contain starch as the major carbohydrate in them. Tubers have a short-shelf life because of their high moisture content and start rotting as early as 2 weeks post-harvesting. In order to minimize tuber losses, they must be converted from perishable to non-perishable through food processing operations (Aboubakar et al. 2008). One of the best ways to preserve them is by processing them into flour and/or starch (Perez et al. 2005). Taro (Colocasia esculenta L.) is a tropical tuber crop largely produced for its underground corms and consumed in tropical and subtropical areas of the world (Aboubakar et al. 2008). Protein and fat content of taro are low but it is high in carbohydrates, fibre and minerals (Del Rosario and Lorenz 1999) and has been reported to have 70% to 80% starch (Jane et al. 1992).

Even though taro is not an industrial crop, its starch has numerous applications for use in several food products due to its small particle size which offer improved binding and may offer additional health promoting benefits. The high viscosity of taro starches makes them very useful in food applications where high thickening power is desired as well as the small particle size being useful for bread or noodle production (Aprianita et al. 2009). It has been reported that flour from taro corms, dried and milled contains easy digestion starch and therefore is widely used as infant food (Del Rosario and Lorenz 1999).

Successful performance of flours as food ingredients depend upon the functional characteristics and sensory qualities they impart to the end product (Kaur and Singh 2007). The functional properties of the flours are provided not only by proteins, but also by the complex carbohydrates and other components such as pectins and mucilages (Kaur and Singh 2005). Literature on taro has been reviewed by some authors (Mega 1992; Tagodoe and Nip 1994; Mbofung et al. 2006; Njintang and Mbofung 2006; Njintang et al. 2007). Attempts have been made to characterize taro starches and flours of Hawaiian and Cameroonian varieties but no such studies have been reported on Indian taro. The main objective of the present work was to study the functional and pasting properties of taro flour in comparison to other tuber (potato), cereal (corn) and legume (soyabean) flours. An acquisition of understanding of properties of taro flour may demonstrate its further potential uses in the food industry as an alternative source to conventional forms of carbohydrates or in production of new food products. Also the correlations between different flour properties were established using Pearson correlation and principal component analysis.

Materials and methods

Materials

Corn and soya flours were procured from local market of Amritsar, Punjab, India. For the production of taro flour, tubers of Colocasia were obtained from a local market, thoroughly washed in clean water, and kept at 4 °C until required for use. They were then peeled, sliced, blanched (at 90 °C for 2 min), dried at 50 °C in a hot air cabinet drier for 4 h and ground in a laboratory grinder. The ground materials were passed through sieve no. 72 (210 μm) to obtain flour. Potato flour was made by the same method as described for taro flour. All the flour samples were packed in air tight containers till further used.

Proximate composition

Flour samples were estimated for their moisture, ash, fat, and protein (N × 6.25) content by employing the standard methods of analysis (AOAC 1984).

Color characteristics

Color measurements of flour samples were carried out using a Hunter colorimeter Model D 25 optical Sensor (Hunter Associates Laboratory Inc., Reston, VA., U.S.A.) on the basis of L*, a* and b* values as described by Kaur and Singh (2005).

Bulk density

Flour samples were gently filled in 10 ml graduated cylinder, previously tared. The bottom of the cylinder was gently tapped on a laboratory bench several times until there was no further diminution of the sample level after filling to the 10 ml mark. Bulk density was calculated as weight of sample per unit volume of sample (g/ml). Measurements were made in triplicate.

Functional properties

Water and oil absorption

Water absorption of flours was measured by the centrifugation method of Sosulski (1962). The sample (3.0 g) was dispersed in 25 ml of distilled water and placed in preweighed centrifuge tubes. The dispersions were stirred occasionally, held for 30 min, followed by centrifugation for 25 min at 3000×g. The supernatant was decanted, excess moisture was removed by draining for 25 min at 50 °C, and sample was reweighed. For the determination of oil absorption the method of Lin et al. (1974) was used. Samples (0.5 g) were mixed with 6 ml of corn oil in preweighed centrifuge tubes. The contents were stirred for 1 min with a thin brass wire to disperse the sample in the oil. After a holding period of 30 min, the tubes were centrifuged for 25 min at 3000×g. The separated oil was then removed with a pipette and the tubes were inverted for 25 min to drain the oil prior to reweighing. The water and oil absorption capacities were expressed as grams of water or oil bound per gram of the sample on a dry basis.

Foaming capacity (FC) and foam stability (FS)

The capacity and stability of foams were determined by the method of Lin et al. (1974). 50 ml of a 3% (w/v) dispersion of flour sample in distilled water were homogenized using homogenizer (Yorco, India) at high setting for 2–3 min. The blend was immediately transferred into a graduated cylinder and the homogenizer cup was rinsed with 10 ml distilled water, which was then added to the graduated cylinder. The volume was recorded before and after whipping. FC was expressed as the volume increase (%) due to whipping. For the determination of FS, foam volume changes in the graduated cylinder were recorded at intervals of 20, 40, 60, and 120 min of storage. Triplicate determinations were carried out.

Pasting properties

Pasting properties of flours were studied by using Rapid Visco Analyzer (Newport Scientific Pty Ltd, Warriewood NSW 2102, Australia) as described by Kaur et al. (2007a). Viscosity profiles of flours were recorded using flours suspensions (8%; 28 g total weight).

Statistical analysis

The data reported in all the tables are average values of triplicate determinations. The data were subjected to one-way analysis of variance (ANOVA) using Minitab Statistical Software version 13 (Minitab Inc., State College, PA, USA). Pearson correlation coefficients (r) for relationships between various flour properties were calculated. The variations observed in the functional and pasting properties of the flours from different botanical sources were examined by principal component analysis (PCA) with the Minitab Statistical Software version 13. Using PCA, it was possible to reduce the dimension of the raw data and identify several correlations between various flour properties.

Results and discussion

Proximate composition

Proximate composition varied significantly (P < 0.05) among flours from different botanical sources (Table 1). Moisture content of all the flour samples was below 9%, thereby giving the flours a better shelf life. Moisture is an important parameter in the storage of flours, levels greater than 12% allow for microbial growth. Low levels are favorable and give relatively longer shelf life (Aryee et al. 2006). The results showed that carbohydrate was the most important chemical component in the flours while the protein (except soybean) and fat were very limited. Among all the flour samples, taro showed the highest carbohydrate content (95.7%), followed by potato (95.6%), whilst soya flour had the lowest value (61.3%). Taro is an important staple food in several regions of developing countries because it contains high amounts of carbohydrates and is an excellent energy supplier (Huang et al. 2007). The results also showed that besides carbohydrates, ash represents another important group of component in taro flour (1.2%), the value of which is comparable to that for potato (1.9%) but is higher compared to that of corn (0.71%) and lower than observed for soyabean (3.8%). Ash level in taro has been attributed to the presence of oxalates in taro (Aboubakar et al. 2008). Carbohydrate and ash contents of 84.6–91.5 g/100 g and 2–5 g/100 g flour have been observed earlier in taro grown in different regions of Thailand (Tattiyakul et al. 2005). Protein content of the flours varied widely ranging between 2.0% and 33.5% (Taro<Potato<Corn<Soya). The crude fat content of flours was 0.33–4.3%, potato exhibited the lowest whereas corn flour had the highest fat content. The fat content of soya flour was low as defatted flour was used in this study. Taro flour varied significantly (P < 0.05) from other flours with respect to its highest carbohydrate and the lowest protein content (2.0%). The results obtained for taro flour in the present study corroborated well with those reported by Aboubakar et al. (2008) for six varieties of Cameroon taro flour. These workers reported moisture, ash, fat, protein and carbohydrate contents in the range of 8.2–9.6%, 1.3–5.5%, 0.30–1.17%, 2.9–4.6% and 90.5–95.5%, respectively in taro flour.

Table 1.

Proximate composition, hunter color values and functional properties of flours from different botanical sources

| Parameter | Flour | |||

|---|---|---|---|---|

| Taro | Potato | Soyabean | Corn | |

| Moisture (%) | 7.7 ± 0.21bc | 7.5 ± 0.19b | 6.6 ± 0.23a | 8.4 ± 0.16c |

| Ash,% | 1.2 ± 0.12b | 1.9 ± 0.13c | 3.8 ± 0.19d | 0.71 ± 0.10a |

| Crude fat,% | 1.0 ± 0.08b | 0.33 ± 0.09a | 1.4 ± 0.07c | 4.3 ± 0.08d |

| Protein,% | 2.0 ± 0.52a | 2.2 ± 0.46a | 33.5 ± 0.89c | 3.2 ± 0.38b |

| Carbohydrate,% | 95.7c | 95.6c | 61.3a | 91.8b |

| Bulk density, g/ml | 0.689 ± 0.028b | 0.998 ± 0.016c | 0.539 ± 0.022a | 0.585 ± 0.020ab |

| Hunter L value | 85.5 ± 1.04ab | 86.1 ± 1.20b | 84.8 ± 1.01a | 84.4 ± 1.11a |

| Hunter a value | 1.5 ± 0.04c | −0.12 ± 0.01a | 0.58 ± 0.05b | 6.4 ± 0.04d |

| Hunter b values | 7.5 ± 0.14a | 12.6 ± 0.16b | 21.8 ± 0.12c | 31.6 ± 0.12d |

| ΔE value | 85.9 ± 1.3a | 87.0 ± 1.0ab | 87.6 ± 0.9b | 90.4 ± 1.2c |

| FC,% | 9 ± 1.0a | 40 ± 1.9c | 58 ± 2.5d | 18 ± 1.2b |

Mean ± SD with different superscripts in a row differ significantly (p < 0.05) (n = 3)

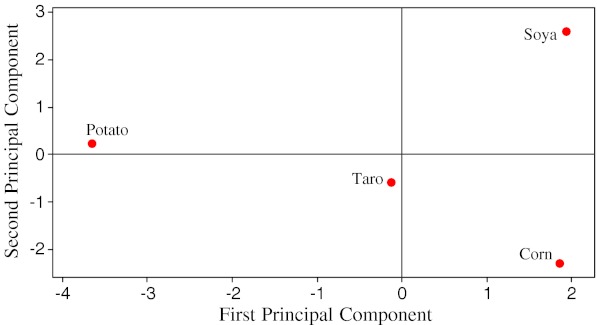

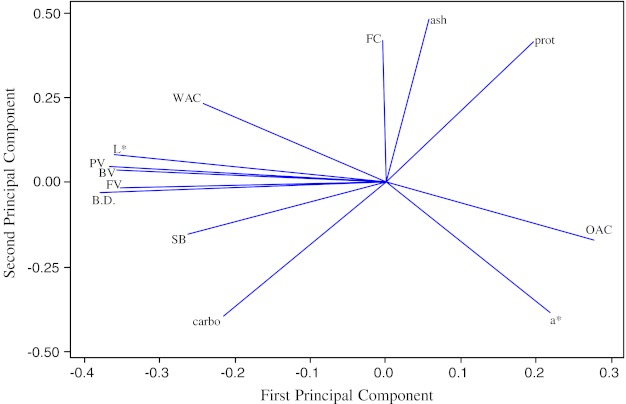

Principal component analysis (PCA) was used to visualize the variation in the properties among flours from different botanical sources. The results of the analysis are shown in Figs. 1 and 2. With this statistical method, a large number of variables are reduced to a few variables called principal components (PCs) that describe the greatest variance in the data analyzed. The PCA plots provide an overview of the similarities and differences between the flours and of the interrelationships between the measured properties. The distance between the locations of any two flours on the score plot is directly proportional to the degree of difference or similarity between them (Fig. 1). The first and the second PCs described 52.7 and 31.6% of the variance respectively. Together, the first two PCs represent 84.3% of the total variability. Taro and potato flours were located at the left of the score plot, while corn and soya flours had a large positive score in the first principal component (PC1) (Fig. 1). Potato flour had a large negative score whereas corn flour had a large positive score in PC1. Soya flour showed a large positive score while corn had a negative score in second principal component (PC2). Taro flour was located close to zero both in PC1 and PC2. The loading plot of the two PCs provided the information about correlations between the measured properties (Fig. 2). The properties whose curves lie close to each other on the plot are positively correlated while those whose curves run in opposite directions are negatively correlated.

Fig. 1.

Principal component analysis: score plot of first principal component (PC1) and second principal component (PC2) describing the overall variation among flours from different botanical sources

Fig. 2.

Principal component analysis: loading plot of PC1 and PC2 describing the variation among the properties of flours from different botanical sources. A heavy solid line and a second line very close to it indicate two properties that are highly correlated

Physicochemical properties

Significant differences were also observed for bulk density among flours from different botanical sources (Table 1). The bulk density (BD) measurements for different flours varied from 0.539 to 0.998 g/ml, the highest for potato and the lowest for soya flour were observed (Potato>Taro>Corn>Soya). BD is a reflection of the load the sample can carry if allowed to rest directly on another (Onimawo and Asugo 2004). The BD of flour could also be used to determine its packaging requirements (Akubor 2007). The BD of taro flour in the present study (0.689 g/ml) is similar to that observed earlier (0.57–0.71 g/ml) by Njintang et al. (2007) but higher (0.43–0.49 g/ml) than that reported by Tagodoe and Nip (1994). PCA analysis revealed a negative correlation of bulk density with ash and protein and a positive with carbohydrate content (Fig. 2). The hunter color characteristics (L*, a*, b*) of the flours samples are grouped in Table 1. Significant differences were observed between the different color parameters. The L* values for different flours varied between 84.4 and 86.1, the highest for potato and the lowest for corn flour was observed. The L* values for taro and soya flour were 85.5 and 84.8, respectively. Hunter a* and b* values for the flours ranged between −0.12 to 6.4 and 7.5 to 31.6, respectively. L* and a* values run in opposite direction on PCA loading plot, suggesting a negative correlation between them (Fig. 2). The results showed that taro and potato flour were light (high value of L*), and less yellow (low b* value) whereas corn flour was darker (lowest L* value), with the highest a*and b* value (more reddish yellow). Taro flour has been reported to be white, less red and less yellow in color (Aboubakar et al. 2008). It has been hypothesized that the variation in b* value among samples may be attributed to the amount of carbohydrate and protein content (Jamin and Flores 1998). The total colour difference (∆E) of the flours ranged from 85.9 to 90.4. The difference in the colour characteristics of different flours may be attributed to differences in coloured pigments of the flours, which in turn depends on the botanical origin of the plant and also to the composition of the flour (Aboubakar et al. 2008).

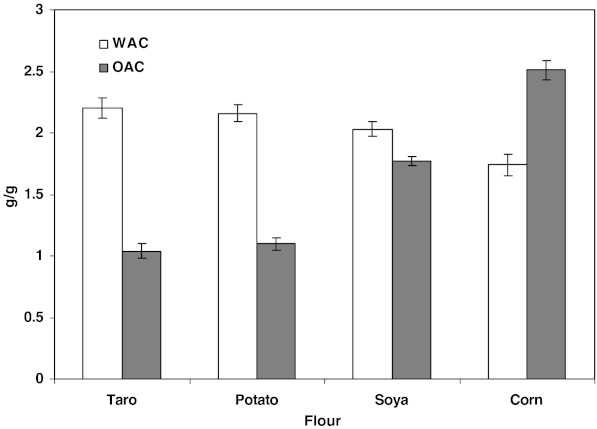

Functional properties

The variation in the water absorption capacity (WAC) and oil absorption capacity (OAC) among the different flours is given in Fig. 3. The results indicated that taro flour exhibited the highest WAC (2.2 g/g), followed by potato (2.16 g/g), soya (2.06 g/g) while the lowest was observed for corn flour (1.74 g/g). WAC of 270–375 g/100 g and 150–180% for taro cultivated in Camerron (Njintang et al. 2007) and in Hawaii (Tagodoe and Nip 1994), respectively, 2.17 g/g for soybean flour (Akubor 2007), 2.4 g/g for moth bean flour (Pawar and Ingle 1988), and 2.17 g/g for soybean meal (Sharma and Subramanian 1994) has been reported earlier. Water absorption characteristics represent the ability of a product to associate with water under conditions where water is limiting (Singh 2001). The high WAC of taro flour could be attributed to the presence of higher amount of carbohydrates in this flour. Aboubakar et al. (2008) suggested that the non-starch component of the flours such as mucilage contribute highly to the water absorption of taro flour. The good WAC of taro flour may prove useful in enhancing the applicability of this flour in products where good viscosity is required, such as in soups and gravies. The OAC of different flours ranged from 1.04 to 2.51 g/g (Fig. 3). OAC is of great importance from an industrial viewpoint, since it reflects the emulsifying capacity (Kaur et al. 2007b). WAC of 2.49 ml/g and OAC of 1.06 ml/g in taro flours have been reported by Iwuoha and Kalu (1995). The ability of flours to absorb and retain water and oil may help improve binding of the structure, enhance flavor retention, improve mouthfeel and reduce moisture and fat losses of extended meat products (McWatters and Heaton 1979). A significant negative correlation of WAC with OAC has been revealed both by Pearson correlation (r = −0.987, p < 0.01) (Table 2) and PCA analysis (Fig. 2). WAC showed a positive correlation with Hunter L* (r = 0.851, p < 0.05) and negative with fat (r = −0.960, p < 0.01) content (Table 2).

Fig. 3.

Water absorption capacity (WAC) and oil absorption capacity (OAC) of flours from different botanical sources. Error bars: Standard deviations. Results are means of triplicate determinations

Table 2.

Pearson correlation coefficients between various functional, thermal and pasting properties of flours from botanical sources

| Fat | L* | b* | WAC | OAC | FC | PV | TV | BV | FV | |

|---|---|---|---|---|---|---|---|---|---|---|

| L* | −0.850* | |||||||||

| b* | 0.871* | −0.855* | ||||||||

| WAC | −0.960** | 0.851* | −0.971** | |||||||

| OAC | 0.933** | −0.911* | 0.985** | −0.987** | ||||||

| FC | −0.346 | 0.008 | 0.154 | 0.087 | 0.013 | |||||

| PV | −0.609 | 0.852* | −0.460 | 0.497 | −0.577 | 0.229 | ||||

| TV | −0.635 | 0.872* | −0.495 | 0.530 | −0.608 | 0.217 | 0.999** | |||

| BV | −0.543 | 0.798 | −0.372 | 0.415 | −0.496 | 0.257 | 0.995** | 0.991** | ||

| FV | −0.450 | 0.757 | −0.309 | 0.332 | −0.426 | 0.184 | 0.982** | 0.975** | 0.993** | |

| SB | −0.013 | 0.411 | 0.110 | −0.115 | 0.002 | 0.090 | 0.799 | 0.777 | 0.847* | 0.897* |

WAC water absorption capacity; OAC oil absorption capacity; FC foaming capacity; PV peak viscosity; TV trough viscosity; BV breakdown viscosity; FV final viscosity; SB setback viscosity. *p < 0.05, **p < 0.01

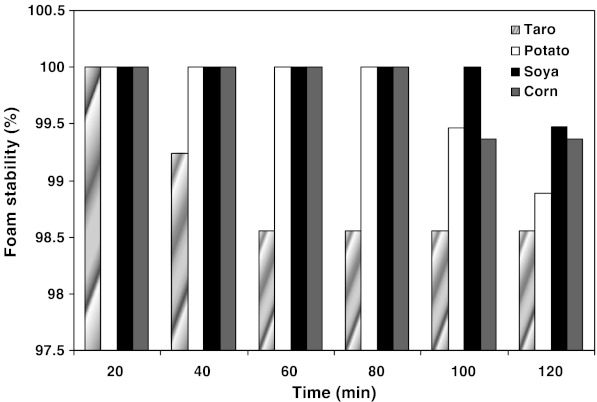

The foaming capacity (FC) and foam stability (FS) varied significantly (P < 0.05) among the flours. Foams are used to improve texture, consistency and appearance of foods (Akubor 2007). FC was calculated as% increase in volume of protein dispersion upon mixing. FC of flours varied from 12 to 58% (Table 1), and followed the order: Soya>Potato>Corn>Taro. FC of 29–31 ml/100 ml (Tagodoe and Nip 1994) and 18–27 ml/100 ml (Njintang et al. 2007) in taro flour has been observed earlier. The FC of taro flour could be due to its mucilage (a soluble glycoprotein) content (Tagodoe and Nip 1994). The foaming of flours has always been thought to be due to proteins which form a continuous cohesive film around the air bubbles in the foam (Njintang et al. 2001). A positive correlation of FC with protein content can be observed in the PCA loading plot (Fig. 2). Oil interferes with the foaming properties of proteins (Akubor 2005). Foam volume changes as a function of time for various flours are shown in Fig. 4. In all the flours, FC tended to decrease with the passage of time but the rate of decrease varied with the kind of flour. All the flours had FS of 100% till 20 min and >90% till 120 min of storage and followed the order: Soya>Corn>Potato>Taro. FS is important since the usefulness of whipping agents depends on their ability to maintain the whip as long as possible (Lin et al. 1974).

Fig. 4.

Foam stability of flours from different botanical sources after 20, 40, 60, 90, and 120 min of storage. Results are means of triplicate determinations

Pasting properties

The pasting characteristics of taro, corn, potato and soya flours determined by Rapid visco analyzer (RVA) are presented in Table 3. Significant differences were observed among the flours tested in their behaviour during heating and cooling cycles in excess of water. Peak viscosity (PV) ranged between 959 and 9264 cP and followed the order: Potato>Taro>Soya>Corn. PCA loading plot revealed a negative correlation between PV and protein content of the flours (Fig. 2). Swelling power of flours is related to their protein and starch contents. High protein content in flour may cause the starch granules to be embedded within a stiff protein matrix which subsequently limits the access of the starch to water and restricts the swelling power (Aprianita et al. 2009). The low protein and high carbohydrate contents of potato and taro flours resulted in their higher swelling ability. Bonding forces within granule could also affect their swelling behavior. The weaker bonding forces in potato permit higher swelling and consequently its higher PV than the stronger bonding forces in corn flour. PV often correlates with the quality of end-product and also provides an indication of the viscous load likely to be encountered by a mixing cooker (Ragaee and Abdel-Aal 2006). A highly significant positive correlation of PV and Trough viscosity (TV) has been observed through Pearson correlation (p < 0.01, Table 2). Breakdown viscosity (BV) of flours ranged between 192 and 2,517 cP, the lowest for soya and the highest for potato flour was observed. The pasting characteristics play an important role in the selection of a variety for use in the industry as a thickener, binder or for any other use. Viscosity of the gel formed during and after heating is an important factor in the selection process (Aryee et al. 2006). Final viscosity (FV) and set back viscosity (SB) varied between 1832 cP to 10284 cP and 560 cP to 3537 cP, respectively. Potato flour showed significantly higher FV and SB, followed by corn, taro and soya flours. SB is measure of syneresis of starch upon cooling of cooked starch pastes (Singh et al. 2004). A retrogradation tendency in taro flour has been reported earlier (Aprianita et al. 2009; Zaidul et al. 2007). In comparison to other flours, taro exhibited lower SB thereby indicating its lower tendency to retrograde. Pearson correlation analysis used to explore interrelationships amongst the various RVA viscosity attributes suggested a positive correlation of PV with BV (r = 0.995) and FV (r = 0.982) (Table 2). BV was positively correlated to FV (r = 0.993), TV (r = 0.991) and SB (r = 0.847). Also, the PV, BV and FV values run in same directions on the PCA loading plot, suggesting a positive correlation between them (Fig. 2). A negative correlation of RVA viscosity attributes with the protein and a positive with carbohydrate contents was observed. Although starch is quantitatively major component to control the pasting/thermal properties, temperature induced changes in non starchy polysaccharides and proteins also contribute to the gelling, and pasting properties by way of swelling, denaturation and unfolding (Kaur and Sandhu 2010). Pasting viscosity of flour has been reported to be influenced by its starch (Ragaee and Abdel-Aal 2006), protein (Zaidul et al. 2007) and lipid (Russell 1987) contents and the degree of starch damage during processing of flours.

Table 3.

Pasting properties of flours from different botanical sources

| Cultivar | PV, cP | TV, cP | BV, cP | FV, cP | SB, cP |

|---|---|---|---|---|---|

| Taro | 1958 ± 62c | 1741 ± 46c | 217 ± 26a | 2301 ± 34b | 560 ± 16a |

| Potato | 9264 ± 74d | 6747 ± 69d | 2517 ± 44b | 10284 ± 83d | 3537 ± 42d |

| Soyabean | 1314 ± 33b | 1122 ± 38b | 192 ± 25a | 1832 ± 29a | 710 ± 19b |

| Corn | 959 ± 41a | 764 ± 27a | 195 ± 16a | 2964 ± 43c | 2200 ± 31c |

Mean ± SD with different superscripts in a column differ significantly (p < 0.05) (n = 3)

PV peak viscosity, TV trough viscosity, BV breakdown viscosity, FV final viscosity, SB setback viscosity

Conclusion

The chemical composition and functional properties of taro flour differed significantly from flours of other botanical sources. The results pointed out that taro flour exhibited highest WAC and lowest foaming capacity in comparison to other flours. The high WAC and peak viscosity of taro flour makes it a good body providing agent and can thus be used as a thickener or gelling agent in various food products. The paste formed by taro flour as a result of heating was stable upon cooling as was evident by its lower setback viscosity. This is advantageous in formulations where starch stability is required at low temperatures. Based on the results, taro flour has a good potential to be used in food industry either for development of new food products or for the replacement in current food products made from conventional flour sources.

References

- Aboubakar NYN, Scher J, Mbofung CMF. Physicochemical, thermal properties and micro structure of six varieties of taro (Colocasia esculenta L. Schott) flours and starches. J Food Eng. 2008;86:294–305. doi: 10.1016/j.jfoodeng.2007.10.006. [DOI] [Google Scholar]

- Akubor PI. Effects of defatting on chemical, functional and storage properties of melon (Colocynthis citrullus) seed flour. J Food Sci Technol. 2005;42:472–474. [Google Scholar]

- Akubor PI. Chemical, functional and cookie baking properties of soybean/maize flour blends. J Food Sci Technol. 2007;44(6):619–622. [Google Scholar]

- Official methods of analysis. 14. Arlington: Association of Official Analytical chemists; 1984. [Google Scholar]

- Aprianita A, Purwandari U, Watson B, Vasiljevic T. Physico-chemical properties of flours and starches from selected commercial tubers available in Australia. Food Res Int. 2009;16:507–520. [Google Scholar]

- Aryee FNA, Oduro I, Ellis WO, Afuakwa JJ. The physicochemical properties of flour samples from the roots of 31 varieties of cassava. Food Control. 2006;17:916–922. doi: 10.1016/j.foodcont.2005.06.013. [DOI] [Google Scholar]

- Del Rosario AV, Lorenz K. Pasta products containing taro (Colocasia esculenta L. Schott) and chaya (Cnidoscolus Chayamansa L. Mcvaugh) J Food Process Preserv. 1999;23:1–20. doi: 10.1111/j.1745-4549.1999.tb00366.x. [DOI] [Google Scholar]

- Huang CC, Chen WC, Wang CCR. Comparison of Taiwan paddy- and upland-cultivated taro (Colocasia esculenta L.) cultivars for nutritive values. Food Chem. 2007;102:250–256. doi: 10.1016/j.foodchem.2006.04.044. [DOI] [Google Scholar]

- Iwuoha CI, Kalu FA. Calcium oxalate and physico-chemical properties of cocoyam (Colocasia esculenta & Xanthosoma saggittfolium) tuber flours as affected by processing. Food Chem. 1995;54:61–66. doi: 10.1016/0308-8146(95)92663-5. [DOI] [Google Scholar]

- Jamin FF, Flores RA. Effect of additional separation and grinding on the chemical and physical properties of selected corn dry-milled streams. Cereal Chem. 1998;75:166–170. doi: 10.1094/CCHEM.1998.75.1.166. [DOI] [Google Scholar]

- Jane JL, Shen L, Lim S, Kasemsuwan T, Nip WK. Physical and chemical studies of taro starches and flours. Cereal Chem. 1992;69:528–535. [Google Scholar]

- Kaur M, Sandhu KS. Functional, thermal and pasting characteristics of flours from different lentil (Lens culinaris) cultivars. J Food Sci Technol. 2010;47:273–278. doi: 10.1007/s13197-010-0042-0. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kaur M, Singh N. Studies on functional, thermal and pasting properties of flours from different chickpea (Cicer arietinum L.) cultivars. Food Chem. 2005;91:403–411. doi: 10.1016/j.foodchem.2004.06.015. [DOI] [Google Scholar]

- Kaur M, Singh N. Relationships between various functional, thermal and pasting properties of flours from different Indian Black gram (Phaseolus mungo L.) cultivars. J Sci Food Agric. 2007;87:974–984. doi: 10.1002/jsfa.2789. [DOI] [Google Scholar]

- Kaur M, Sandhu KS, Singh N. Comparative study of the functional, thermal and pasting properties of flours from different field pea and pigeon pea cultivars. Food Chem. 2007;104:259–267. doi: 10.1016/j.foodchem.2006.11.037. [DOI] [Google Scholar]

- Kaur M, Singh N, Sandhu KS. Preparation and characterization of protein isolates from different lentil (Lens culinaris) cultivars. J Food Sci Technol. 2007;44:327–329. [Google Scholar]

- Lin MJY, Humbert ES, Sosulski FW. Certain functional properties of sunflower meal products. J Food Sci. 1974;39:368–371. doi: 10.1111/j.1365-2621.1974.tb02896.x. [DOI] [Google Scholar]

- Mbofung CMF, Aboubakar NYN, Abdou Bouba A, Balaam F. Physicochemical and functional properties of six varieties of taro (Colocasia esculenta L. Schott) flour. J Food Technol. 2006;4:135–146. [Google Scholar]

- McWatters KH, Heaton K. Quality characteristics of ground beef patties extended with moist-heated and unheated seed meals. J Am Oil Chem Soc. 1979;56:86A–90A. doi: 10.1007/BF02671790. [DOI] [Google Scholar]

- Mega JA. Taro: composition and food uses. Food Rev Int. 1992;8:443–473. doi: 10.1080/87559129209540948. [DOI] [Google Scholar]

- Njintang NY, Mbofung CMF. Effect of precooking time and drying temperature on the physicochemical characteristics and in vitro carbohydrate digestibility of taro flour. Lebensm-Wiss Technol. 2006;39:684–691. doi: 10.1016/j.lwt.2005.03.022. [DOI] [Google Scholar]

- Njintang NY, Mbofung CMF, Waldron KW. In vitro protein Digestibility and physicochemical properties of dry red bean flour (Phaseolus vulgaris) flour: effect of processing and incorporation of soybean and cowpea flour. J Agric Food Chem. 2001;49:2465–2471. doi: 10.1021/jf0011992. [DOI] [PubMed] [Google Scholar]

- Njintang YN, Mbofung CMF, Moates KG, Parker L, Fauld CB, Smith AC. Functional properties of five varieties of taro flour and relationship to creep recovery and sensory characteristics of achu (taro based paste) J Food Eng. 2007;82:114–120. doi: 10.1016/j.jfoodeng.2006.12.023. [DOI] [Google Scholar]

- Onimawo IA, Asugo S. Effects of germination on the nutrient content and functional properties of pigeon pea flour. J Food Sci Technol. 2004;41(2):170–174. [Google Scholar]

- Pawar VD, Ingle UM. Functional properties of raw and cooked moth bean (Phaseolus acontifolius Jacq) flours. J Food Sci Technol. 1988;25(4):186–189. [Google Scholar]

- Perez E, Schultzb FS, Pacheco de Delahaye E. Characterization of some properties of starches isolated from Xanthosoma Saggitifolium (tannia) and Colocasia esculenta (taro) Carbohydr Polym. 2005;60:139–145. doi: 10.1016/j.carbpol.2004.11.033. [DOI] [Google Scholar]

- Ragaee S, Abdel-Aal EM. Pasting properties of starch and protein in selected cereals and quality of their food products. Food Chem. 2006;95:9–18. doi: 10.1016/j.foodchem.2004.12.012. [DOI] [Google Scholar]

- Russell PL. The aging of gels from starches of different amylose/amylopectin content studied by differential scanning calorimetry. J Cereal Sci. 1987;6:147–158. doi: 10.1016/S0733-5210(87)80051-6. [DOI] [Google Scholar]

- Sharma YK, Subramanian N. Comparative studies on functional properties of Soymeals from ‘Kalitur’ and ‘Bragg’ varieties. J Food Sci Technol. 1994;31(1):27–31. [Google Scholar]

- Singh U. Functional properties of grain legume flours. J Food Sci Technol. 2001;38:191–199. [Google Scholar]

- Singh N, Kaur M, Sandhu KS, Guraya HS. Physicochemical, thermal, morphological and pasting properties of starches from some Indian black gram (Phaseolus mungo L.) varieties. Starch. 2004;56:535–544. doi: 10.1002/star.200400290. [DOI] [Google Scholar]

- Sosulski FW. The centrifuge method for determining flour absorption in hard red spring wheats. Cereal Chem. 1962;39:344–350. [Google Scholar]

- Tagodoe A, Nip WK. Functional properties of raw and precooked taro (Colocasia esculenta) flours. Int J Food Sci Technol. 1994;29:457–462. doi: 10.1111/j.1365-2621.1994.tb02087.x. [DOI] [Google Scholar]

- Tattiyakul J, Asavasaksakul S, Pradipasena P. Chemical and physical properties of flour extracted from taro (Colocasia esculenta L. Schott) grown in different regions of Thailand. Sci Asia. 2005;32:279–284. doi: 10.2306/scienceasia1513-1874.2006.32.279. [DOI] [Google Scholar]

- Zaidul ISM, Norulaini NAN, Omar AKM, Yamauchi H, Noda T. RVA analysis of mixtures of wheat flour and potato, sweet potato, yam and cassava starches. Carbohydr Polym. 2007;69:784–791. doi: 10.1016/j.carbpol.2007.02.021. [DOI] [Google Scholar]